Smart manufacturing uses connected devices, automation, and data management to improve how you run your factory. You can see its impact worldwide—84% of manufacturers now use or evaluate smart manufacturing, with China leading at 70%.

Digital transformation drives this shift, bringing real-time data management and analytics. When you adopt smart manufacturing, you unlock higher production output, better employee productivity, and reduced equipment downtime. Solutions like FanRuan and FineReport help you integrate data management, support transformation, and enable smarter decisions every day.

All templates in this article were created by FineReport.

You can think of smart manufacturing as a new way to run factories. It connects people, machines, and digital systems so they work together in real time. You use advanced technologies like artificial intelligence, sensors, and cloud computing to collect and analyze data from every part of your production line. This approach helps you make better decisions, respond quickly to changes, and keep your operations running smoothly.

Industry experts say smart manufacturing means you combine technology and process integration. You bring together AI, sensor technologies, and digital twins with your manufacturing processes. This integration lets your machines and operators share resources, trigger maintenance, and optimize production as a team. You also support asset management and quality assurance by using remote servicing and real-time monitoring. Digital twins allow you to test and simulate before you build anything, which saves money and reduces risk.

Smart manufacturing is a key part of industry 4.0. It creates fully integrated, collaborative systems that react instantly to new demands or problems. You blend human creativity with connected machines, AI-powered analytics, and cloud-based data management. This combination helps you improve quality, boost efficiency, and customize products for your customers.

Smart manufacturing is not just about having the latest machines. It is about using data management to connect everything in your factory, so you can make fast, informed decisions.

You will notice several important ideas that set smart manufacturing apart from traditional methods. Here are the main concepts you should know:

Here is a table that summarizes the principles of smart manufacturing:

| Principle/Aspect | Description |

|---|---|

| Integration of People, Processes, and Technology | You create a synergy between your team, your processes, and your technology. Everything works together in a secure, scalable, and proactive way. |

| Connectivity & Interoperability | You enable communication across devices, systems, and partners using open standards and APIs. |

| Real-time & Flat Information Flow | You digitally integrate resources and monitor them continuously for fast, event-driven decisions. |

| Automation & Proactivity | Your systems adapt quickly to changes with minimal help from you. |

| Security | You ensure data integrity, protect intellectual property, and keep your business running smoothly. |

| Scalability | Your systems grow with your needs and can be adopted by suppliers of any size. |

| Sustainability | You optimize resources and energy, reduce environmental impact, and support recycling. |

You will see that smart manufacturing uses automation, data management, and advanced analytics to create a flexible, efficient, and connected production environment. Unlike traditional manufacturing, you do not rely on manual labor or linear processes. Instead, you use real-time data management to make decisions, predict problems, and keep your factory running at its best.

Tip: When you focus on data management in smart manufacturing, you gain better visibility, faster response times, and higher product quality.

You want your factory to run faster, make fewer mistakes, and deliver better products. Smart manufacturing helps you reach these goals by using data management at every step. When you collect and analyze data from machines, you spot problems early and fix them before they slow you down. You can use dashboards and notifications to keep track of performance in real time.

Here are some real-world results that show how smart manufacturing boosts efficiency:

You can also use robotics to automate repetitive or dangerous tasks. This increases speed and accuracy, which means higher product quality. Cloud and edge computing let you monitor data in real time, so you make decisions quickly and keep your operations reliable. Digital twins give you a virtual copy of your equipment, helping you detect issues and optimize processes.

NIST research shows that new production technologies drive big improvements in manufacturing efficiency. Overcoming barriers to adopting these tools can help you gain even more benefits across your supply chain.

Smart manufacturing also improves quality. You can upgrade your existing robots with better control systems and advanced algorithms. This makes their movements smoother and more stable, which leads to fewer defects. Real-time monitoring and data analytics help you adjust critical variables during production. AI and machine learning spot patterns and predict when equipment needs maintenance, so you avoid breakdowns and keep quality high.

You can see that data management is the backbone of these improvements. By tracking every detail, you reduce errors, prevent waste, and deliver products that meet high standards.

Staying ahead in the market means you must adapt quickly and make smart choices. Smart manufacturing gives you the tools to do this. You use data management to connect every part of your operation, from the shop floor to the supply chain. This end-to-end visibility helps you respond fast to changes in demand or supply.

You can use real-time data to spot trends, predict problems, and adjust your production plans. Automation frees your team from routine tasks, so they can focus on solving bigger challenges. Advanced analytics help you find patterns in large data sets, making your decisions more accurate.

Smart manufacturing is not just about keeping up. It is about building resilience and agility, so you can handle market shifts and customer needs with confidence.

Agile manufacturing lets you customize products and manage risks better. You can quickly change your production lines to meet new requirements. Integration with ERP systems ties all your data together, giving you the transparency you need to act fast. Your team can collaborate in real time, making adjustments and improvements as needed.

With strong data management, you build a digital foundation that supports innovation and keeps you ahead of the competition.

You want your factory to be efficient and also good for the environment. Smart manufacturing helps you achieve both. By using data management, you track energy use, emissions, and resource consumption in real time. This lets you find ways to save energy, reduce waste, and lower your carbon footprint.

Smart manufacturing uses IoT, AI, and data analytics to optimize every process. Predictive maintenance can cut maintenance time by up to 50% and increase equipment uptime by 20%. Additive manufacturing and robotics reduce material waste and energy use. Companies like LG Electronics and Procter & Gamble have used digital twins to cut energy use and inventory by about 30%.

| Company | Technologies Used | Contribution to Resource Efficiency and Waste Reduction |

|---|---|---|

| General Electric | IoT sensors, AI-powered predictive maintenance | Improved resource efficiency by reducing downtime and waste |

| Siemens | Data analytics, machine learning algorithms | Optimized production planning, leading to reduced waste and better resource use |

| Daimler | IoT sensors, AI-powered quality control | Enhanced product quality and reduced waste through anomaly detection and automation |

You can use real-time monitoring to spot inefficiencies and fix them quickly. Automation and robotics help you avoid human error and improve quality control. Flexible production lets you adapt to demand changes, so you do not overproduce or waste resources.

Continuous monitoring of key performance indicators like energy use, emissions, and waste is essential for ongoing improvement. Smart manufacturing supports your sustainability goals and helps you meet regulatory demands.

By making data management a core part of your strategy, you not only improve your bottom line but also support a healthier planet.

Smart manufacturing technologies rely on several core innovations that help you transform your factory into a connected, efficient, and intelligent environment. You use these tools to collect, manage, and analyze data, making your manufacturing processes smarter and more responsive.

The internet of things (IoT) connects machines, sensors, and controls across your factory. You see real-time data flow between devices, which lets you adjust operations instantly. IoT sensors monitor machine health, temperature, vibration, and wear, sending alerts before breakdowns happen. You use RFID tags and smart cameras for live inventory tracking and quality control. IoT wearables improve worker safety by monitoring health and location. Industrial IoT gateways and edge computing devices help you automate repetitive tasks and optimize energy use. Digital twins powered by IoT sensors create virtual models for simulation and process optimization. Research shows that using industrial IoT and deep learning can boost production efficiency by at least four percentage points.

Tip: IoT enables seamless communication and proactive decision-making, turning your factory into a flexible, automated, and intelligent environment.

Artificial intelligence (AI) helps you predict equipment failures and optimize manufacturing processes. AI-driven predictive maintenance analyzes sensor data to forecast problems before they occur. You use AI-powered control systems to adapt production parameters in real time, improving quality and flexibility. AI-based analytics uncover hidden patterns and optimization opportunities. Machine vision systems powered by AI detect defects with superhuman accuracy, reducing waste. Generative AI automates programming for robots, speeding up manual tasks. Industry surveys show that 95% of manufacturers invest in AI, with top performers seeing a 25% reduction in downtime and a 15% increase in throughput.

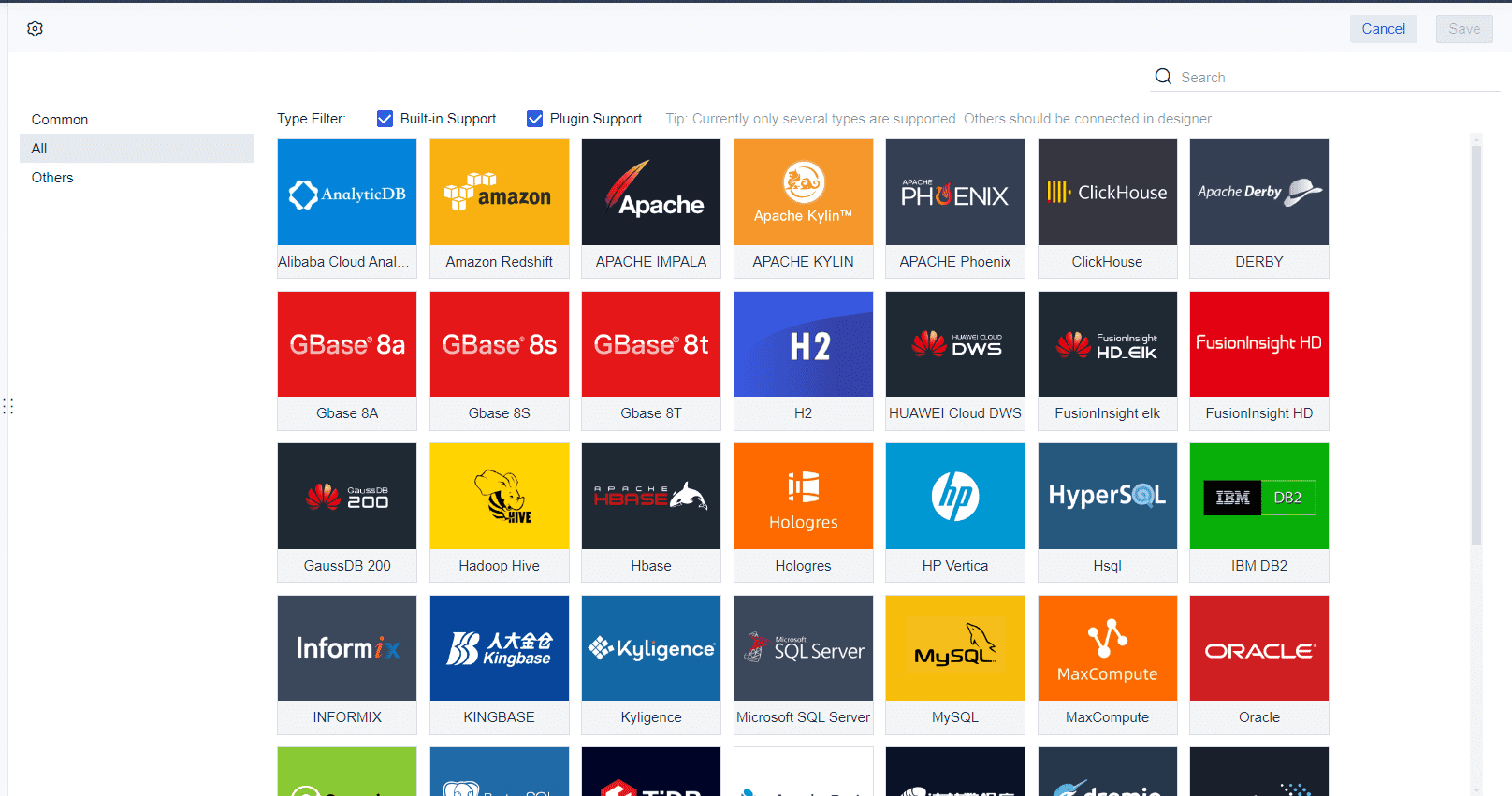

Data analytics gives you the power to make smarter decisions and improve operational efficiency. You integrate systems like ERP and CRM to streamline workflows and track demand. Predictive analytics help you anticipate equipment maintenance needs, reducing downtime. Visualization tools let you spot trends and patterns, making it easier to act quickly. Advanced analytics identify bottlenecks and optimize production schedules. You use data management platforms like FanRuan and FineReport to connect diverse data sources, automate reporting, and monitor performance in real time. These tools support smarter decisions, higher productivity, and cost savings.

| Category | Examples/Tools/Technologies | Purpose/Role in Smart Manufacturing |

|---|---|---|

| Machine Learning Libraries | TensorFlow, PyTorch | Building predictive models |

| Data Science Platforms | Jupyter Notebooks, RStudio | Collaborative analytics development |

| Analytics Software | Tableau, Power BI | Visualization and reporting |

| Data Collection Technologies | IIoT devices, sensors | Real-time data collection |

| Data Storage | Data historians | Centralized time-series data management |

| Data Integration Platforms | FanRuan, FineReport | Integration of diverse manufacturing data |

| Cloud-based Platforms | Cloud infrastructure | Scalable, secure data storage and processing |

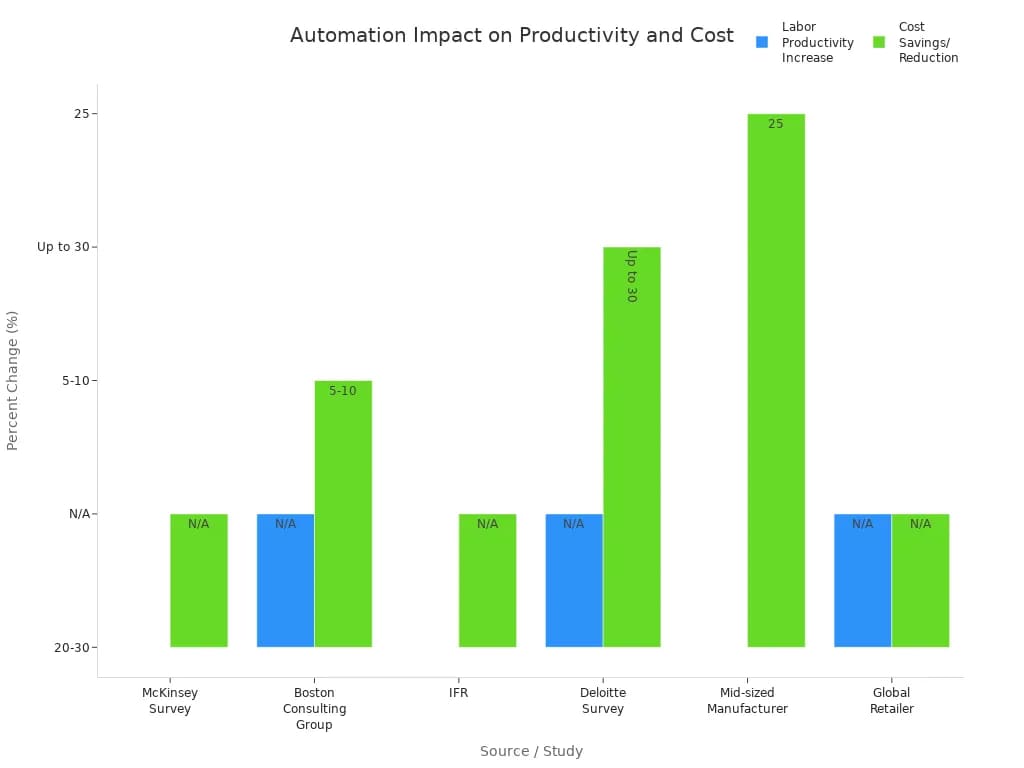

Automation lets you boost productivity and cut costs. You use robots and automated systems to handle repetitive tasks, reducing human error and improving quality. Collaborative robots (cobots) work alongside your team, increasing labor productivity by up to 30%. Automated scheduling systems save time and lower administrative costs. AI-powered automation reduces manual data processing, freeing your workers for higher-value roles. Studies show that automation can lead to a 20-30% increase in productivity and a 25% reduction in operational costs. FanRuan and FineReport support automation by integrating data management, enabling real-time monitoring, and automating reporting and analytics.

Digital transformation changes how you run your factory. You use advanced digital technologies to connect machines, people, and systems. This approach helps you build smart factories that respond quickly to changes and improve efficiency.

You need strong data integration to succeed with digital transformation. You collect data from sensors, IoT devices, and business systems. You use integration platforms to combine data from different sources, such as ERP, inventory, and supply chain systems. This unified data management lets you monitor production, track equipment, and analyze quality in real time.

| Manufacturer | Integration Approach | Benefits Achieved |

|---|---|---|

| BMW | Sensors and IoT devices collect real-time data on machine performance and quality. | Higher productivity, reduced downtime, improved product quality. |

| Siemens | Advanced analytics and AI process real-time data from production lines. | Optimized processes, streamlined workflows, improved quality control. |

| Foxconn | IoT sensors and real-time analytics monitor machine performance and logistics. | Increased efficiency, reduced costs, improved product quality. |

You see that data management helps you break down silos and automate workflows. You gain supply chain visibility and improve safety by identifying hazards early.

Tip: Choose tools that support real-time data processing and ensure compatibility with your existing systems.

Real-time insights give you instant visibility into your operations. You use data management to detect problems as they happen, not after the fact. Real-time analytics help you balance workloads, optimize schedules, and reduce waste. You can spot defects immediately and take action to protect your brand.

You rely on data management to make faster decisions and keep your smart factories running smoothly.

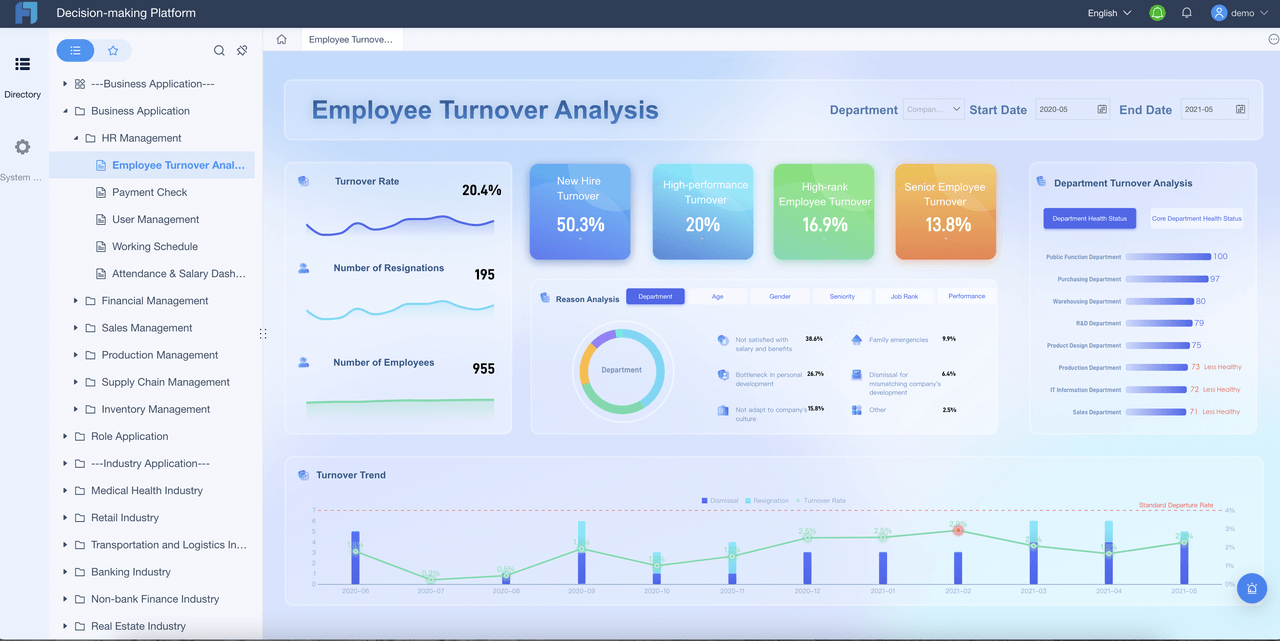

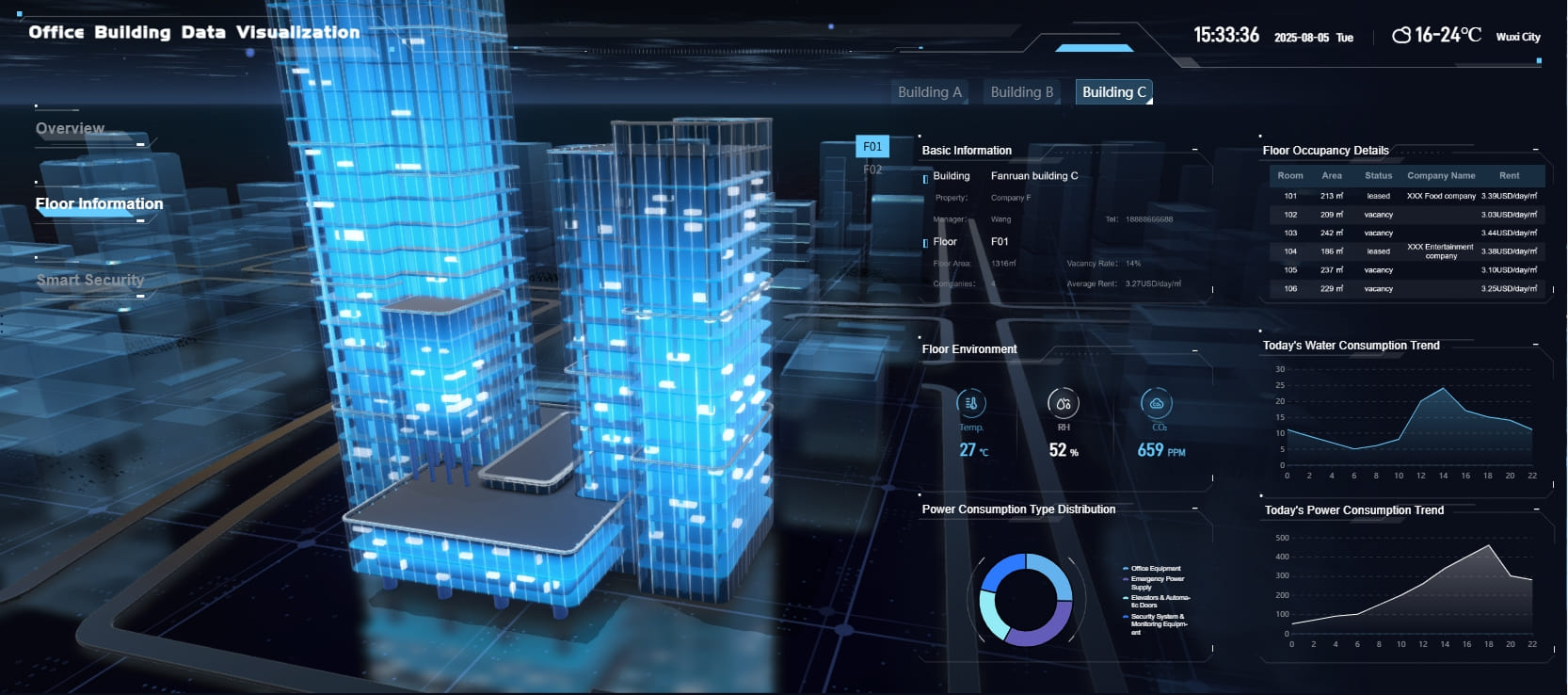

FineReport supports your digital transformation by making data integration and analytics easy. You connect to multiple data sources and create interactive reports with a drag-and-drop designer. FineReport centralizes your business data, so you can analyze and visualize it from any device. You use real-time dashboards to monitor production, equipment, and quality metrics.

FineReport helps you manage data from smart factories, equipment management, and intelligent inspection solutions. You automate reporting, schedule tasks, and share insights across your team. With FineReport, you build a strong data management foundation for your transformation journey.

Note: Digital transformation empowers you to use data management for better decisions, higher efficiency, and smarter factories.

You can start your smart manufacturing journey by following a clear set of steps. First, align your technology choices with your business needs. Identify the main challenges in your factory and select the right smart manufacturing technologies. Next, assess your current infrastructure. Check if your hardware, software, and network can support new systems. Involve your team from IT, operations, and supply chain. Provide training so everyone understands the new tools.

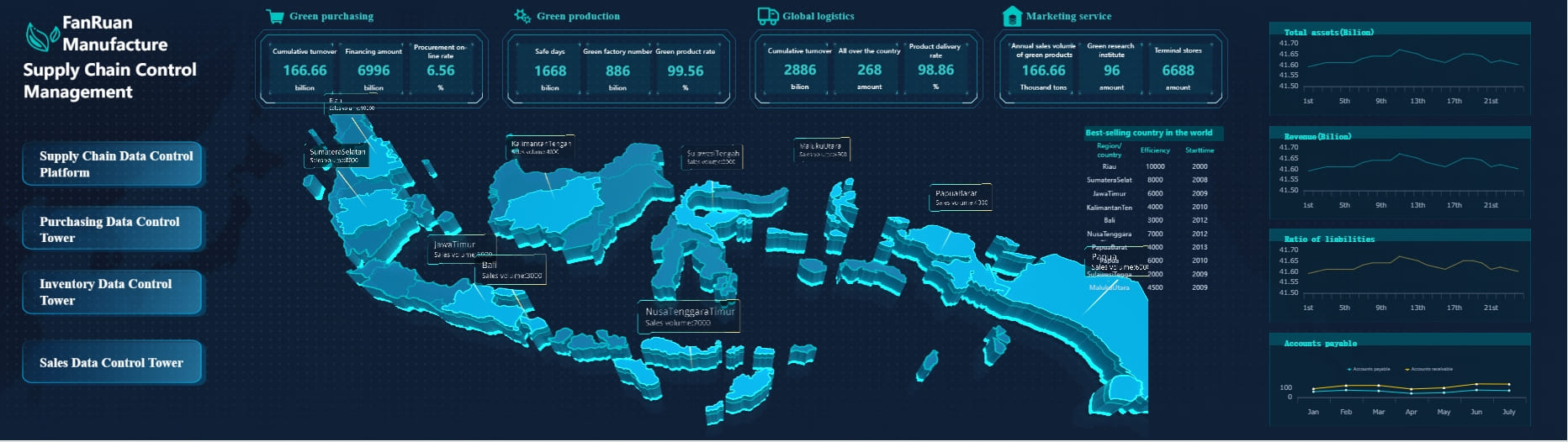

Develop a detailed roadmap. Set clear goals, timelines, and budgets. Bring in experts or partners if you need new skills. Monitor your progress by tracking key performance metrics. Adjust your processes as you learn. FanRuan’s Smart Factory Operation and Control Platform helps you integrate data from machines, sensors, and business systems. You can use FineReport to connect all your data sources, automate reporting, and create real-time dashboards. This strong data management foundation lets you make better decisions and respond quickly to changes.

A digital office supports your smart manufacturing goals by making data management easy for everyone. You can collect, store, and share data across departments. FineReport allows you to design custom reports and dashboards with a simple drag-and-drop interface. You can access your data from any device, which helps you monitor production, track equipment, and analyze quality in real time. Automated data management reduces manual work and errors. You can schedule reports and share insights with your team, making collaboration smooth and efficient.

Smart manufacturing improves your supply chain by giving you real-time visibility into every step. You can use data management to track orders, inventory, and shipments. FineReport helps you integrate data from ERP, MES, and WMS systems. You can monitor supply chain performance with live dashboards and alerts. This approach helps you spot problems early and adjust your plans quickly. Data management ensures that you have accurate, up-to-date information for every decision.

Tip: Start with small pilot projects to test your smart manufacturing solutions. Use data management to measure results and scale up when you see success.

A strong focus on data management and workforce training will help you succeed with smart manufacturing. You build a culture of innovation and continuous improvement.

Smart manufacturing transforms how you work by boosting efficiency, quality, and competitiveness. You gain real-time insights, automate tasks, and make better decisions with tools like FanRuan and FineReport. As you look ahead, expect these trends to shape the future:

Embrace these changes to stay ahead and build a smarter, more resilient factory.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025