Maintenance management helps you keep your business assets running smoothly. You use maintenance management to plan, organize, and monitor activities that prevent breakdowns and reduce downtime. Effective maintenance management supports operational efficiency and helps you control costs. When you apply maintenance management, you avoid unexpected failures and keep your business running without interruption. Modern maintenance management focuses on optimizing assets, not just fixing problems. You can now use digital tools and software like FineBI to transform your approach to maintenance management. These solutions help you make smarter decisions and improve how you manage maintenance management every day.

Maintenance management is the process you use to keep your company’s assets and resources in top condition. You plan, organize, and control activities that help your equipment work efficiently and avoid unexpected breakdowns. Maintenance management covers everything from routine inspections to advanced monitoring using digital tools. You focus on making sure your assets last longer and perform better.

In today’s business world, maintenance management goes beyond simple repairs. You use it to optimize asset management, improve productivity, and reduce costs. Modern maintenance management uses real-time data, sensors, and analytics to predict problems before they happen. This approach helps you make smarter decisions and keep your operations running smoothly.

Maintenance management is essential for every business that relies on equipment, machinery, or facilities. You use it to ensure efficient production and effective resource use.

When you practice maintenance management, you aim to achieve several important goals:

Maintenance management covers a wide scope. You manage everything from daily maintenance tasks to long-term asset management strategies. You use both preventive and predictive methods to keep your equipment in good shape. With the rise of digital technologies, maintenance management now includes data-driven decision-making, continuous monitoring, and sustainability practices.

| Feature | Traditional Maintenance | Modern Maintenance |

|---|---|---|

| Approach | Reactive/Preventive | Predictive |

| Monitoring | Periodic checks | Continuous monitoring |

| Data Usage | Minimal | Real-time data analysis |

| Technology | Limited | Advanced analytics/AI |

| Maintenance Scheduling | Fixed intervals | Just-in-time |

| Example | Scheduled downtime | Sensors predicting failures |

Maintenance management has evolved. You now use advanced tools and strategies to support asset management and business success.

Maintenance management means you take control of your equipment, facilities, and assets to keep them running at their best. You use maintenance management to plan, schedule, and monitor all activities that prevent breakdowns and extend the life of your assets. When you apply maintenance management, you focus on reducing costs, improving safety, and boosting productivity across your business.

You gain many advantages when you invest in maintenance management. These maintenance management benefits include lower expenses, fewer accidents, and higher efficiency. You also improve asset management by making sure your equipment works reliably and meets industry standards. Let’s look at the main benefits of maintenance management and how you can achieve them in your business.

You save money and increase efficiency when you use maintenance management. By planning regular inspections and repairs, you avoid expensive emergency fixes and reduce downtime. You also make better use of your resources and extend the lifespan of your equipment.

You also improve operational efficiency by shifting from reactive to proactive strategies. Proactive measures like predictive and preventive maintenance help you use your assets better and save money. Modern maintenance management software, such as FineBI, supports these efforts by providing tools for work order tracking, scheduled maintenance optimization, and data-driven analytics. FineBI helps you connect data from different sources, visualize trends, and make informed decisions that lead to cost savings.

Maintenance management benefits your business by making your workplace safer and helping you meet regulations. You reduce risks to people and equipment by using maintenance management software that triggers alerts for immediate inspections. This reduces the chance of accidents and ensures you follow safety guidelines.

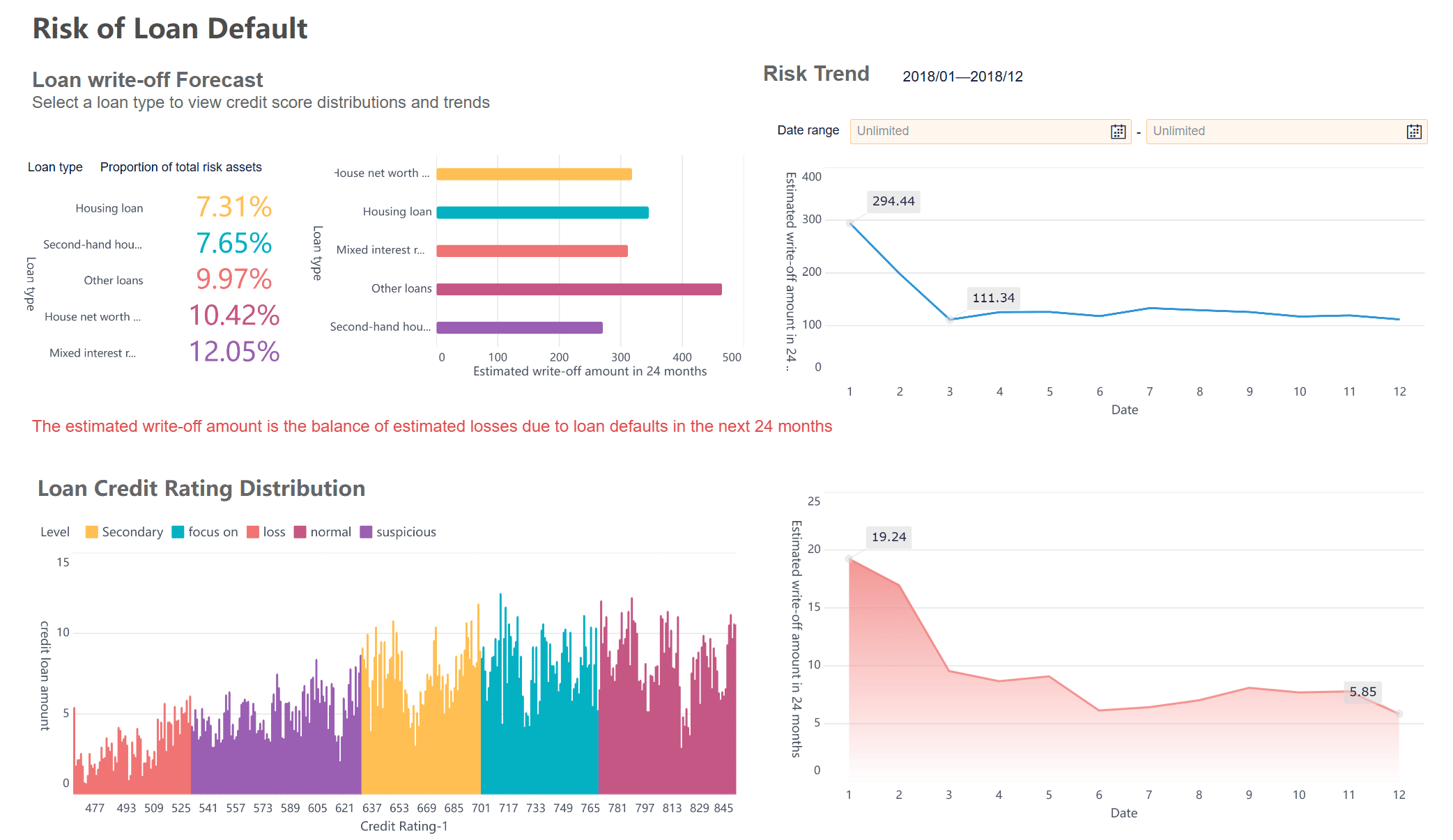

You also see a boost in productivity. Maintenance management allows you to track important metrics and spot issues before they affect your operations. In manufacturing, you often measure productivity using metrics like Overall Equipment Effectiveness (OEE), Mean Time to Repair (MTTR), and Maintenance Cost Ratios.

| Metric | Description |

|---|---|

| Overall Equipment Effectiveness (OEE) | Measures how efficiently your manufacturing process runs. |

| Mean Time to Repair (MTTR) | Shows the average time it takes to fix equipment. |

| Maintenance Cost Ratios | Assesses how cost-effective your maintenance is. |

By tracking these metrics, you improve repair efficiency, increase equipment reliability, and ensure your operations run smoothly. FineBI supports this process by offering real-time dashboards and analytics, so you can monitor safety, compliance, and productivity in one place.

You see the real benefits of maintenance management in manufacturing environments. Companies that use maintenance management practices report fewer breakdowns, less downtime, and higher output. For example, a fleet management company used AI-powered predictive maintenance to monitor vehicle health. They reduced breakdowns by 70% and minimized downtime by up to 50%. A wind energy company combined vibration analysis and thermal imaging to monitor turbines, reducing downtime by 60% and increasing energy production by 8%. In the food and beverage industry, predictive maintenance helped reduce packaging defects by 80% and ensured compliance with safety regulations.

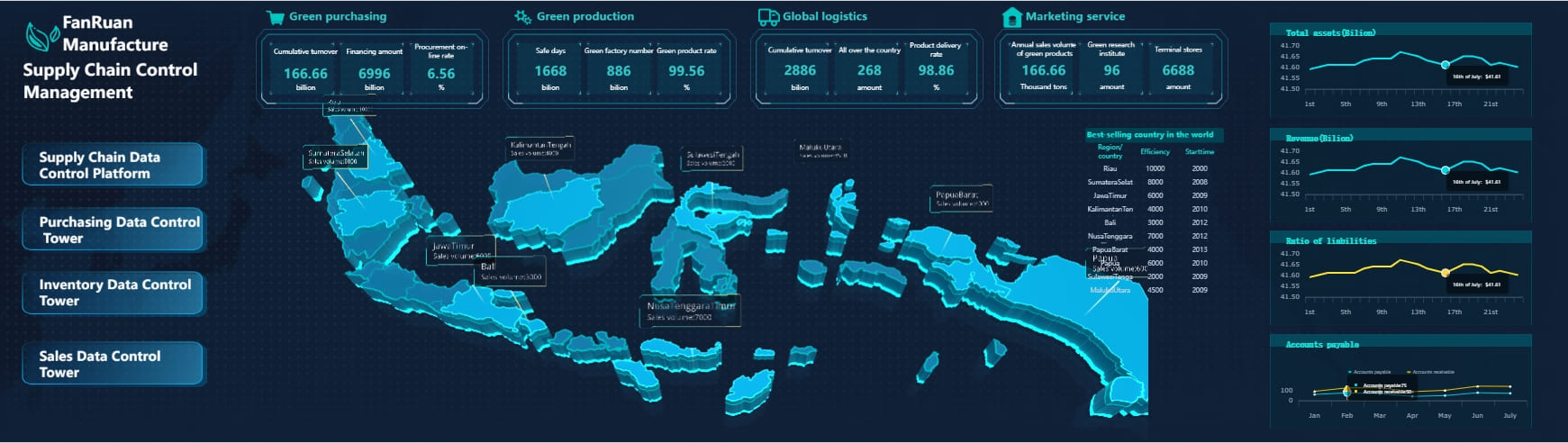

You can also look at the Danfoss story. Danfoss, a global leader in energy efficiency, transformed its manufacturing operations by adopting digital maintenance management. The company used FineReport and handheld devices to collect real-time data, monitor equipment, and streamline workflows. As a result, Danfoss increased operational efficiency by 2.8%, improved OEE by 3%, and reduced customer complaints by 57% over two years. The company also achieved significant cost savings and improved sustainability.

FineBI plays a key role in enabling data-driven maintenance decisions. With features like network inspection, component checks, and real-time analytics, FineBI helps you detect issues early and take action before problems grow. You can integrate data from multiple sources, visualize trends, and share insights across your team. This approach strengthens your asset management strategy and delivers the full benefits of maintenance management.

When you use maintenance management, you gain cost savings, improved safety, and higher productivity. You also build a stronger asset management system that supports your business goals and keeps your operations running smoothly.

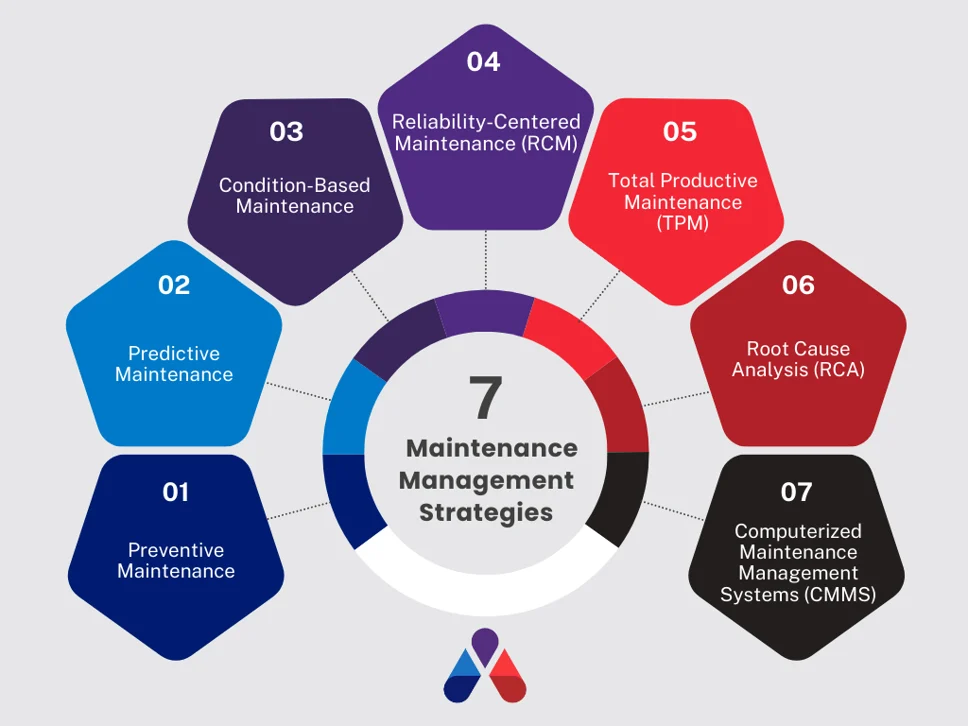

Maintenance management gives you the tools to keep your assets working efficiently. You use maintenance management to choose the right approach for your equipment, facilities, and business goals. Maintenance management means you plan, schedule, and monitor activities that prevent breakdowns and reduce downtime. You rely on maintenance management to support asset management and improve your maintenance program.

You use preventive maintenance to schedule regular servicing and inspections. This preventive maintenance strategy helps you reduce unexpected failures and control costs. Preventive maintenance works best for equipment with predictable failure patterns. You create a maintenance program that includes routine checks and servicing based on manufacturer recommendations or historical data.

Predictive maintenance uses real-time data and sensors to monitor equipment health. You analyze trends and detect issues before they cause breakdowns. Predictive maintenance helps you minimize downtime and improve maintenance scheduling. You need IoT sensors and analytics tools to implement predictive maintenance effectively. This approach gives you more control over your maintenance planning and asset management.

Tip: Proactive machine health monitoring leads to fewer unplanned outages and better equipment safety.

| Maintenance Type | Benefits | Limitations |

|---|---|---|

| Preventive Maintenance | Scheduled maintenance reduces unexpected breakdowns. | May lead to unnecessary maintenance costs. |

| Best for equipment with predictable failure patterns. | Not suitable for equipment with random failures. | |

| Predictive Maintenance | Proactive monitoring allows for early detection of issues. | Requires IoT sensors for effective implementation. |

| Reduces unplanned downtime and improves scheduling. | Initial setup costs can be high. |

Reactive maintenance means you fix equipment only after it fails. You use this approach when repairs are less expensive than regular servicing. Reactive maintenance is common for vehicles, hospitality assets like HVACs, and infrastructure projects. You may choose reactive maintenance for assets that are not critical to operations or have low repair costs.

You face higher downtime risk with reactive maintenance. You address failures after they happen, which can lead to increased costs and lost productivity. Maintenance management helps you decide when reactive maintenance is appropriate for your maintenance program.

| Maintenance Strategy | Downtime Risk | Description |

|---|---|---|

| Reactive | Very High | Addresses failures only after they occur, leading to increased downtime and costs. |

| Preventive | Medium | Scheduled servicing to reduce unexpected failures, resulting in moderate downtime. |

| Predictive | Low | Uses real-time data to address faults before they occur, significantly minimizing downtime. |

You select the best maintenance management strategy by considering your asset management needs, budget, and operational goals. You assess the criticality of your equipment and the skills of your staff. Maintenance management requires you to balance cost, compliance, and reliability.

| Criteria | Description |

|---|---|

| Asset Criticality | Identify which equipment is essential for operations. |

| Budget and Resources | Assess if predictive maintenance tools are affordable. |

| Industry Regulations | Consider compliance requirements that may influence practices. |

| Operational Goals | Define objectives like cost reduction or uptime maximization. |

Maintenance management supports your decision-making process. You use maintenance scheduling and a maintenance program to optimize asset management and achieve your business objectives.

Maintenance management software gives you the power to control your maintenance management processes with greater accuracy and speed. You use these digital tools to bring together data from different sources, track key performance indicators, and monitor your assets in real time. Maintenance management software helps you move from manual tracking to automated systems, making it easier to plan, schedule, and analyze maintenance activities.

You benefit from maintenance management software in several ways:

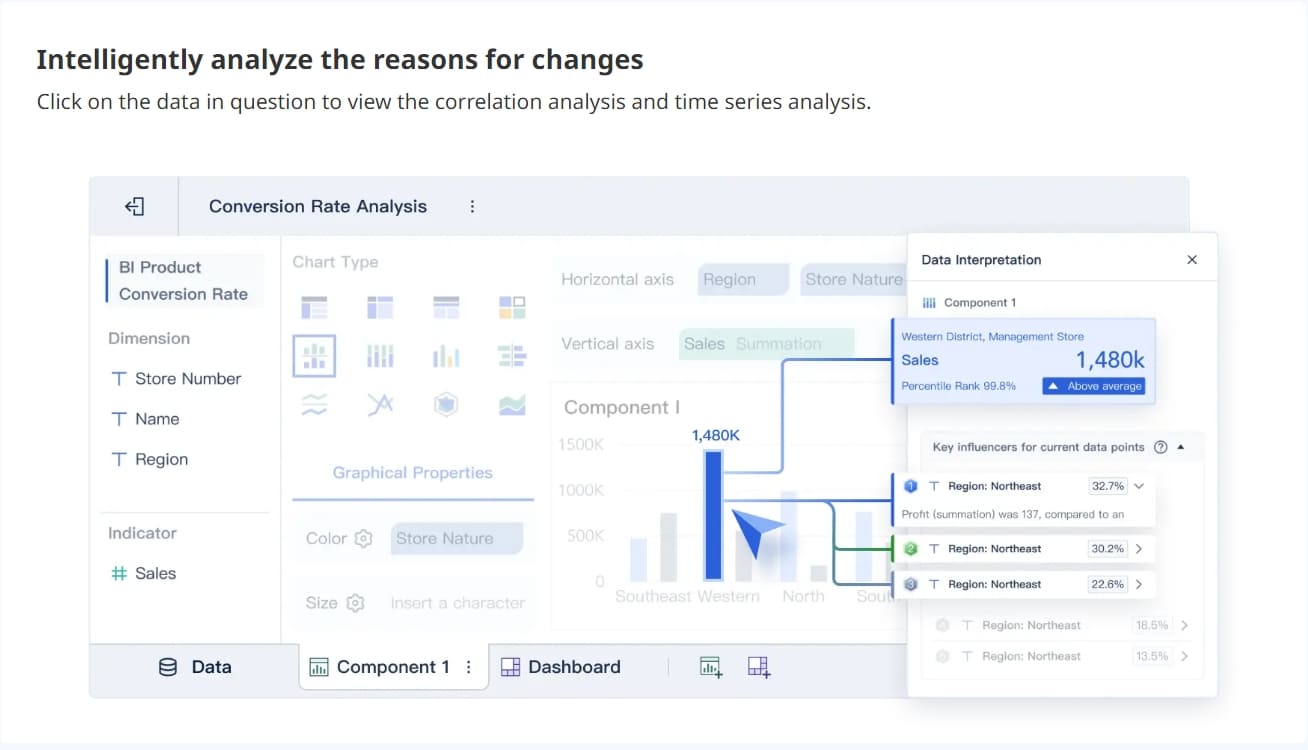

Visualizations play a key role in maintenance management technologies. They turn complex data into simple charts and graphs that everyone can understand. This clarity helps you and your team discuss maintenance budgets and strategies without confusion. Maintenance management software also supports collaboration by allowing technicians and managers to share insights and work together more effectively.

| Benefit | Description |

|---|---|

| Proactive Interventions | Prevents downtime by addressing issues before they escalate. |

| Operational Efficiency | Streamlines communication by presenting complex information in a digestible format. |

| Trend Analysis | Enables identification of long-term trends for predictive maintenance strategies. |

| KPI Tracking | Allows monitoring of critical metrics at a glance, triggering timely actions. |

| Dashboards | Aggregates essential data into a single interface for comprehensive asset health overview. |

| Predictive Analytics | Forecasts asset failures, guiding maintenance schedules for timely interventions. |

| Heatmaps and Timelines | Visualizes historical data, highlighting peak usage times and recurring issues. |

Maintenance management trends show that more businesses are adopting advanced maintenance management technologies. You see a shift toward predictive analytics, real-time monitoring, and integrated data platforms. These trends help you stay ahead by preventing failures and improving asset performance.

FineBI stands out as a leading maintenance management software solution. You use FineBI to connect data from multiple sources, create interactive dashboards, and analyze maintenance management activities in real time. FineBI’s self-service analytics let you explore data without needing technical skills, making it accessible for everyone on your team.

Key features of FineBI that support maintenance management include:

Compared to traditional maintenance management software, FineBI offers more flexibility and user-friendly tools. You can quickly build reports, track maintenance management trends, and collaborate across teams. In manufacturing equipment management, FineBI enables predictive maintenance, which can save you 30-40% over reactive approaches and reduce unscheduled downtime by up to 45%. You also eliminate most catastrophic breakdowns, ensuring your production stays on schedule.

Analytics and data visualization in FineBI help you make smarter decisions. You see all your maintenance management data in one place, spot patterns, and adjust your strategies for better results. Maintenance management technologies like FineBI drive the latest maintenance management trends, helping you achieve higher efficiency and lower costs.

Maintenance management means you take a structured approach to keeping your assets reliable and productive. You use maintenance management to plan, organize, and monitor all activities that keep equipment running and prevent unexpected failures. Effective maintenance management helps you reduce costs, improve safety, and ensure your business operates smoothly.

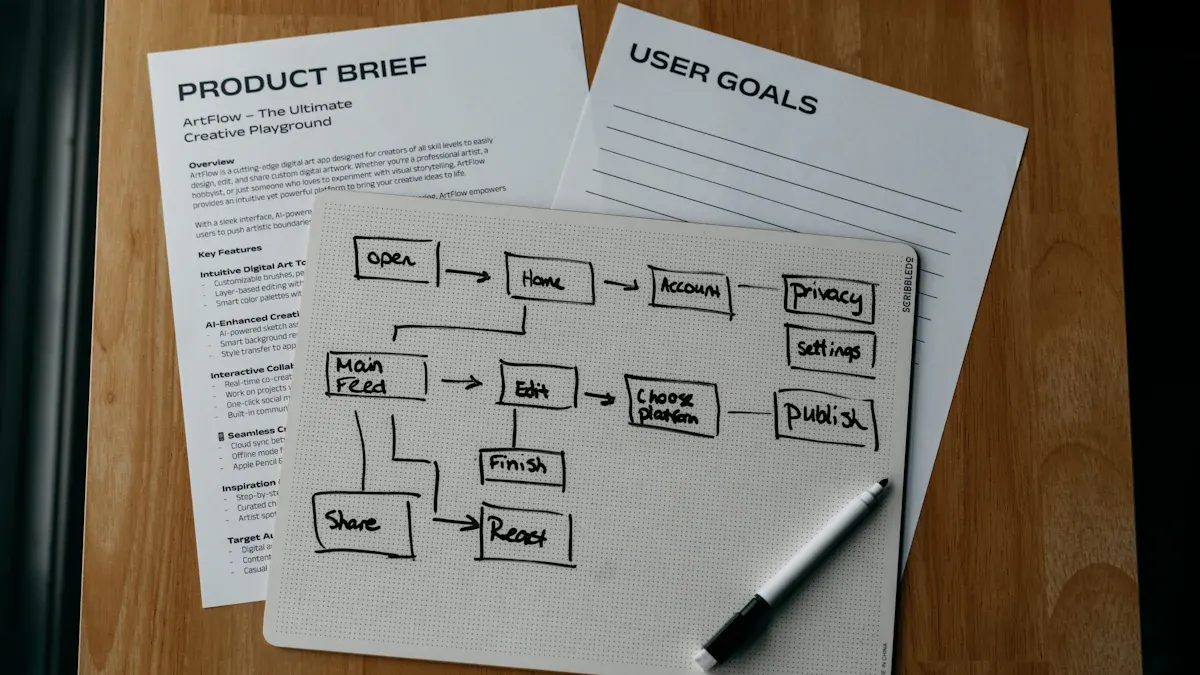

When you follow effective maintenance management practices, you create a system that supports your goals. You track maintenance management metrics, schedule preventive tasks, and use data to make better decisions. An effective maintenance management plan gives you the tools to measure performance and adjust your strategy as your business grows.

You can build an effective maintenance management plan by following proven steps:

You can also improve your maintenance management practices by implementing a computerized maintenance management system, collecting feedback from staff, and standardizing your processes.

You may face several maintenance management challenges when you start or improve your system. Misalignment with your organization’s needs can slow progress. Make sure your software matches your specific maintenance management requirements. Insufficient user training often leads to mistakes. Provide comprehensive onboarding for your team.

Resistance from staff members is another common issue. Involve employees in the selection process to build support. Technical infrastructure limitations can block success. Assess your current technology and address any gaps. Poor software integration may disrupt workflows. Choose solutions that work well with your existing systems.

To achieve effective maintenance management, you must monitor maintenance management metrics and adapt your plan as needed. FineBI helps you overcome maintenance management challenges by offering real-time analytics, easy data integration, and collaborative dashboards. You can use FineBI to track your maintenance management metrics, identify trends, and drive continuous improvement in your maintenance management practices.

Maintenance management helps you build a resilient business by keeping assets reliable and operations efficient. You gain cost savings, safer workplaces, and higher productivity when you use a coordinated approach.

| Findings | Description |

|---|---|

| Resilience Factors | Organizations with coordinated systems are more resilient to disruptions compared to those operating in silos. |

| Integration Benefits | Coordinated delivery systems enhance effectiveness and efficiency, reducing resource wastage. |

To upgrade your maintenance management, start by defining tasks, planning priorities, estimating resources, and using digital tools like FineBI for real-time tracking and analysis.

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

What is a data management platform in 2025

A data management platform in 2025 centralizes, organizes, and activates business data, enabling smarter decisions and real-time insights across industries.

Howard

Dec 22, 2025

Top 10 Database Management Tools for 2025

See the top 10 database management tools for 2025, comparing features, security, and scalability to help you choose the right solution for your business.

Howard

Dec 17, 2025

Best Data Lake Vendors For Enterprise Needs

Compare top data lake vendors for enterprise needs. See which platforms offer the best scalability, integration, and security for your business.

Howard

Dec 07, 2025