Automated quality control uses advanced technology to inspect products quickly and accurately. You now see more manufacturers choosing automated systems, as over half use machine vision to boost inspection speed and consistency. Manual checks often miss defects due to fatigue, but automated inspection reduces errors and keeps quality high. With real-time data integration and analytics, solutions like FineReport help you spot problems early and make smarter decisions. This shift improves quality control and supports higher production demands.

You see automated quality control changing how factories keep products consistent and safe. Automated quality control in manufacturing uses tools like sensors, cameras, and artificial intelligence to inspect and test products during production. These systems check every item against strict standards. You no longer rely only on human inspectors. Automated systems work faster and catch more defects than people can. They use real-time data to spot problems and help you improve the quality control process.

You gain several advantages when you use automated quality control. You ensure products meet high standards every time. You reduce defects and avoid costly rework. You monitor quality parameters as production happens, so you can fix issues right away. Automated inspection systems also help you optimize production and reduce waste. You keep customers happy by delivering reliable products. You meet regulatory requirements and maintain transparency in your supply chain. You also support continuous improvement by using data and analytics. Automated quality control connects with Industry 4.0 technologies like IoT and big data, helping you stay competitive.

Tip: Automated quality control lets you inspect products at high speed and with great accuracy. You can detect problems early and prevent large-scale defects.

Automated quality inspection uses advanced technology to check products for defects. You use high-resolution cameras, sensors, and AI algorithms to scan items in real time. These automated inspection systems give you quick and objective results. You avoid the problems of manual inspection, such as fatigue and human error. Automated inspections run nonstop and can check every product at maximum speed.

You notice big differences between manual and automated inspection. Manual quality inspection depends on people, who may miss defects or make mistakes. Automated inspection systems use machine vision and AI to deliver consistent and accurate results. For example, in the automotive industry, machine vision improved defect detection by 30% and cut inspection time in half. Automated inspection systems adapt and learn over time, making them even more effective.

Here is a table that shows the main differences between manual and automated quality inspection:

| Aspect | Manual Quality Inspection | Automated Quality Inspection |

|---|---|---|

| Accuracy | Misses up to 15% of defects; falsely rejects 35% of good parts due to human fatigue, bias, and variability. | Achieves 99%+ detection accuracy with consistent, objective defect detection using AI and sensors. |

| Speed | Slower inspection limited by human speed and fatigue. | Real-time inspection at line speed, enabling rapid defect detection. |

| Consistency | Variable results due to subjectivity and fatigue. | Consistent application of standards without fatigue or bias. |

| Scalability | Limited scalability; difficult to increase throughput without more inspectors. | Easily scalable to high-volume production without additional labor costs. |

| Cost | Lower upfront cost but higher long-term costs due to errors, rework, and labor. | Higher upfront investment but ROI typically within 12 months due to efficiency gains. |

| Role in Industry | Used for edge cases, novel defects, and regulatory sign-offs. | Handles routine, repeatable checks and large volumes efficiently. |

| Hybrid Approach | Combined with automation for best results, routing ambiguous cases to humans. | Supports continuous improvement through AI learning from human feedback. |

You use automated inspection to find many types of defects. These include surface scratches, dents, stains, and contamination. You can spot dimensional errors, incorrect assembly, and missing parts. Automated inspection systems also catch labeling issues, packaging defects, microcracks in electronics, and material flaws in medical devices. You use optical inspection for surface defects, laser scanning for dimensional errors, and non-destructive testing for internal flaws. Automated inspection systems work across industries, from manufacturing to healthcare.

You benefit from automated inspection systems because they inspect every product, scale with your production, and provide valuable data for improving quality control processes. You use controllers to analyze sensor data and actuators to remove defective products or adjust the production line automatically. Automated inspections help you maintain high standards and keep your operations efficient.

You rely on several key components of automated quality control to keep your production line running smoothly. Automated inspection systems use advanced sensors, cameras, and software to check products for defects. You see laser measurement sensors, vision sensors, and imaging tools working together to inspect every item. These technologies help you catch tiny flaws that human eyes might miss.

Here is a table showing some of the most widely used quality control technology in automated systems:

| Technology Type | Example Products / Technologies | Key Features and Uses |

|---|---|---|

| Laser Measurement Sensors | Q4X Series, LM Series | Precise part inspection; detects sub-millimeter changes; rugged design; tracks performance |

| Vision Sensors | iVu Series | Monitors type, size, orientation, shape, location, and color variations |

| Advanced Imaging | SEM with EDS | Detailed surface and elemental analysis; automated image reporting |

| Automation Software | Avizo 2D | Automates image analysis and reporting; uses AI for material characterization |

| Communication Protocols | IO-Link | Tracks sensor performance; identifies trends; supports predictive maintenance |

Automated inspection systems use machine vision and artificial intelligence to boost accuracy. You benefit from high-resolution cameras and AI algorithms that detect defects, measure dimensions, and verify product quality. These automated systems work faster than manual checks and deliver consistent results. AI-powered computer vision can reach defect detection rates up to 99.9%, making automated inspection ideal for repetitive tasks. You train these systems with example images, so they learn to spot subtle defects and adapt to changing environments.

Note: Automated inspection systems reduce human error and fatigue, helping you maintain high standards and improve workflow efficiency.

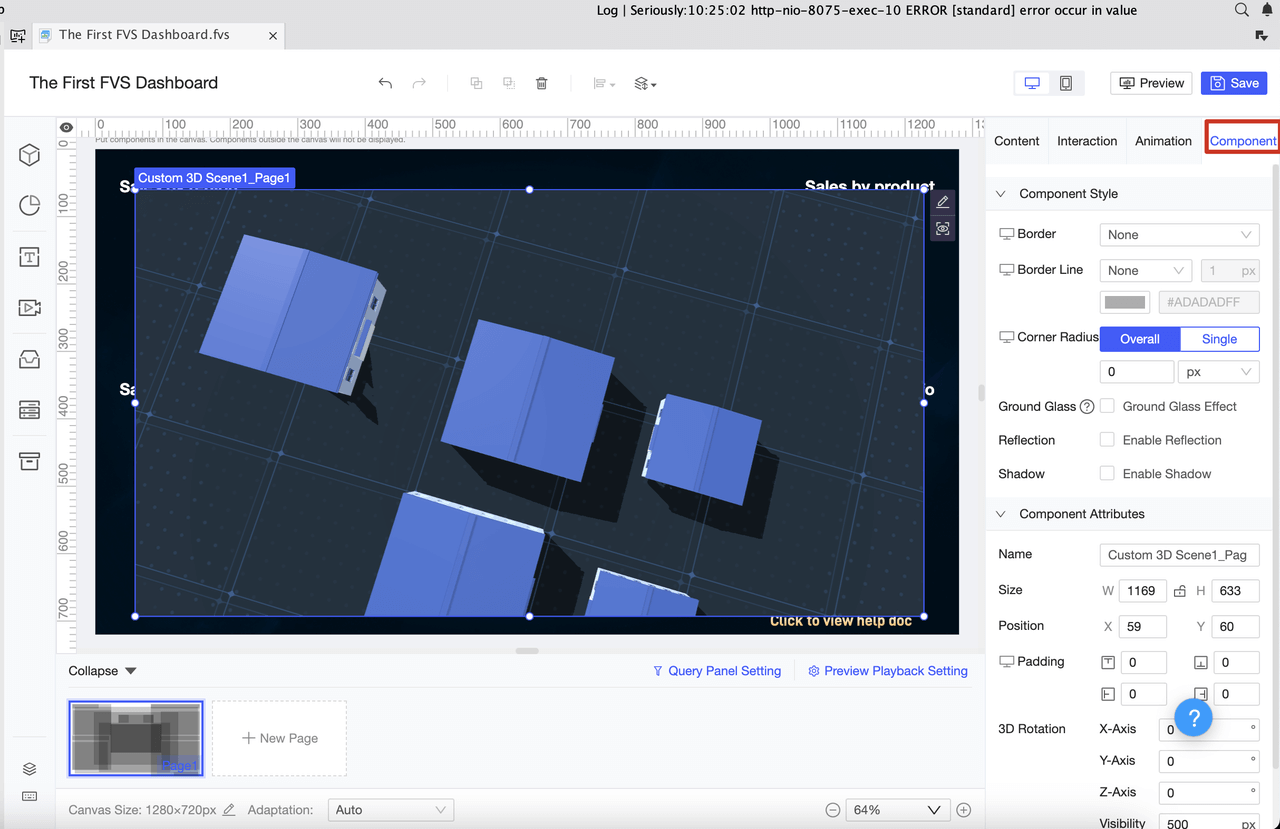

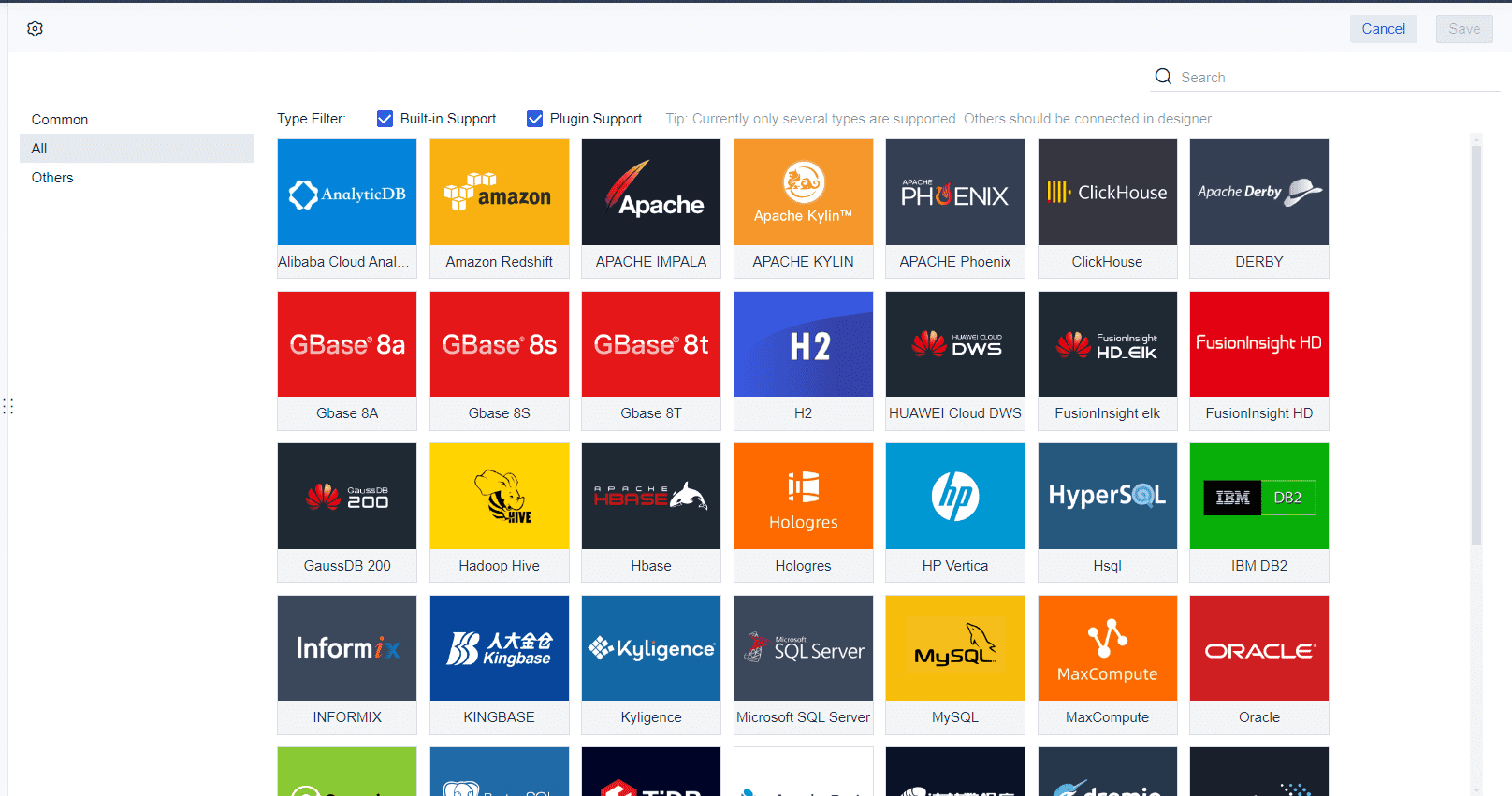

You need reliable data integration to make automated quality control effective. FineReport connects your automated inspection systems to databases like MySQL, Oracle, and SQL Server. You design web and app forms that write inspection results directly into your database. This process supports verification, saving, submission, review, and release, so you always have up-to-date quality data.

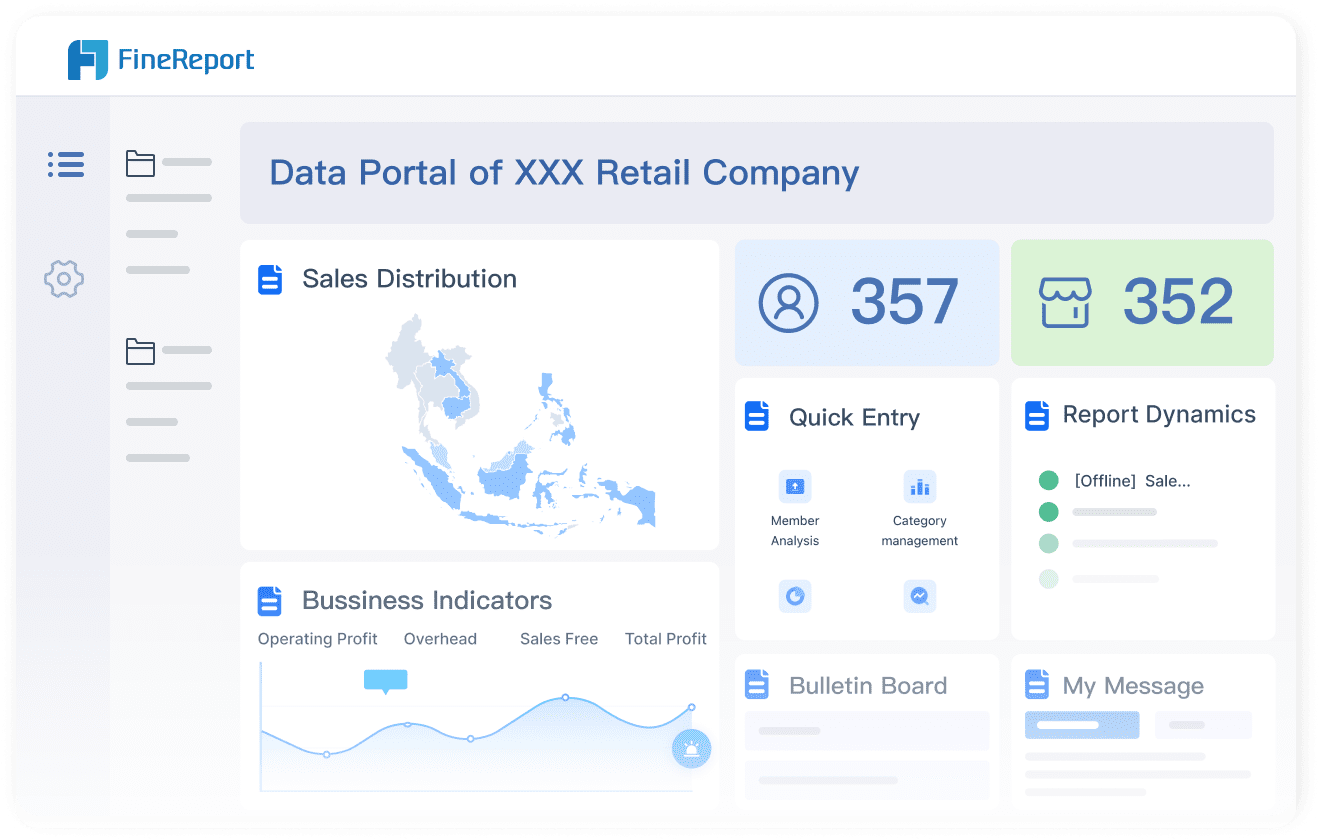

FineReport’s dashboard acts as your management cockpit. You monitor and analyze data in real time, using drill-down and multi-dimensional views. You access key quality indicators on any device, including mobile phones. This flexibility lets you respond quickly to issues and keep your production line efficient.

Tip: FineReport helps you collect and manage inspection data instantly, supporting real-time defect detection and quality control decisions.

You use real-time analytics to monitor production and catch problems early. Automated inspection systems send data to analytics platforms, which track quality metrics as products move through the line. You spot defects right away and take corrective action before issues spread.

Connected worker technology links IoT devices with your quality management system. You get instant updates on equipment and product quality, so you address issues as they happen. Machine learning algorithms help you predict problems and prevent downtime. You define clear quality metrics and use real-time analytics to detect anomalies and respond quickly.

Real-time analytics transforms your quality control from reactive to proactive, improving product reliability and operational efficiency.

You achieve higher accuracy and consistency when you use automated inspection in your quality control process. Automated systems use AI-powered cameras and sensors to check every product. These systems detect defects right away and reduce human error. You get reliable results because automated inspection does not get tired or distracted.

Automated inspection eliminates subjectivity. You no longer worry about inspectors missing defects or making mistakes. Machine learning algorithms estimate the severity of anomalies and help you prioritize corrective actions. You see improved data accuracy and fewer product recalls.

Automated inspection brings you improved inspection speed and lower costs. You process more products in less time because automated systems work around the clock. You do not need to add more workers to scale up production.

| Aspect | Manual Inspection Characteristics | Automated Inspection Characteristics |

|---|---|---|

| Speed | Slower, affected by human fatigue and variability | Fast, operates tirelessly without fatigue |

| Consistency | Inconsistent, defect detection rates vary (60-90%) | Highly consistent, defect detection often exceeds 99% |

| Scalability | Limited scalability due to labor intensity | Easily scalable to high-volume production |

| Labor Intensity | Labor-intensive, requires continuous human effort | Low labor intensity, reduces dependency on human inspectors |

You save money by reducing labor costs and cutting down on rework. Automated inspection systems lower error rates and help you avoid costly product recalls. Manufacturers report significant long-term savings and higher profitability after switching to automated quality inspection.

You make better decisions with automated quality control. Automated inspection systems collect real-time data and use advanced analytics to spot trends and root causes. You receive instant alerts when something goes wrong, so you can act fast.

Automated inspection shifts your quality control process from reactive to proactive. You prevent defects before they happen and support continuous improvement. You also streamline compliance reporting and keep your operations running smoothly.

You start the implementation of automated quality control by reviewing your current processes. First, identify where defects happen most often and see how well your current inspection works. Next, choose the right automated inspection technologies for your needs. You might use machine vision, sensors, or AI-powered analytics. Then, connect these automated systems with your existing ERP and MES platforms. This step lets you track defects and take action in real time. Train your team to work with the new automated tools and understand the reports they generate. Finally, monitor the performance of your automated inspection and adjust the system as you collect more data.

Tip: Use robotics for repetitive or dangerous tasks and sensors for real-time monitoring. This approach improves both safety and accuracy.

FineReport makes integrating automated systems easier. You can connect data from many sources, including different databases and inspection devices. FineReport lets you design flexible reports and dashboards that show key quality metrics. You view these dashboards on your computer or mobile device. Drill-down features help you analyze defects and trends quickly. You can enter data directly into reports, manage user permissions, and schedule automated report delivery. FineReport supports real-time monitoring, so you always have the latest information for decision-making.

| FineReport Feature | Benefit for Quality Control |

|---|---|

| Multi-data integration | Collects and combines data from all inspection points |

| Custom dashboards | Visualizes trends and defects in real time |

| Mobile access | Lets you check quality metrics anywhere |

| Scheduled reports | Delivers updates automatically to your team |

You achieve the best results by following proven steps. Define clear goals and key performance indicators before you begin. Assess your current workflow to find weak spots. Integrate automated inspection with your MES, ERP, and SCADA systems to avoid data silos. Standardize how you collect and report data for consistency. Train your team with hands-on workshops and provide ongoing support. Roll out the system in phases to reduce disruptions. Set up regular maintenance and updates. Use analytics to spot trends and improve your process over time. Avoid common mistakes like buying the wrong equipment or skipping team training. Good communication and clear project ownership help your implementation of automated quality control succeed.

You see automated inspection transforming manufacturing across many industries. AI-powered machine vision systems help you detect and classify defects in real time. These systems analyze thousands of images every minute, finding tiny flaws that human inspectors miss. You use automated quality control solutions in automotive, electronics, food and beverage, pharmaceuticals, and semiconductor production. These industries rely on automated inspection for high-speed, consistent quality inspection.

Automated inspection helps you reduce waste, improve throughput, and maintain high standards in every batch.

You can streamline your quality control process with FanRuan and FineReport. These automated quality control solutions connect your inspection devices, sensors, and databases. FineReport lets you design dashboards that visualize defect rates, scrap rates, and qualification rates. You monitor quality inspection data in real time and drill down to analyze trends or root causes. You use mobile dashboards to check quality metrics anywhere, supporting fast decision-making.

FineReport supports automated inspection by integrating with IoT sensors and machine vision systems. You collect inspection results instantly and use analytics to detect and classify defects. The platform enables you to set up alerts, schedule reports, and manage user permissions. You optimize your process by tracking quality inspection data and making adjustments based on real-time insights.

| Solution Feature | How You Benefit |

|---|---|

| Multi-source integration | Combines all inspection data |

| Custom dashboards | Visualizes trends and defect patterns |

| Real-time analytics | Enables quick response to issues |

| Mobile access | Lets you monitor quality anywhere |

You find automated quality control solutions in many real-world scenarios. Automotive manufacturers use automated inspection in the automotive industry to reduce scrap rates and improve adaptability. Electronics companies rely on automated inspection to boost first-pass yield and minimize rework. Healthcare organizations use automated inspection for accurate data entry and compliance. Food and beverage firms inspect produce quality and packaging with automated quality control solutions.

| Industry | Use Case Description | Benefits Highlighted |

|---|---|---|

| Automotive | Warranty claims, engine inspection, defect tracking | Faster processing, fewer errors |

| Manufacturing | Real-time defect detection, process optimization | Quicker issue resolution, less waste |

| Electronics | Solder fault detection, predictive analytics | Higher yield, reduced rework |

| Healthcare | Electronic health records, compliance automation | Improved accuracy, less manual effort |

| Pharmaceuticals | Regulatory submissions, packaging inspection | Ensures compliance, reduces errors |

You improve defect tracking and process optimization by using AI-powered computer vision, IoT sensors, and predictive analytics. These technologies help you detect and classify defects, automate quality inspection, and drive continuous improvement.

You now understand how automated quality control works and why it matters. You saw how automated systems improve accuracy, efficiency, and decision-making. You learned how FineReport helps you manage data and monitor quality in real time.

FineReport gives you powerful dashboards and analytics.

Future trends like AI and IoT will make quality control smarter. You can start exploring automated solutions to boost your own organization’s performance.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025