Manufacturing operations management involves organizing and controlling the processes that turn raw materials into finished goods. You use this approach to improve efficiency, boost product quality, and reduce costs in your manufacturing environment. Effective management gives you a competitive edge by driving productivity and ensuring smooth operations. Digital transformation plays a major role, as most companies now invest in advanced technologies and data-driven tools. The table below shows how digital strategies impact manufacturing outcomes:

| Statistic | Implication |

|---|---|

| 90% of companies have experienced data loss due to a lack of proper data management. | Highlights the critical need for effective data management in manufacturing operations. |

| Poor data management practices can reduce a company’s operational efficiency by 21%. | Demonstrates the direct negative impact of data management on operational efficiency. |

| 76% of companies are investing in emerging technologies. | Indicates a trend towards digital transformation in the manufacturing sector. |

| Companies leveraging CRM systems have seen an increase in sales productivity by up to 34%. | Shows the positive outcomes of digital tools on productivity in manufacturing. |

| Digital transformation has significantly impacted sales efficiency. | Reflects the broader implications of digital strategies on overall business performance. |

Manufacturing operations management is the practice of organizing, controlling, and optimizing the activities that turn raw materials into finished products. You use manufacturing operations management to make sure every step in the manufacturing process runs smoothly, efficiently, and safely. This approach helps you deliver high-quality products on time and at the right cost.

You set clear goals when you implement manufacturing operations management. These goals guide your daily activities and help you measure success. Most organizations focus on objectives such as improving product quality, increasing output, reducing costs, and ensuring workplace safety. You also aim to support sustainability and meet customer demands. By setting these targets, you can identify bottlenecks and improve performance across your operations.

Note: Manufacturing operations management supports your business by aligning production goals with overall company strategy. This alignment helps you streamline workflows and respond quickly to changes in demand.

The main objectives of manufacturing operations management can be summarized in the table below:

| Objective | Description |

|---|---|

| Quality Focus | You focus on delivering optimal product quality at every stage. |

| Workforce Development | You train employees to maintain high standards and understand their roles. |

| Process Standardization | You implement systems like ISO 9001 to boost efficiency and consistency. |

| Integration of Technology | You use real-time data to make faster, more informed decisions. |

You also benefit from workforce empowerment, better quality control, and a competitive advantage by streamlining processes and delivering high-quality products quickly.

Manufacturing operations management covers several core functions that keep your manufacturing environment running at its best. Each function plays a key role in achieving your goals and improving operational performance.

The table below highlights the most common core functions in manufacturing operations management:

| Core Function | Description |

|---|---|

| Quality Management | You ensure quality is built into every step of production. |

| Supply Chain Management | You achieve real-time visibility and control over materials and products. |

| Data Analytics | You excel at collecting and analyzing data for better decision-making. |

| Manufacturing Operations Analytics | You monitor performance and drive continuous improvement. |

You also handle inventory storage, manage stock levels, oversee project workflows, enforce safety protocols, and train new employees. Each of these functions supports your overall management strategy and helps you align performance with your company’s strategic goals.

Tip: Ongoing communication and regular performance measurement help you foster a culture of continuous improvement. When you align your business units and set clear targets, you create a sense of ownership and purpose among your team.

Manufacturing operations management gives you the tools and structure you need to run an efficient, high-quality, and competitive manufacturing operation. By focusing on these core functions, you can respond quickly to challenges and drive long-term success.

Manufacturing operations management relies on several essential components to ensure your manufacturing processes run efficiently and deliver high-quality products. You use manufacturing operations management to coordinate planning, scheduling, quality control, inventory management, and process optimization. Each component supports your ability to meet production goals, reduce costs, and maintain a competitive edge.

Planning and scheduling form the backbone of manufacturing operations management. You start by forecasting demand using historical data and market trends. This helps you determine what products to make, when to make them, and how many to produce. Effective scheduling assigns jobs to resources, reduces production time, and increases output. Strategies like just-in-time scheduling and demand-driven planning help you avoid excess inventory and minimize lead times. Advanced planning software synchronizes processes, reduces waste, and creates realistic production schedules.

Note: The initial stages of planning involve demand forecasting and capacity planning. These steps ensure you use your resources efficiently and avoid bottlenecks.

Quality control is a core part of manufacturing operations management. You implement methods such as Six Sigma, Total Quality Management, and Statistical Process Control to monitor and improve product quality. Real-time monitoring with sensors allows you to detect issues immediately and make corrections during production. This proactive approach reduces defects, maintains customer satisfaction, and minimizes waste. Lean manufacturing principles, like the 5S framework, help you eliminate unnecessary steps and maintain high standards.

| Quality Control Method | Description | Key Elements/Frameworks |

|---|---|---|

| Six Sigma | Reduces defects using data-driven analysis. | DMAIC framework |

| Total Quality Management (TQM) | Focuses on organization-wide quality. | Employee involvement, process focus |

| Statistical Process Control (SPC) | Uses statistics to monitor processes. | Control charts, trend analysis |

| Lean Manufacturing | Eliminates waste while keeping quality high. | 5S framework |

Inventory management in manufacturing operations management ensures you have the right materials at the right time. You track materials, manage stock levels, and use techniques like ABC analysis and cycle counting to maintain accuracy. Automated inventory systems improve stock accuracy and prevent production downtime. Real-time data collection helps you avoid stockouts and keep manufacturing lines running smoothly. You also use technology to automate replenishment and centralize inventory, which reduces costs and improves supply chain reliability.

Process optimization is vital for increasing throughput and reducing waste in manufacturing operations management. You use real-time monitoring, predictive analytics, and Lean Six Sigma tools to identify inefficiencies and improve workflows. Data integration platforms help you analyze performance and make informed decisions. By continuously optimizing processes, you boost productivity and maintain high product quality.

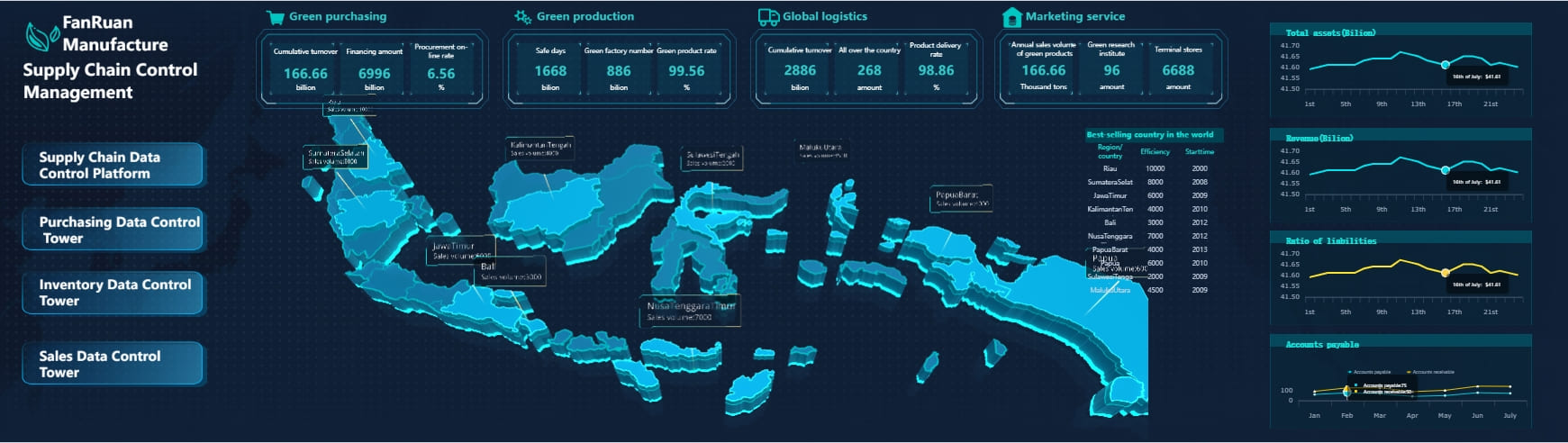

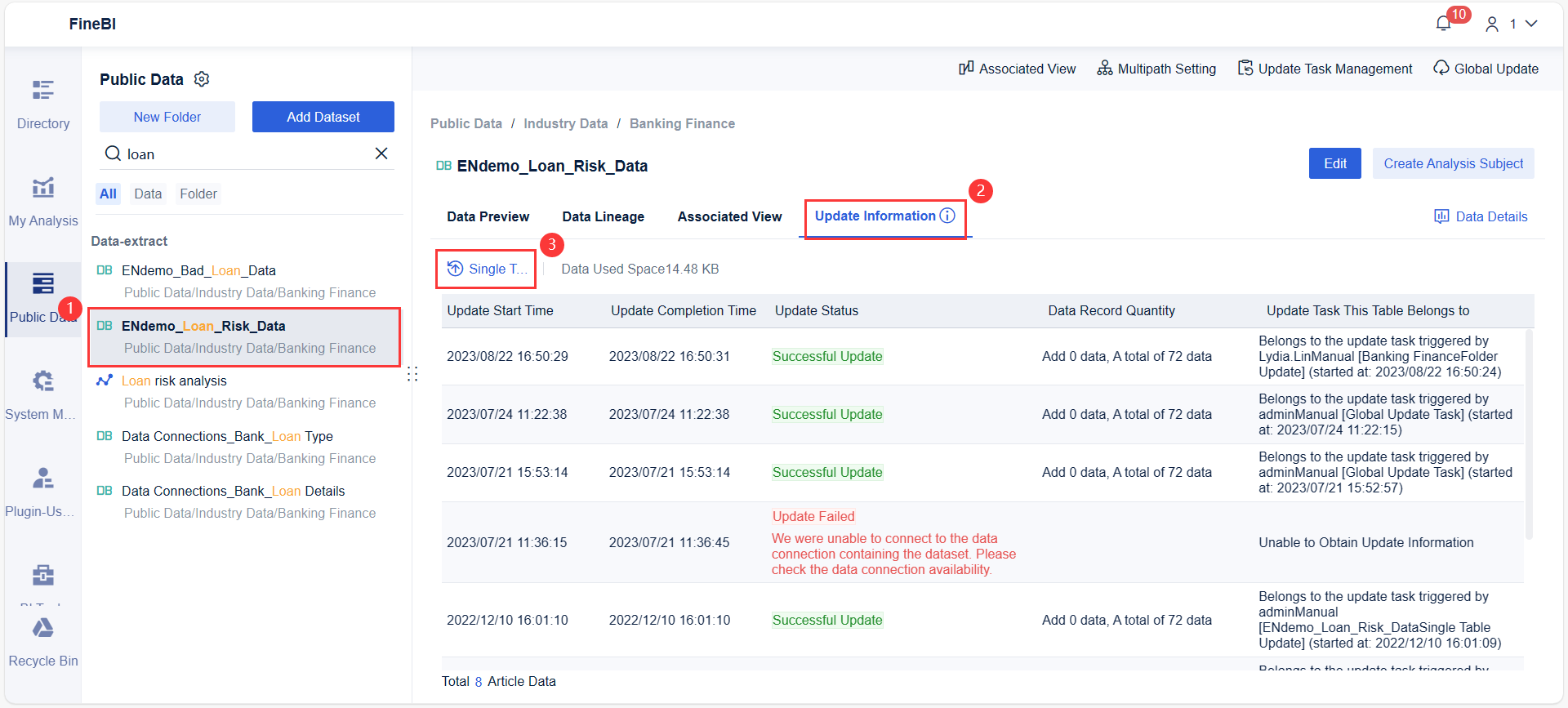

After establishing these key components, you can leverage advanced tools like FineBI to enhance your manufacturing operations management. FineBI enables you to integrate data from multiple sources, monitor operations in real time, and visualize performance through interactive dashboards. Its self-service analytics and data visualization features empower your team to identify trends, optimize processes, and make data-driven decisions quickly. With FineBI, you gain a unified view of your manufacturing environment, supporting continuous improvement and operational excellence.

Manufacturing operations management gives you the structure and tools to control every aspect of your production environment. You use manufacturing operations management to organize workflows, monitor performance, and ensure that your manufacturing processes deliver consistent results. This approach helps you meet customer demands, maintain high standards, and adapt quickly to changes in the market. By focusing on clear goals and continuous improvement, you can drive business productivity and achieve sustainable growth.

Manufacturing operations management plays a critical role in boosting efficiency and productivity. You gain real-time visibility into your production lines, which allows you to identify bottlenecks and optimize workflows. When you track work-in-progress and machine status, you can quickly respond to issues and prevent delays. Automated inspections and standardized processes help you reduce defects and improve product quality. Predictive maintenance alerts minimize unplanned downtime, so your equipment stays operational longer.

Here is a table that summarizes the measurable improvements you can achieve with manufacturing operations management:

| Improvement Area | Description |

|---|---|

| Improved Production Visibility | Real-time tracking helps you spot bottlenecks and optimize efficiency. |

| Enhanced Quality Control | Automated inspections reduce defects and improve product quality. |

| Reduced Downtime | Predictive maintenance prevents equipment failures and increases uptime. |

| Optimized Resource Utilization | Real-time data helps you use labor and materials more efficiently. |

| Faster Time to Market | Automated workflows speed up production cycles and delivery. |

| Lower Operational Costs | Process optimization reduces waste and improves profit margins. |

| Improved Traceability | Comprehensive tracking ensures compliance and quality assurance. |

| Better Data-Driven Decisions | Aggregated data supports continuous operational optimization. |

You also benefit from shorter manufacturing lead times. When you understand the total time required to produce and deliver a product, you can manage inventory more effectively and meet customer expectations. Lead time directly affects your profitability. Missed delivery dates can result in lost orders and damage your reputation. Delivery performance is essential for building strong customer relationships.

You can use workplace organization methods like 5S to minimize wasted time and movement. This leads to smoother workflows and quicker production. Efficient supply chain management also helps you fulfill orders promptly and keep your manufacturing lines running smoothly.

Manufacturing operations management helps you control costs and maintain high product quality. You streamline production processes to eliminate bottlenecks and reduce waste. Lean manufacturing principles allow you to enhance efficiency and cut unnecessary steps. Just-in-time inventory systems help you minimize holding costs and avoid overstocking.

Here are some practical ways you can reduce costs with manufacturing operations management:

You can also:

Effective cost management is essential for your business. By controlling costs and optimizing resources, you can improve profitability and support long-term growth.

Consistent product quality is another key benefit of manufacturing operations management. Automated inspections help you detect defects early and prevent costly rework. Production tracking software allows you to identify deviations from quality standards quickly. Root cause analysis helps you prevent recurring issues and maintain consistency across your production lines.

| Aspect | Contribution to Quality |

|---|---|

| Automated Inspections | Timely defect detection improves product quality. |

| Production Tracking | Quick identification of quality deviations. |

| Root Cause Analysis | Prevents recurring issues and ensures consistency. |

You also benefit from standardized procedures and data-driven decision-making. By tracking performance trends, you can optimize quality control and deliver reliable products to your customers.

Manufacturing operations management strengthens your competitiveness in the manufacturing sector. You integrate industrial policy and innovation strategies to stay ahead in high-cost economies. Technological innovation becomes essential for maintaining your competitive edge. By engaging with research organizations and adopting new technologies, you can transform innovations into commercially viable products.

You also improve your ability to deliver products on time and meet customer expectations. Managing lead times and delivery performance helps you build strong relationships and secure repeat business. When you maintain high standards and adapt quickly to market changes, you position your business as a leader in the industry.

Smart factory solutions provide real-world examples of how manufacturing operations management drives competitiveness. For instance, companies that implement integrated systems for real-time monitoring and control achieve higher efficiency and better product quality. These solutions connect equipment, automate logistics, and provide visual dashboards for tracking progress. As a result, you can respond to issues promptly and make informed decisions.

The Danfoss customer story demonstrates the impact of digital transformation in manufacturing operations management. Danfoss used handheld devices and advanced reporting tools to eliminate data silos and streamline workflows. The company achieved a 2.8% increase in operational efficiency, a 3% improvement in overall equipment effectiveness, and a 57% reduction in customer complaints. Real-time monitoring and paperless operations helped Danfoss save costs, improve energy efficiency, and reduce carbon emissions. These results show how effective management can transform your manufacturing environment and deliver measurable benefits.

FineBI supports your efforts by providing powerful tools for operational efficiency, quality improvement, and data-driven decision-making. You can integrate data from multiple sources, monitor operations in real time, and visualize performance through interactive dashboards. FineBI’s self-service analytics empower your team to identify trends, optimize processes, and make informed decisions quickly. With FineBI, you gain a unified view of your manufacturing operations, supporting continuous improvement and helping you stay competitive in a fast-changing market.

To begin implementing manufacturing operations management, you need to understand your current manufacturing environment. This means you should evaluate your processes, identify strengths and weaknesses, and look for opportunities to improve. Start by conducting a high-level analysis of losses and waste. Focus on areas that cause the most problems or delays. Use structured tools to help you with this assessment:

| Assessment Tool | Description |

|---|---|

| McKinsey 7-S model | Analyzes alignment between current and desired states. |

| SWOT analysis | Identifies strengths, weaknesses, opportunities, and threats. |

| Fishbone diagram | Finds root causes of issues in manufacturing processes. |

| DMAIC method | Uses a structured approach to improve processes and eliminate defects. |

Set clear goals for what you want to achieve with manufacturing operations management. Choose the right methodology, implement changes, and monitor progress. Adjust your processes as needed and work to sustain improvements over time.

Modern manufacturing operations management relies on technology to drive efficiency and quality. You can use systems like Manufacturing Execution Systems (MES), Supply Chain Management (SCM), and real-time analytics tools to monitor and control your operations. Data visualization platforms and real-time location systems help you track materials and equipment. Automation software, such as programmable logic controllers and distributed control systems, supports consistent production and reduces errors.

After you establish a strong foundation, consider integrating a platform like FineBI. FineBI connects your data sources, enabling real-time analysis and efficient data management. Its high-performance computing engine processes large volumes of data quickly. FineBI also supports collaboration, allowing your team to generate unified reports and monitor key metrics for continuous improvement.

To ensure successful manufacturing operations management, follow these best practices:

| Best Practice | Description |

|---|---|

| Invest in automation | Use automation and predictive analytics to optimize production and reduce costs. |

| Move toward digital | Adopt digital manufacturing to minimize risks and stay agile. |

| Focus on talent management | Recruit and retain skilled employees and encourage effective communication. |

| Create supply chain redundancy | Build multiple sources for materials to prepare for disruptions. |

| Increase visibility | Use real-time data to make informed decisions and respond quickly to changes. |

Continuous improvement is key. When you reduce waste and optimize processes, you lower costs and improve product quality. You also motivate your team to solve problems and adapt to new challenges. Manufacturing operations management, supported by digital tools like FineBI, helps you achieve long-term success and stay competitive in the manufacturing industry.

Manufacturing operations management gives you the structure to organize, control, and optimize your manufacturing processes. You improve efficiency, product quality, and competitiveness by using strong management practices. The table below highlights how manufacturing operations management impacts business performance:

| KPI | Impact on Business Performance |

|---|---|

| Production Capacity | Improves overall production capabilities |

| Productivity | Enhances efficiency and output levels |

| Product Quality | Boosts the quality of manufactured goods |

| Delivery Times | Optimizes the speed of product delivery |

| Waste Minimization | Reduces unnecessary waste in production |

| Cost Control | Helps in managing and reducing operational costs |

To move forward, you can:

By taking these steps, you set your organization up for long-term success in manufacturing.

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

Mastering Data Management: A Complete Guide

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025