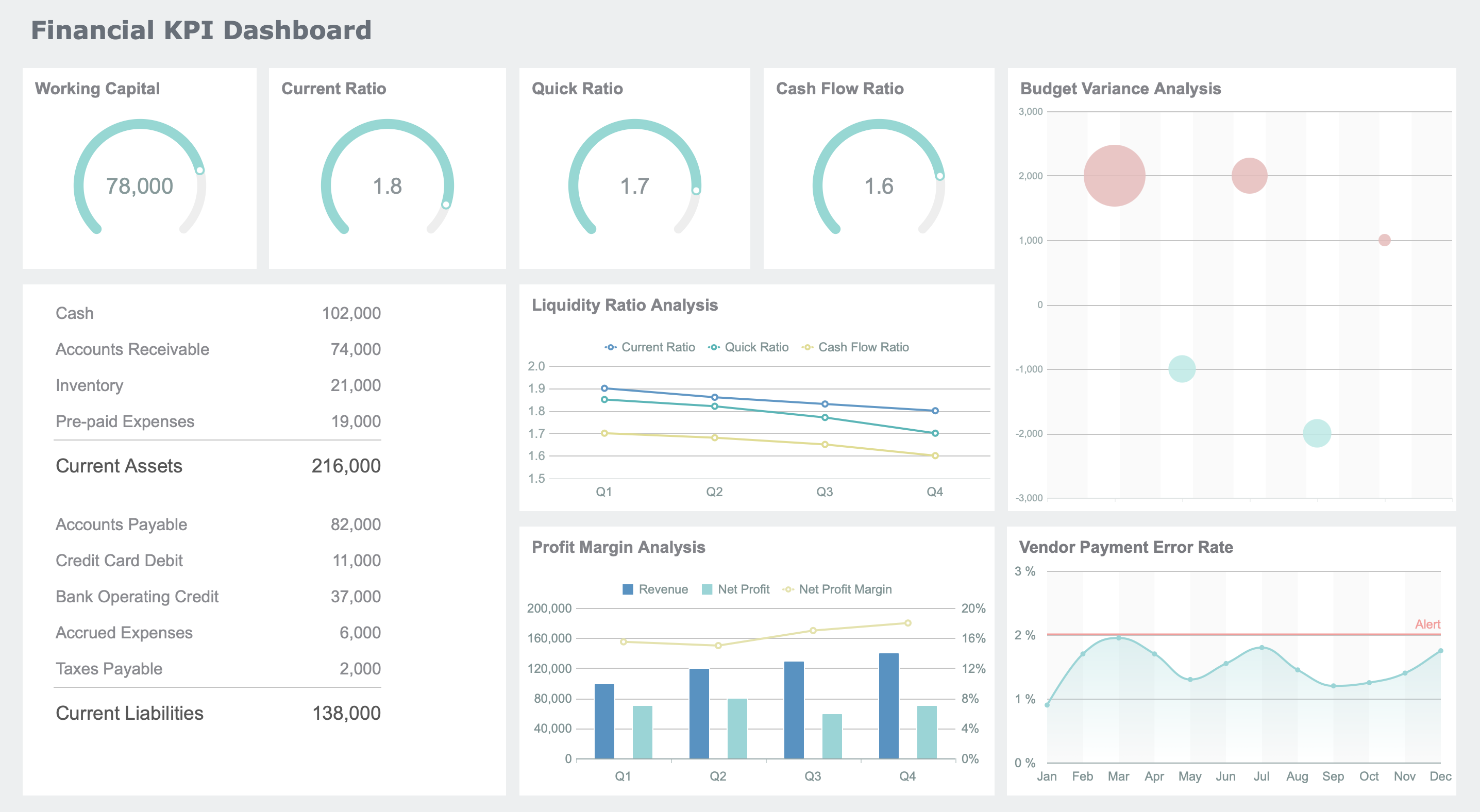

You rely on accurate data to keep your factory running smoothly. A manufacturing KPI dashboard gives you a clear view of your operations by consolidating critical metrics for real-time tracking. You can respond instantly to production changes and use AI-driven analytics for proactive decision-making. Solutions like FanRuan’s FineReport empower you to build dashboards tailored to your needs.

A manufacturing KPI dashboard acts as your command center for factory performance. It brings together the most important data, so you can spot trends, solve problems, and make decisions faster. With the right dashboard, you gain a clear view of your operations and can drive improvements across every department.

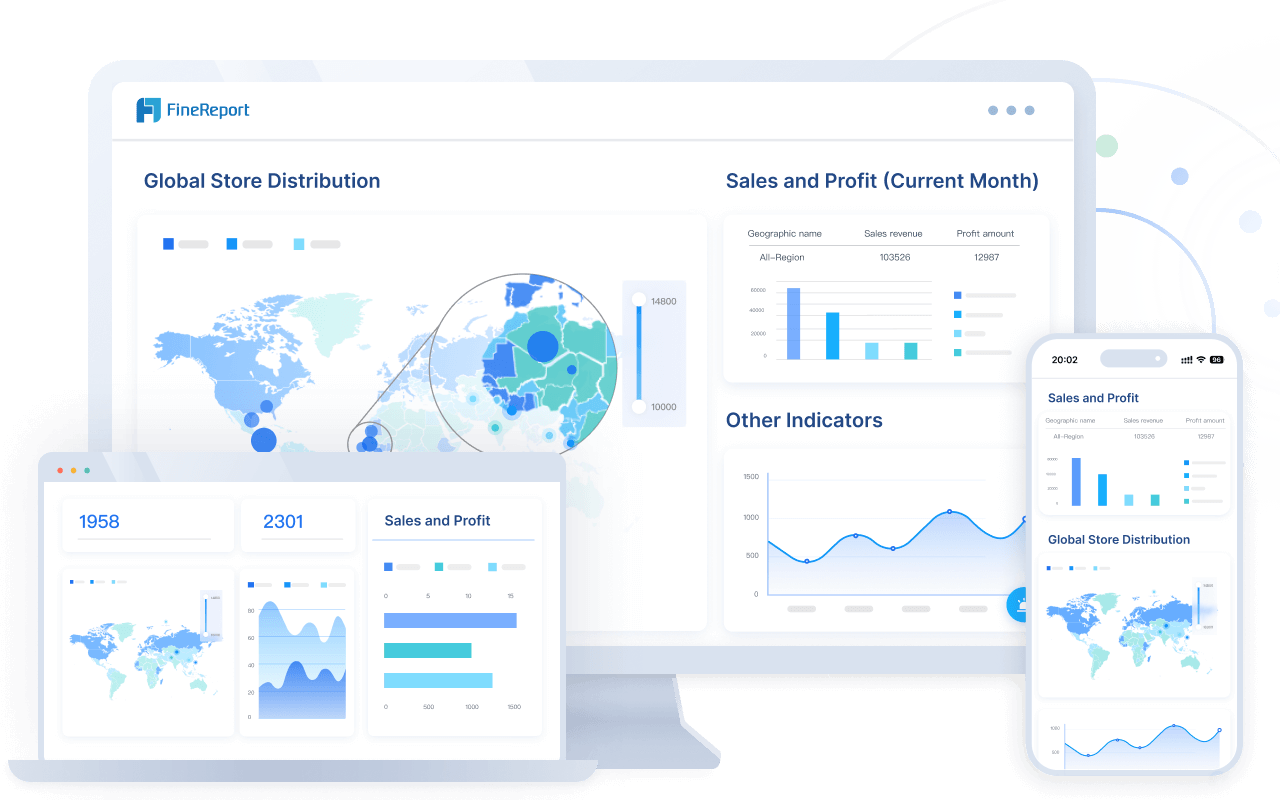

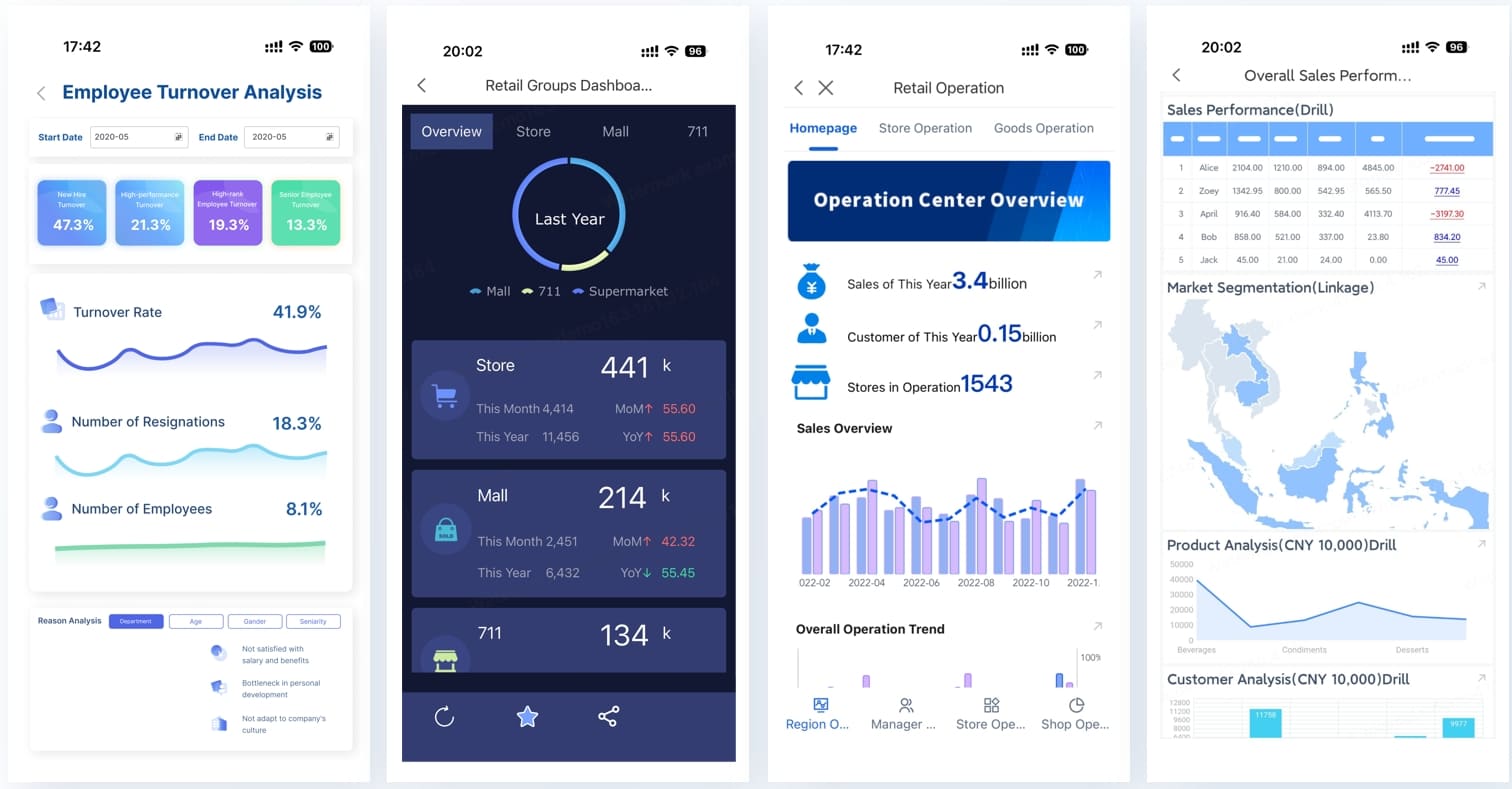

FanRuan and its FineReport platform stand out as trusted solutions for building dashboards and tracking KPIs in manufacturing. FineReport gives you the flexibility to connect to multiple data sources, visualize complex metrics, and customize dashboards for every team member. You can monitor production, quality, and efficiency in real time, helping you stay ahead of issues and meet your goals.

You need to start by identifying the key metrics that matter most to your operation. The right metrics give you a true picture of your factory’s health and performance. Most manufacturers focus on a core set of KPIs that reflect production, quality, and delivery. Here are some of the most commonly tracked metrics in a manufacturing KPI dashboard:

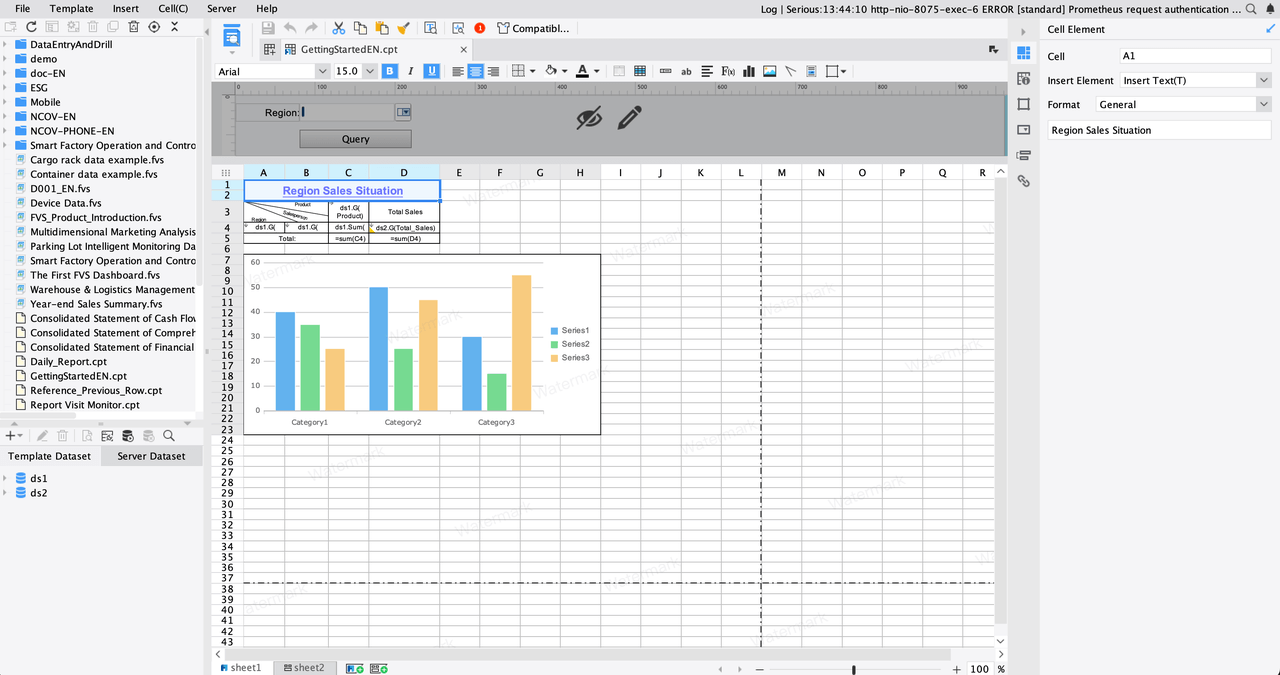

You can use FineReport to track these metrics in real time, visualize trends, and drill down into the details. This helps you quickly identify bottlenecks, reduce waste, and improve delivery performance.

You should always choose KPIs that support your business objectives. When you align your metrics with your goals, you make sure every action moves your factory forward. Leading manufacturers use several strategies to select the right KPIs:

FineReport makes it easy to connect your KPIs to your business strategy. You can customize dashboards to highlight the metrics that matter most for your team, whether you focus on quality, cost, or delivery.

Tip: Review your KPIs regularly to make sure they still match your goals. As your business changes, your metrics should evolve too.

Not every team member needs the same information. Operators, managers, and engineers each have unique needs. You should tailor your manufacturing KPI dashboard to fit each audience:

FineReport supports this level of customization. You can create role-based dashboards that deliver the right insights to the right people. This ensures everyone stays focused and can act quickly when issues arise.

A well-designed manufacturing KPI dashboard empowers your entire team. By defining key metrics, aligning them with your goals, and prioritizing for your audience, you set the stage for continuous improvement and operational excellence.

You need to understand your stakeholders before designing a manufacturing KPI dashboard. Each group in your organization has unique goals and information needs. Start by identifying who will use the dashboard and what decisions they must make. Consider these key factors:

When you focus on these steps, you ensure the dashboard delivers value to everyone, from operators to executives.

Choosing the right dashboard format is essential. Different user groups benefit from different types of dashboards. The table below shows how you can match dashboard types to user needs:

| Dashboard Type | Key Metrics | User Group |

|---|---|---|

| Real-time Dashboard | Inventory levels, machine status, production rates | Supervisors, Operators |

| Summary Dashboard | Sales performance, gross profit, service levels | CFO, Board Members |

| Mobile Dashboard | On-the-go access to key metrics, alerts for inventory and production issues | Sales Team, Executives |

Real-time dashboards help you track production metrics and operational efficiency. Summary dashboards give you insights into sales and service levels. Mobile dashboards let you access critical data anytime, anywhere. Many manufacturers use these dashboards to monitor assembly line efficiency, spot bottlenecks, and manage resources. You gain immediate insights that support informed decision-making.

FineReport gives you the flexibility to customize dashboards for every user group and device. You can create role-based dashboards that show only the most relevant metrics. FineReport supports real-time, summary, and mobile dashboards, so you can deliver the right information to the right people. Its drag-and-drop interface makes it easy to design dashboards that fit your workflow. You can also add interactive features, such as drill-downs and alerts, to help users explore data and respond quickly to changes. With FineReport, your manufacturing KPI dashboard adapts to your evolving business needs.

You want your manufacturing KPI dashboard to deliver information at a glance. Clear design helps you spot issues and make decisions quickly. Start by placing the most important data in the upper right corner of your dashboard. This area draws attention and ensures you see critical metrics first. Keep your layout consistent. Use the same style for buttons, titles, and data across all dashboards. This consistency helps you and your team navigate faster. Always choose font sizes and display locations that are easy to read, especially on large plant floor screens.

| Best Practice | Description |

|---|---|

| Information Layout | Place the most important information in the upper right corner, adjusting based on screen location. |

| Layout Consistency | Maintain a standard layout for buttons, titles, and data across dashboards for quick navigation. |

| Visual Accessibility | Consider font size and display location to ensure readability, especially on plant floor screens. |

FineReport’s drag-and-drop interface makes it easy to arrange charts, tables, and visuals. You can build dashboards that look professional and keep your team focused on what matters.

Interactive dashboards keep users engaged and support better decisions. You can drill down into data, set alerts, and customize views for different roles. Real-time updates let you respond to production issues as they happen. FineReport offers 3D components and dynamic charts, making complex data easy to understand.

| Feature | Description |

|---|---|

| Clarity and Simplicity | Information is presented clearly, making complex data understandable through visualizations. |

| Real-time Data | Provides immediate data updates, allowing quick responses to production issues. |

| Customizability | Dashboards can be tailored to display metrics relevant to different user roles. |

| Interactivity | Users can engage with the dashboard, drill down into data, and set alerts for anomalies. |

You can tailor each dashboard to fit the needs of operators, managers, or engineers. This flexibility ensures everyone gets the right information at the right time.

Mobile access changes how you use your manufacturing KPI dashboard. With 98% of Americans owning smartphones, you can check key metrics from anywhere. Mobile dashboards give you real-time updates on production, costs, and performance. You stay connected to your factory, even when you are off-site. FineReport’s mobile dashboard adapts to any device, so you always have the latest data at your fingertips. This access helps your team collaborate and make decisions faster, keeping everyone aligned and informed.

Tracking the right KPIs gives you a clear picture of your factory’s performance. When you use a manufacturing kpi dashboard, you can monitor these metrics in real time and make smarter decisions. Let’s look at the most important KPIs you should track to boost efficiency, quality, and profitability.

Overall Equipment Effectiveness (OEE) stands at the heart of manufacturing performance. You use OEE to measure how well your equipment runs by looking at three factors: Availability, Performance, and Quality. When you break down OEE, you can spot where you lose time or quality and take action to fix it.

You also want to track related efficiency KPIs:

Each of these KPIs helps you find bottlenecks and areas for improvement. FineReport’s OEE dashboards let you visualize these metrics, drill down into the details, and act fast when you spot a problem. You can connect data from your MES, ERP, or other systems for a complete view of your operations.

Tip: Even a small increase in OEE can add significant value to your bottom line. Use your dashboard to track trends and set improvement targets.

Quality metrics help you maintain high standards and reduce waste. You need to track these KPIs to catch defects early and keep customers happy. Here are the most common quality metrics you should include in your dashboard:

| Metric | Description |

|---|---|

| Cost of Quality (CoQ) | Total cost of poor quality plus investments in quality improvement. |

| Defects | Measured by Defective Parts Per Million (DPPM) or Defects Per Million Opportunities (DPMO). |

| Customer Complaints | Number of complaints, rejects, or returns over a set period. |

| Scrap Rate | Percentage of materials that do not become finished products. |

| Yield | Measures how efficiently your process turns materials into good products. |

You can also track:

FineReport’s quality control dashboards help you monitor these metrics in real time. You can use interactive charts to analyze trends, compare production lines, and identify root causes of defects. This approach supports continuous improvement and helps you meet regulatory standards.

Note: High-quality products lead to fewer complaints and lower costs. Use your dashboard to spot issues before they grow.

Scrap rate and downtime have a direct impact on your costs and profits. High scrap rates mean you waste materials and money. Unplanned downtime stops production and can cost you thousands of dollars per hour.

| Cost Type | Impact on Revenue (%) | Description |

|---|---|---|

| Scrap and Rework Costs | Up to 2.2% | Direct costs from waste and inefficiencies in production. |

| Hidden Costs | N/A | Includes waste disposal, defect correction, and lost opportunities. |

| Effective Management of Waste | 0.6% | You can reduce costs with better waste management practices. |

When you track scrap rate and downtime in your manufacturing kpi dashboard, you can:

FineReport’s smart factory dashboards give you real-time alerts for downtime and scrap spikes. You can set up automated notifications, analyze root causes, and take action before small problems become big losses.

Pro Tip: Use your dashboard to compare downtime and scrap rates across shifts or lines. This helps you find best practices and share them across your factory.

With the right KPIs and a powerful dashboard, you gain the insights you need to drive continuous improvement. FineReport’s manufacturing solutions for OEE, quality control, and smart factory management help you stay ahead in a competitive market.

You can transform your factory’s efficiency by moving to paperless operations. Digital systems replace manual paperwork, reducing lost information and miscommunication. Employees often spend up to 30% of their shift managing documents, which leads to a 21.3% productivity loss. Human error from outdated paper-based workflows costs manufacturers billions each year. When you adopt digital solutions, you boost productivity by up to 50% and improve labor efficiency by 15-30%. Throughput can increase by 10-30%.

| Evidence | Description |

|---|---|

| Productivity Loss | Employees spend 5-15% of time reading info, 50% searching for documents. |

| Time Management | Workers spend 20-30% of their shift on paperwork. |

| Human Error Cost | Paper-based workflows cost manufacturers $10 billion annually. |

Digital dashboards centralize your data, making it easier to access and analyze. You eliminate lost paperwork and improve accountability across your teams.

Real-time monitoring changes how you manage your manufacturing kpi dashboard. You see accurate data that reflects current conditions, not yesterday’s results. Automated alerts notify you when performance drops or anomalies occur, so you can act fast. This approach saves time on analysis and presentation. You avoid information silos and encourage a team mentality.

FineReport integrates seamlessly with FanRuan’s FineDataLink. You process complex SQL and cross-database associations, output results to your application database, and reuse processed datasets. This integration speeds up dashboard display and accelerates report development.

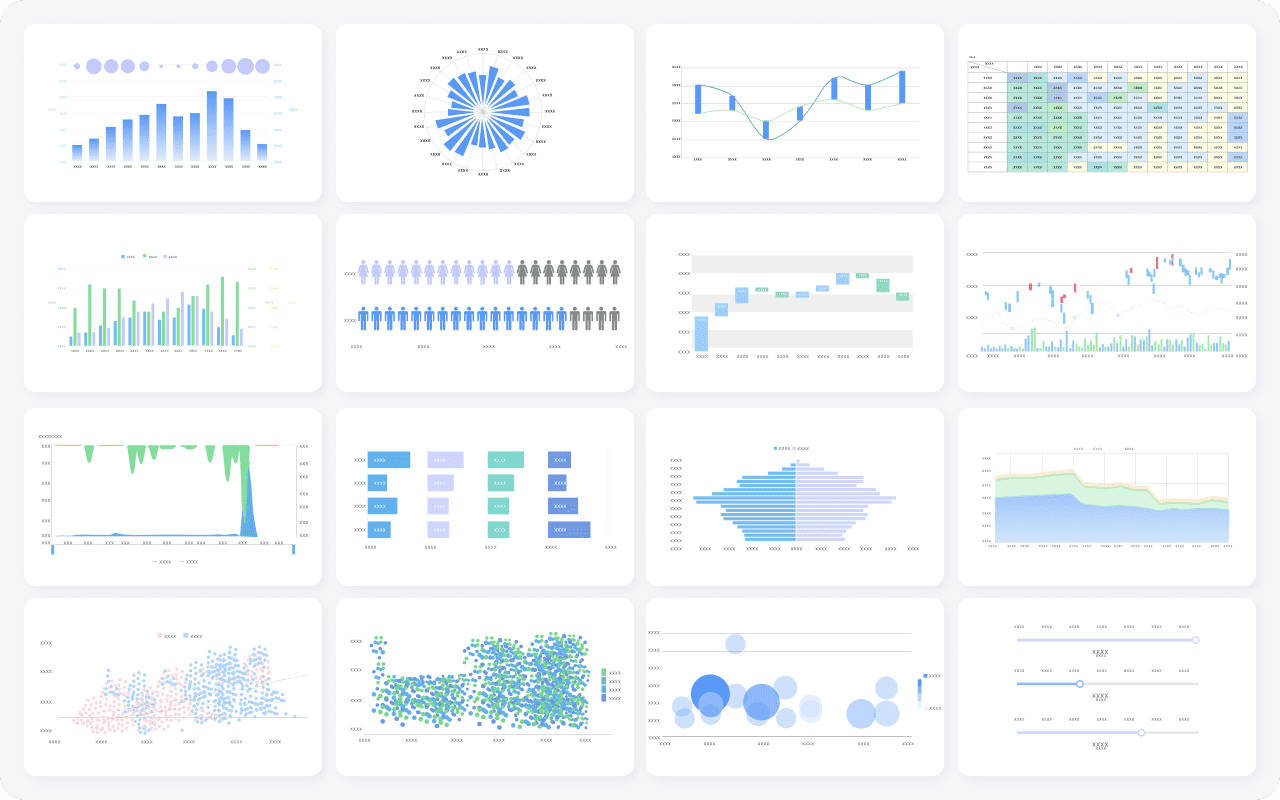

You need effective visualization formats to communicate performance metrics. Line and bar charts reveal trends. Heat maps highlight performance hotspots. Pie charts show composition analysis. Scatter plots uncover relationships and correlations.

| KPI Category | Examples |

|---|---|

| Primary | OEE, Production Yield, Downtime, Quality |

| Secondary | Maintenance Response, Inventory Turnover |

Visualization transforms complex datasets into clear graphics. You identify patterns and outliers quickly, making better decisions. Organize KPIs into categories for fast identification. Adopt Master Data Management practices to ensure data consistency and reliability. Regularly audit data sources and compare historical trends to maintain accuracy.

Tip: Foster a culture of data accountability. Train your team and automate data collection to reduce errors. Use feedback to refine your dashboard and streamline operations.

Building an effective manufacturing KPI dashboard requires clear goals, robust data collection, and regular review. Case studies show that companies like Toyota and Target achieved significant cost and inventory reductions by focusing on the right KPIs and investing in real-time data.

| Company | Key KPI Focus | Outcome | Recommendations |

|---|---|---|---|

| Toyota | OEE | 30% reduction in costs | Invest in IoT, review performance regularly |

| Target | Inventory | 15% less excess stock | Define metrics, align with objectives |

You can drive continuous improvement by setting S.M.A.R.T. targets, validating data, and adapting your dashboard as needs evolve. Start by reviewing your current KPIs or piloting a solution like FineReport to unlock actionable insights.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

What is a White Label Marketing Dashboard and How It Works

A white label marketing dashboard lets agencies present branded, automated reports and real-time insights to clients for improved engagement and retention.

Lewis

Jan 15, 2026

Strategy Dashboard Explained and Why Your Business Needs One

A strategy dashboard visualizes key metrics, tracks goals, and drives better decisions, making it vital for business performance and team alignment.

Lewis

Jan 15, 2026

Audit Dashboard Explained for CPA Firms

An audit dashboard centralizes audit data, streamlines workflows, and gives CPA firms real-time insights to boost efficiency and client satisfaction.

Lewis

Jan 15, 2026