Smart factory solutions represent the next evolution in manufacturing, where digital factory technologies, data integration, and automation come together to drive efficiency. As of 2019, 68% of manufacturers worldwide had started digital transformation projects, marking a rapid shift from traditional to digital factory models. Industry 4.0 and 4.0 initiatives use IoT, AI, and real-time analytics to enable interconnected, agile production lines. The table below highlights the key differences between traditional and smart manufacturing:

| Aspect | Traditional Manufacturing | Smart Manufacturing (Digital Factory) |

|---|---|---|

| Automation | Minimal, manual processes | High automation, quick reconfiguration |

| Data Utilization | Limited, historical | Real-time, actionable insights |

| Efficiency | Reactive, frequent downtime | Predictive, optimized, less downtime |

| Quality Control | Post-production checks | AI-driven, real-time monitoring |

You can leverage solutions like FanRuan’s FineReport and FineVis to accelerate your digital factory journey. Consider how embracing a smart factory can solve operational challenges and push your digital transformation forward.

A smart factory is a modern manufacturing environment where machines, devices, and systems connect and communicate with each other. You see real-time data flowing across the entire digital factory, from the shop floor to the management office. Industry leaders describe the smart factory as the heart of 4.0, where technologies like the Industrial Internet of Things (IIoT), artificial intelligence, robotics, and cloud computing work together. These technologies help you collect, analyze, and use data to improve every step of the manufacturing process.

In a smart factory, you move beyond simple automation. You gain a digital factory that learns and adapts. Machines and systems share information instantly, allowing you to spot problems early and make quick decisions. You can use AI and big data analytics to predict equipment failures or adjust production schedules. This approach helps you reduce downtime, improve product quality, and respond faster to customer needs.

The journey to a smart factory often follows four stages:

Even with advanced automation, your team still plays a key role. People interpret data, manage exceptions, and guide the digital transformation. The smart factory connects the physical and digital worlds, making your manufacturing process more flexible, efficient, and resilient.

Smart factory solutions bring together the best of digital factory technology to help you transform your operations. These solutions focus on making your manufacturing process smarter, faster, and more reliable. Here are the key features you should look for:

Tip: Smart factory solutions help you move from a reactive approach to a proactive one. You can predict and prevent problems instead of just reacting to them.

Smart factory solutions also improve your manufacturing process in several ways:

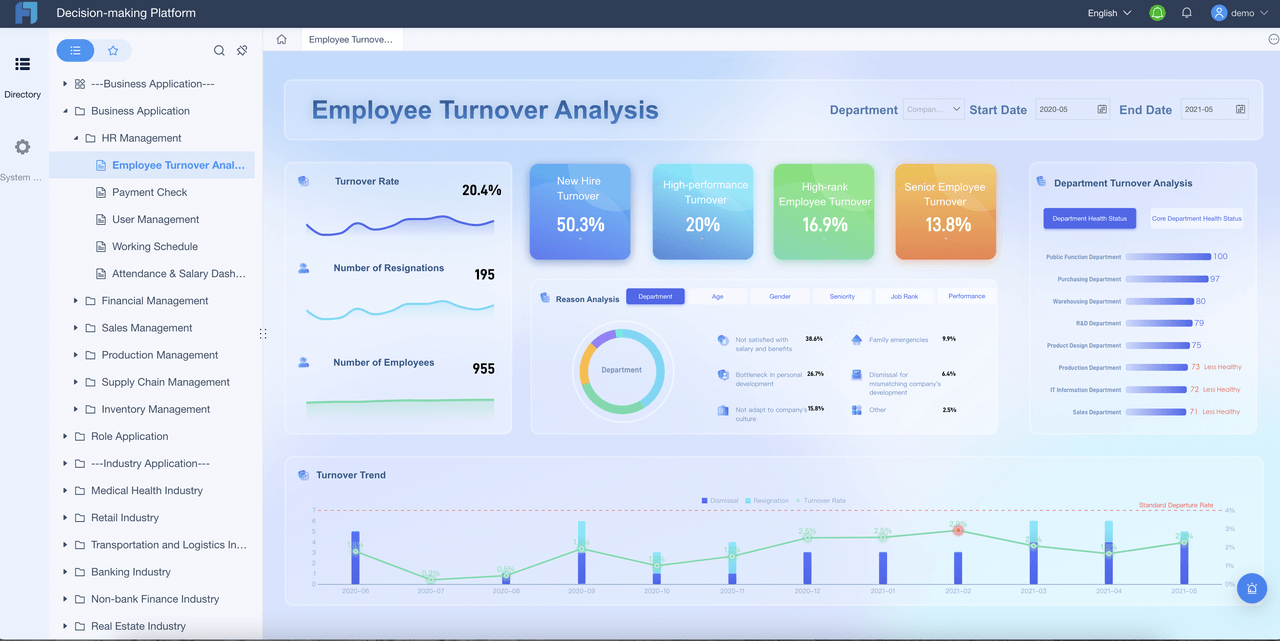

You can see these benefits in action when you use platforms like FanRuan. FanRuan supports your smart factory transformation with end-to-end digital factory solutions. You get tools for production, supply chain, sales, research and development, HR, and finance. Their business intelligence platforms, such as FineReport and FineVis, help you analyze data, manage resources, and make smarter decisions. With these solutions, you accelerate your digital transformation and unlock the full potential of your digital factory.

| Feature | How It Helps You |

|---|---|

| Prioritization | Focus on the most important production issues |

| Prescription | Take the right actions based on data insights |

| Integration | Connect all systems for a unified digital factory |

| Prediction | Anticipate problems before they disrupt production |

| Automation | Streamline tasks and reduce manual work |

Smart factory solutions give you the tools to modernize your manufacturing process. You gain a competitive edge by improving efficiency, quality, and agility. As you adopt these digital factory technologies, you prepare your business for the future of smart manufacturing.

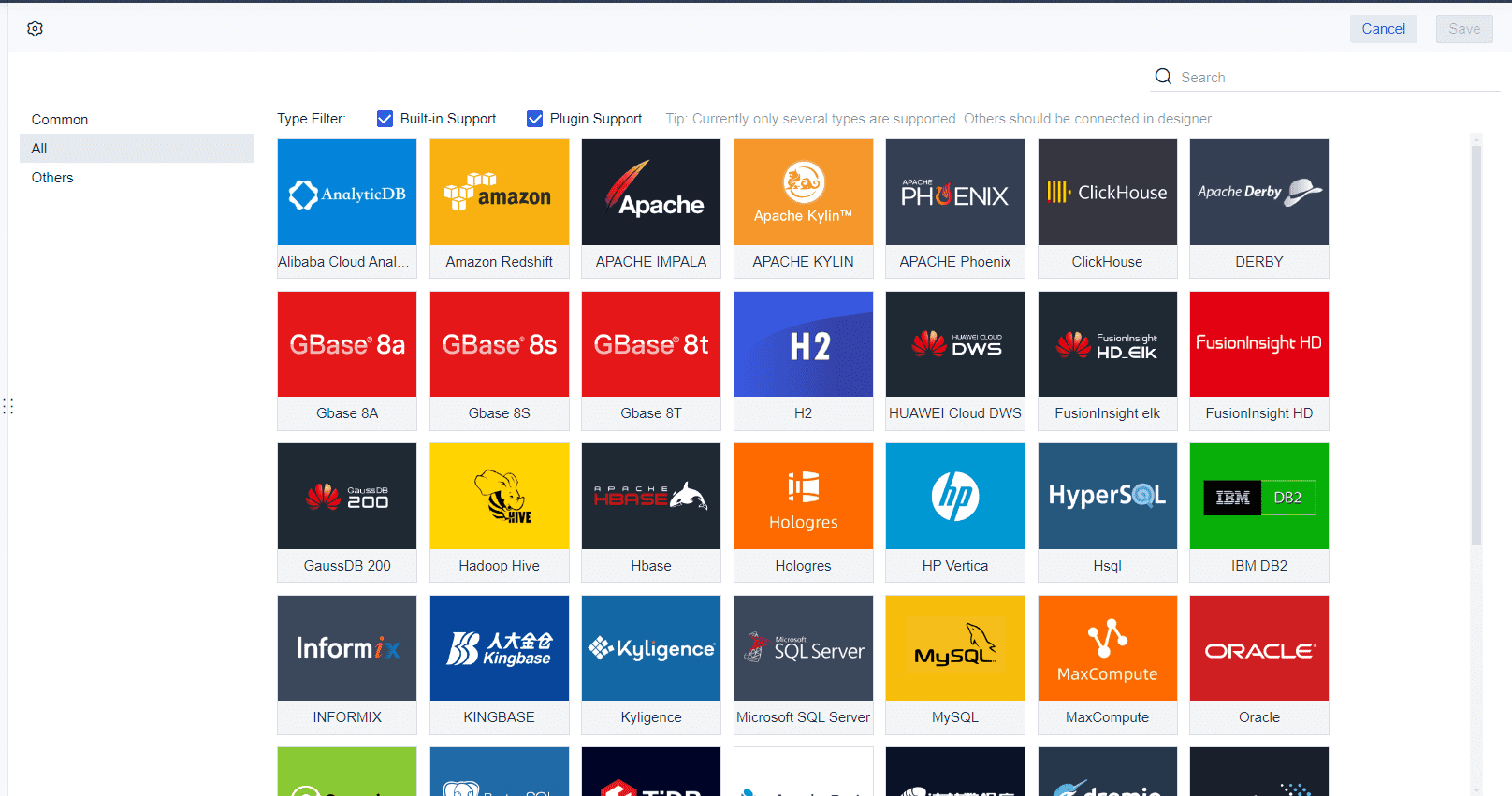

You need a strong data integration platform to unlock the full power of your digital factory. In a smart factory, you collect data from machines, sensors, and business systems. Platforms like FineReport and FineVis help you bring all this information together. They connect your production lines, supply chain, and quality systems, giving you a single view of your operations. This unified approach supports real-time decision-making and helps you spot trends or problems quickly.

Many leading platforms, such as Siemens Opcenter Execution, dataPARC, and TIBCO Cloud Integration, focus on connecting MES, ERP, and other systems. These platforms let you track production, monitor machine efficiency, and manage supply chain risks. FineReport and FineVis stand out by offering easy integration, real-time analytics, and powerful visualization tools. You can use these tools to analyze data, create dashboards, and share insights across your digital factory.

| Platform Name | Integration Focus |

|---|---|

| Siemens Opcenter | MES, ERP, LIMS, QMS, SCADA |

| dataPARC | Machines, MES, ERP, lab, quality systems |

| TIBCO Cloud Integration | Business apps, data, devices, hybrid environments |

| FineReport/FineVis | Unified data, real-time analytics, visualization |

Data integration platforms act as the backbone of your smart factory, supporting intelligent automation and real-time insights.

The internet of things and industrial IoT connect your machines and devices, allowing you to collect real-time data from every corner of your digital factory. IoT sensors track equipment health, energy use, and product quality. AI analyzes this data to predict failures, optimize production, and improve safety. Automation and robotics handle repetitive tasks, boost productivity, and reduce errors.

You see these technologies working together in many ways:

Companies like Honeywell and Tesla use AI, IoT, and automation to improve efficiency and quality. You can do the same in your digital factory by combining these technologies for smarter, faster operations.

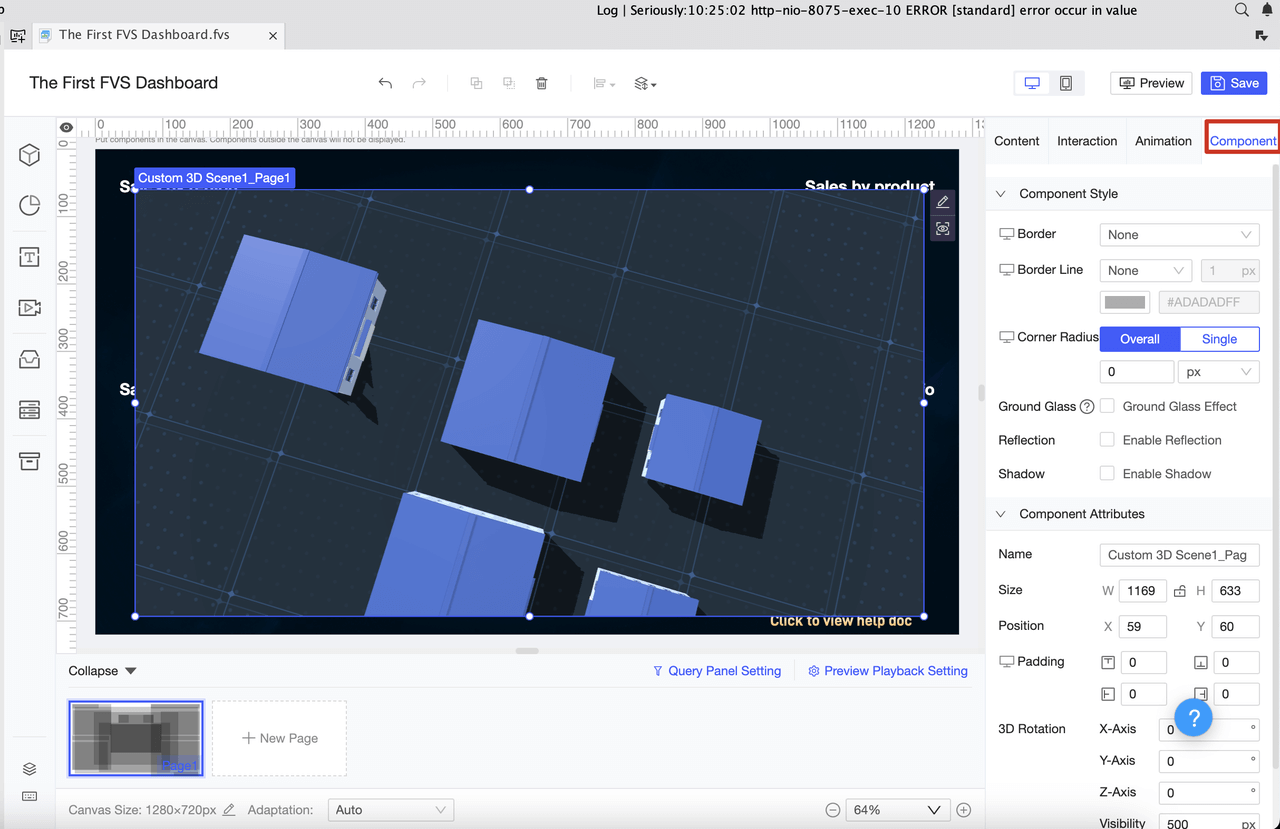

Real-time analytics give you instant feedback on your digital factory’s performance. FineReport and FineVis help you visualize data from IoT devices, AI models, and automation systems. You can see trends, spot bottlenecks, and make quick decisions. Real-time dashboards show you key metrics like machine uptime, energy use, and product quality.

This approach brings many benefits:

Over 80% of manufacturers use real-time analytics to boost productivity and reduce costs. With the right tools, you can transform your smart factory into a truly intelligent operation.

You need a smart factory solution that brings all your systems together. This means connecting your MES (Manufacturing Execution System), QMS (Quality Management System), ERP (Enterprise Resource Planning), and SCM (Supply Chain Management). When you integrate these systems, you create a single, unified platform for your manufacturing process. This integration lets you manage everything from production planning to quality checks and logistics in one place.

To achieve successful integration, you should follow these best practices:

When you integrate your systems, you break down data silos and enable seamless communication across your factory. This unified approach supports reliable, bidirectional data flow and helps you automate your manufacturing process.

A smart factory solution like FanRuan supports this integration at every level. You can connect field sensors, PLCs, SCADA, MES, and ERP systems. This layered approach ensures that data flows smoothly from the shop floor to the executive office. You gain unified control and automation, which boosts productivity and innovation.

You need accurate, real-time data to run a smart factory. A smart factory solution uses IoT sensors and devices to collect data from machines, equipment, and even the environment. These sensors track parameters like temperature, vibration, speed, and pressure. You can use this data to monitor your manufacturing process, spot problems early, and keep your operations running smoothly.

There are several methods for data collection and monitoring:

Platforms like FanRuan’s FineReport and FineVis help you collect, visualize, and analyze this data. You can use over 300 communication protocols to connect different equipment and systems. Real-time dashboards show you what’s happening on the factory floor. You can see machine status, production rates, and quality metrics at a glance.

Real-time monitoring gives you instant feedback. You can detect deviations, trigger alerts, and take corrective action right away. This reduces downtime and improves product quality.

Smart factory solutions also use AI-powered vision systems and inspection tools. These tools check product quality during production, not just at the end. You can catch defects early and prevent waste. Predictive maintenance becomes possible because you can spot equipment issues before they cause breakdowns.

A smart factory solution does more than just collect data. It uses AI, machine learning, and automation to make decisions on its own. You can let your systems analyze data, predict problems, and even take action without waiting for human input.

Key technologies that enable autonomous decision-making include:

With these technologies, your smart factory can:

When you use a smart factory solution with advanced AI, you empower your factory to operate with minimal human intervention. Your systems can monitor, analyze, and optimize the manufacturing process continuously.

FanRuan’s smart factory solution leverages real-time data, AI-driven analytics, and automation to support autonomous decision-making. You can trust your factory to maintain high efficiency, quality, and flexibility, even as demands change.

You can achieve remarkable improvements in efficiency and cost savings when you adopt smart factory solutions. These systems help you monitor every machine, optimize resource allocation, and reduce unnecessary shifts. Real-time dashboards let you spot inefficiencies and take immediate action. Automation handles repetitive tasks, freeing your team to focus on higher-value work and boosting productivity.

FanRuan’s FineReport and FineVis platforms support these gains by providing real-time analytics and visual dashboards. You can track performance, identify root causes, and make data-driven decisions that improve profit margins.

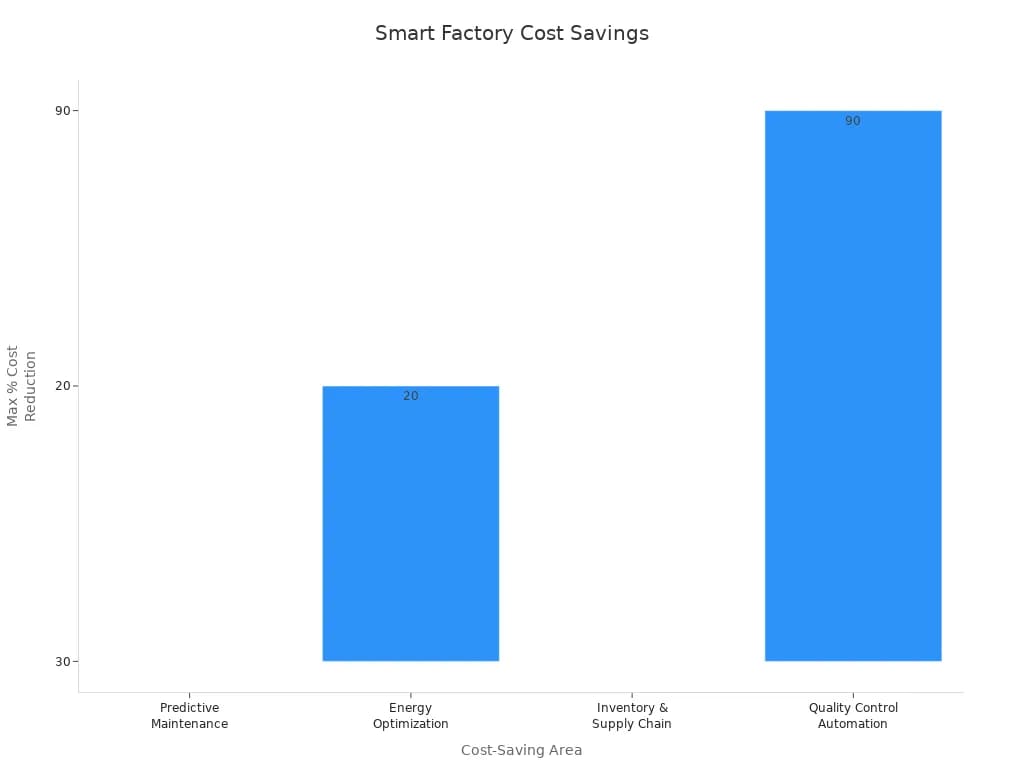

| Cost-Saving Area | Impact/Benefit | Real-World Example |

|---|---|---|

| Predictive Maintenance | Up to 30% reduction in maintenance costs; 70% fewer breakdowns; 25–30% increase in uptime | General Motors saved over $40 million annually by implementing PdM across 100+ facilities |

| Energy Optimization | 10–20% reduction in energy costs; better sustainability compliance | Schneider Electric helped a food plant reduce energy use by 15% using IoT and automation |

| Inventory & Supply Chain | 20–30% reduction in inventory holding costs; fewer stockouts and overstocking | Bosch reduced excess stock by 25% and improved order fulfillment using AI and digital twins |

| Quality Control Automation | Up to 90% reduction in inspection time; fewer recalls and rework costs | BMW uses AI image recognition for weld and paint inspection, saving millions annually |

Smart factory solutions help you cut costs and increase productivity, giving your business a competitive edge.

You gain full visibility into your operations with smart factory solutions. Real-time data sharing eliminates silos and supports quick decision-making. Automation and advanced analytics uncover patterns, enabling predictive maintenance and real-time quality control. You can adjust production schedules instantly, reduce lead times, and deliver products faster.

FanRuan’s platforms empower you to monitor production, analyze trends, and optimize processes. You see improvements in delivery performance and customer satisfaction, while your team focuses on innovation and continuous improvement.

Smart factories boost agility and quality, allowing you to meet customer needs and stay ahead in a fast-changing market.

Smart factory solutions support your sustainability goals by optimizing resource use and reducing emissions. You can monitor energy consumption, track pollutant emissions, and automate machine dormancy to save energy. AI and IoT technologies help you minimize waste and extend equipment lifespan.

FanRuan’s FineReport and FineVis help you visualize sustainability metrics and make informed decisions. You create a greener, more efficient factory that meets regulatory standards and supports long-term growth.

By adopting smart factory solutions, you contribute to a healthier planet and build a more resilient business.

You start your smart factory journey by building a digital office. This means you move away from paper records and manual processes. You collect and store data in digital form. You connect your teams with digital tools for communication and collaboration. This step helps you share information quickly and keep everyone on the same page.

To set up a digital office, follow these steps:

A digital office lays the foundation for more advanced smart factory practices. It helps you manage data, improve teamwork, and prepare for automation.

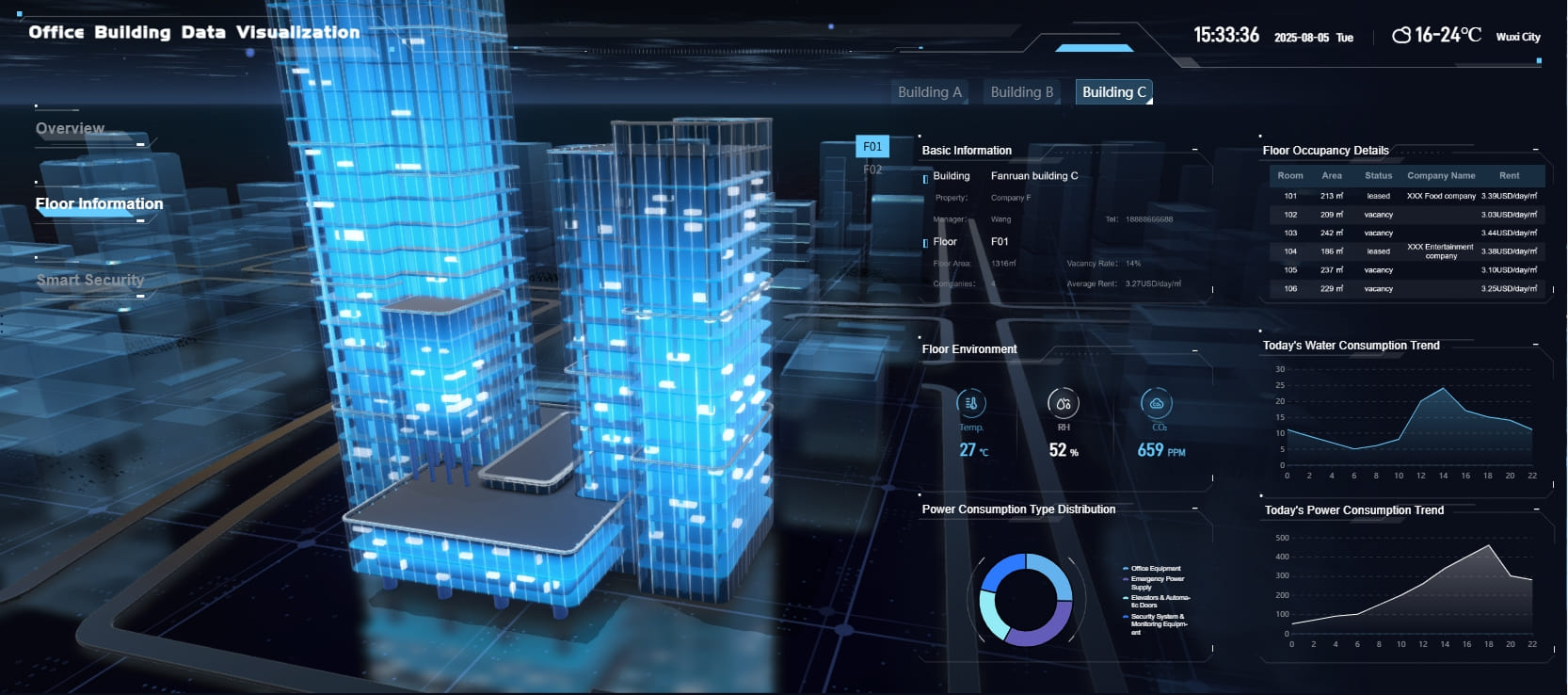

FanRuan offers a powerful platform to help you manage your smart factory. The FanRuan Smart Factory Operation and Control Platform connects your machines, sensors, and business systems. You get real-time data from every part of your factory. You can monitor production, track equipment health, and analyze performance on interactive dashboards.

This platform supports you through every stage of your smart factory journey:

FanRuan provides ongoing support, training, and updates. You can rely on their expertise to ensure a successful deployment and continuous improvement.

Tip: Involve your employees early and provide training to help them adapt to new technologies.

Smart factories need strong supply chain control. You use IoT sensors to track goods in real time. GPS and condition sensors show you where your products are and if they stay safe during transport. This visibility helps you reduce losses and improve product quality.

You also benefit from:

Companies that use these methods see fewer disruptions, lower storage costs, and higher customer satisfaction. FanRuan’s solutions help you map your supply chain, monitor supplier performance, and ensure transparency from production to delivery.

Smart factory solutions have changed manufacturing into a digital-first, data-driven environment. You gain more than efficiency. You build a future-ready business.

Explore FanRuan, FineReport, and FineVis to start your smart factory journey. Begin with small steps and scale as you grow.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025