Product data management software helps you organize, control, and share all your product data in one place. You can manage important files such as:

Centralizing product data means you always know where to find the latest models, drawings, and specifications. The table below shows more examples of what you can manage with pdm:

| Product Data Types | Description / Examples |

|---|---|

| Product Models | 3D models, CAD files |

| Specifications | Technical details and product requirements |

| Drawings | Engineering drawings, blueprints |

| Engineering Change Orders | Documentation of product design changes |

| Bills of Materials (BOM) | Lists of components and materials |

| Product Parts Information | Details about individual parts |

| Manufacturing Instructions | Guidelines for production processes |

| Design Revisions | Tracking changes and iterations in product design |

| Product Documentation | Manuals, datasheets, and related documents |

| Metadata | Data ownership, release status, indexing |

You need strong product data management software to keep your team efficient. In manufacturing or any data-driven company, pdm ensures everyone works with the right product data at every step.

All dashboards in this article are created with the self-service analytics tool FineBI. Click the button below to try FineBI for free and start your self-service analytics journey!

You use product data management software to organize, track, and control all the information related to your products. According to leading industry sources, this type of software acts as a central knowledge base for your company. It stores technical specifications, manufacturing details, and development data. You can think of it as a digital filing cabinet that helps you and your team find the right files, drawings, and documents whenever you need them.

Product data management software supports collaboration between engineers, project managers, and sales teams. It manages engineering data such as CAD models and drawings. It also controls versioning and the release of product components. Most companies use product data management software during the design and engineering phases, but it also serves as the foundation for broader product lifecycle management.

Tip: When you use product data management software, you create a single source of truth for your product data. This reduces errors and makes sure everyone works with the latest information.

A product data management software handles many types of product data. You can store and manage everything from design files to manufacturing instructions. Here are some common categories:

| Category | Description/Role in PDM System |

|---|---|

| Bills of Material | Lists components and subassemblies required for products |

| Routings | Defines the sequence of operations for manufacturing |

| Work Centers | Specifies locations or machines where operations occur |

| Engineering Change Management | Manages updates and revisions to product data and processes |

You also manage other important product data, such as:

When you centralize all this product data in a pdm software, you break down data silos. This means your teams can access real-time, consistent information. You improve decision-making, product traceability, and compliance with regulations. Centralized data management also helps you reduce errors and streamline your operations.

Product data management software offers several core functions that help you manage your product data efficiently. Here are the main features you will find in most pdm software:

Note: Essential features for enterprise use include robust security, advanced search, revision control, automatic part numbering, and real-time analytics. These features help you maintain control over your product data as your business grows.

When you use product data management software, you standardize data formats and terminology. You also automate validation and approval chains. This improves governance and supports compliance. By reducing errors and streamlining workflows, pdm software helps you bring products to market faster and with fewer mistakes.

Product Data Management Software helps you organize and control your product data from the start of a project to the final release. You follow a clear workflow to make sure your team always works with accurate and up-to-date information. Here is a typical workflow you might use when setting up and running a pdm software in a manufacturing environment:

Tip: Automating workflows in your product data management software saves time and reduces mistakes. You can set up approval processes, assign tasks, and track progress in real time.

A pdm software automates many tasks for you. It can:

You can also use the system to detect data issues and alert the right people. This helps you fix problems quickly and keep your product data reliable.

A strong product data management software connects with the other tools you use every day. You can link your pdm software to:

These integrations help you centralize your product data, improve version control, and support smooth product development. You break down data silos and make sure everyone works with the same information.

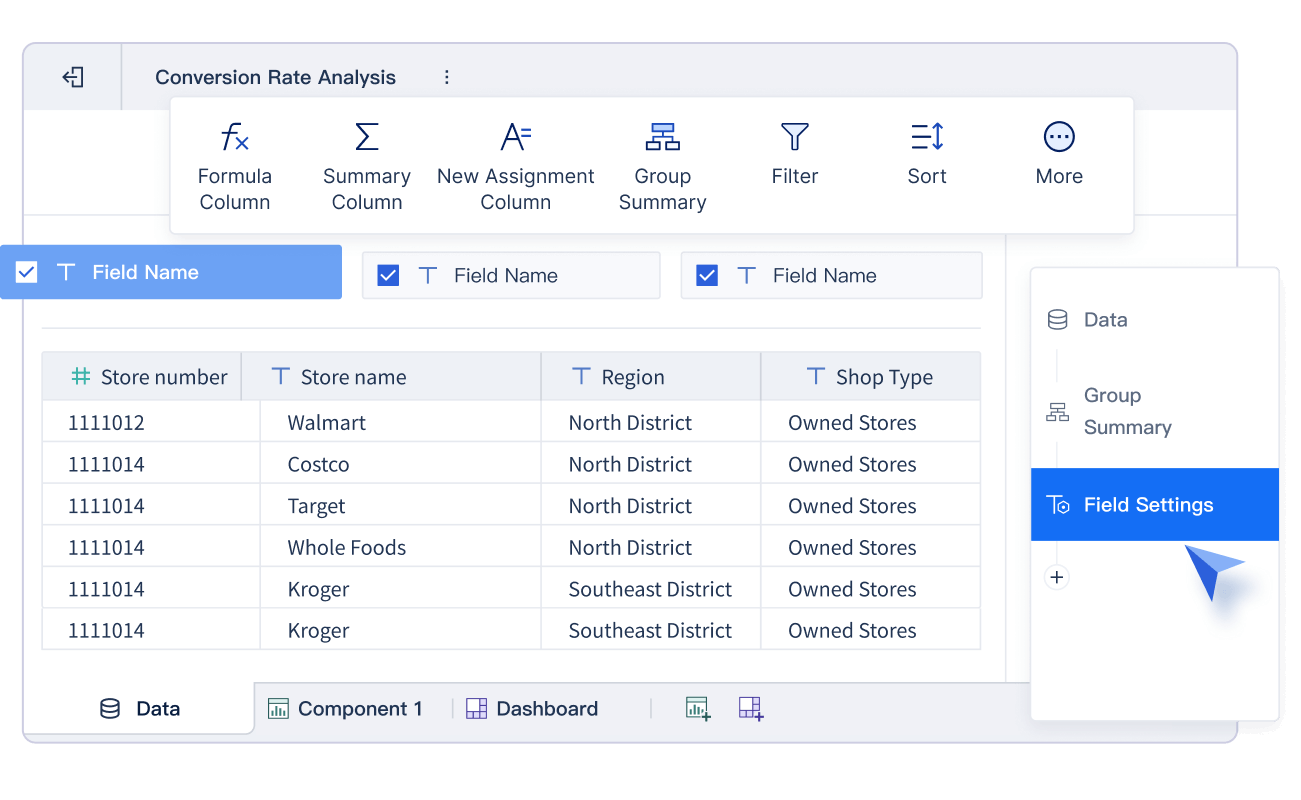

FineBI give you powerful integration and data management features for manufacturing and enterprise environments. With FineBI, you can:

FineBI supports real-time analytics an5d unified data management. You can handle large volumes of product data, automate reporting, and ensure secure access for your team. These features help you keep your product data accurate, up-to-date, and ready for analysis.

Note: When you integrate your product data management software with business tools, you improve efficiency, reduce manual work, and support better collaboration across departments.

You gain significant efficiency when you use product data management software. The system gives you a single source of truth for all your product data. This reduces errors and helps your team avoid working with outdated files. You can automate validation and approval processes, which speeds up your workflow and improves product quality.

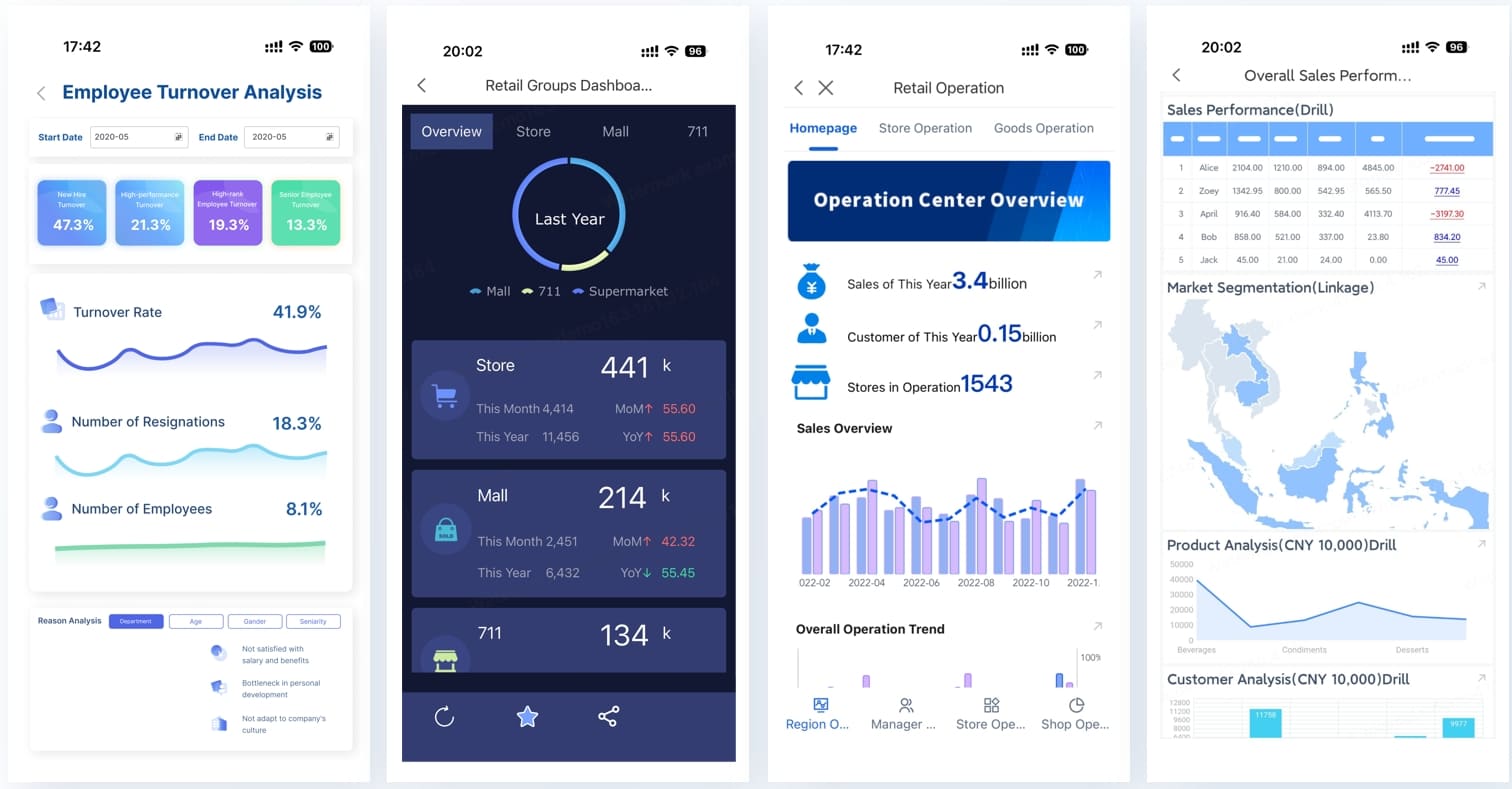

When you use FineBI from FanRuan, you connect your product data to real-time dashboards. You can track production metrics, monitor changes, and collaborate with your team in one place. For example, a manufacturing company used FineBI to centralize product data, which helped them cut development time and improve communication between engineering and production teams.

Accurate product data is essential for your business. Product data management software helps you keep your information clean and reliable. You can automate data validation and cleaning, which reduces errors in your supply chain. Companies like Kmart Australia and Saint-Gobain improved their data accuracy by centralizing product data and automating updates. This led to faster product launches and fewer costly returns.

FineBI solutions also keep your product data secure. You control access with role-based permissions and secure authentication. You can share dashboards safely and protect sensitive data on mobile devices. FineBI’s robust architecture ensures your product data stays available and protected, even during system failures.

With strong data management, you build trust with your customers and partners. You also gain resilience and cost savings by using accurate product data for supplier and distributor management.

You may wonder how product data management and product information management differ. Both systems help you organize product-related data, but they serve different purposes and users. The table below highlights the main differences:

| Aspect | Product Data Management (PDM) | Product Information Management (PIM) |

|---|---|---|

| Primary Focus | Managing technical and engineering data (CAD drawings, BOMs) | Consolidating and managing product information for marketing and sales |

| Origin | CAD industry | Business practices for marketing and sales |

| Typical Users | Engineers, operations teams | Sales, marketing, commerce teams |

| Data Managed | Technical specs, version control, engineering models | Product descriptions, pricing, SKUs, digital assets |

| Purpose | Support design, production, manufacturing processes | Ensure consistent product info delivery across channels |

| Scope | Technical and engineering-centric | Broader, including sales and marketing needs |

| Business Impact | Product lifecycle and manufacturing efficiency | Essential for eCommerce and omnichannel strategies |

You use product data management to control technical files, engineering models, and design changes. This system supports your product lifecycle management and manufacturing processes. On the other hand, pim helps you manage product information like SKUs, pricing, and descriptions. It ensures your product information stays consistent across websites, catalogs, and sales channels. While pdm focuses on engineering, pim supports marketing and sales.

Note: Industry analysts say that pim systems collect, enrich, and manage product information in one place. This helps you deliver accurate product information to customers, no matter where they shop.

You choose product data management when you need to handle technical data, engineering drawings, and version control. This system fits best in manufacturing, engineering, and plm environments. You rely on pdm to support collaboration between engineers and to keep your product data accurate during design and production.

You turn to pim when your goal is to manage product information for marketing, sales, and eCommerce. This system works well in retail, distribution, and any business that sells products across multiple channels. pim lets you create rich product content, manage digital assets, and ensure your product information reaches customers everywhere.

You often see both systems working together. For example, you might use pdm to manage technical data and then send approved product information to pim for marketing and sales. This combination gives you full control over your product lifecycle management and customer experience.

Tip: Integrating pdm and pim with your plm system helps you deliver a complete product experience, from design to customer delivery.

When you choose a product data management software, you need to check if it works well with your current tools and can grow with your business. Many companies face compatibility challenges, especially when they use older IT systems. You might see issues like:

To avoid these problems, you should test the system with real data and workflows before going live. Make sure you check how the system handles data from different sources, including pim and other business tools. Leading systems use cloud-based platforms to connect production planning, inventory, and supply chain data. They also support advanced technologies like AI, IoT, and automation. This helps you scale up as your business grows and keeps your product data and pim information accurate and up to date.

Security is a top priority when you manage product data. Enterprise-grade systems offer features such as:

You should also check if the system fits your industry needs. Start by looking at your current processes. Are you spending too much time on manual tasks or fixing errors in product data or pim content? Use a table to guide your assessment:

| Step | Description | Purpose |

|---|---|---|

| Define Scope and Objectives | Set clear goals for data management | Focus your evaluation |

| Build a Cross-Functional Team | Include IT, finance, and operations | Ensure balanced input |

| Evaluate Current Practices | Review how you handle product and pim data | Find gaps and improve |

| Review Existing Tools | Check if current systems meet your needs | Identify upgrade opportunities |

By following these steps, you can choose a system that keeps your data secure, supports your growth, and works well with pim and other business tools.

Product data management software gives you better control, accuracy, and collaboration across your organization. You streamline compliance, improve customer experience, and boost innovation by treating data as a valuable asset.

Evaluate your current processes using these key metrics:

| Metric | Description |

|---|---|

| Accuracy | Data matches actual product details |

| Completeness | All relevant information is included |

| Consistency | Data stays uniform across all platforms |

| Timeliness | Information is always up to date |

Consider adopting a modern solution to unlock these benefits for your team.

Click the banner below to try FineBI for free and empower your enterprise to transform data into productivity!

What is Product Lifecycle Management

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

What is a data management platform in 2025

A data management platform in 2025 centralizes, organizes, and activates business data, enabling smarter decisions and real-time insights across industries.

Howard

Dec 22, 2025

Top 10 Database Management Tools for 2025

See the top 10 database management tools for 2025, comparing features, security, and scalability to help you choose the right solution for your business.

Howard

Dec 17, 2025

Best Data Lake Vendors For Enterprise Needs

Compare top data lake vendors for enterprise needs. See which platforms offer the best scalability, integration, and security for your business.

Howard

Dec 07, 2025