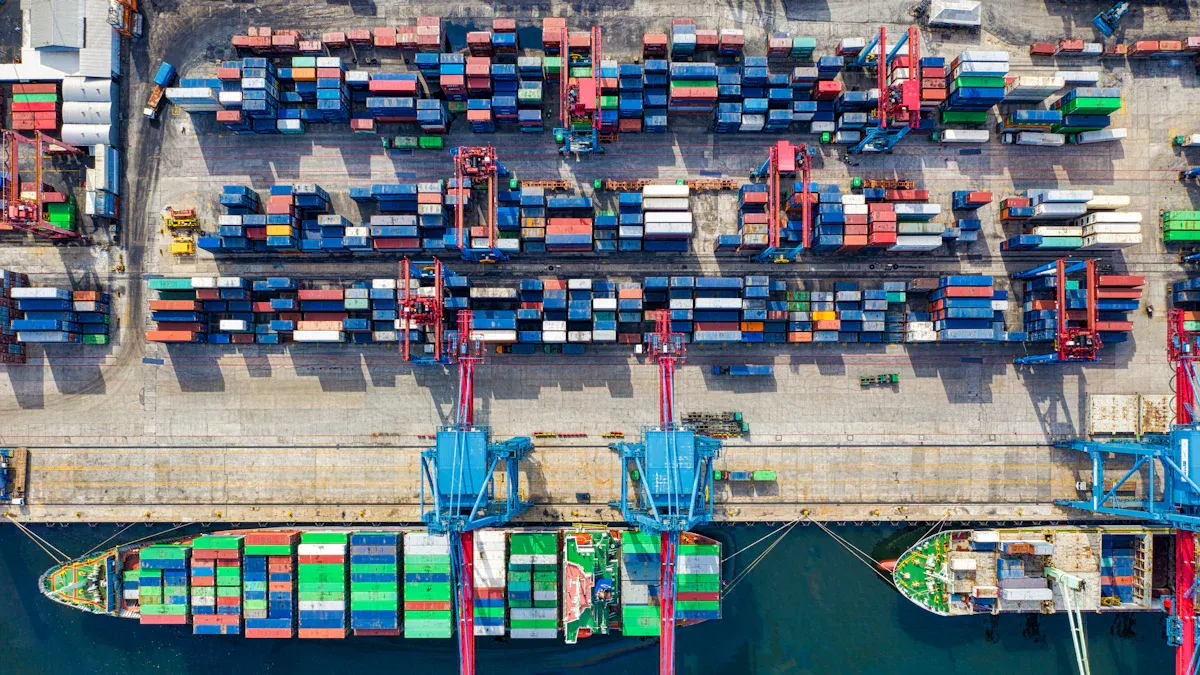

Supply chain analysis gives you a clear view of how your business moves products and information from suppliers to customers. When you use supply chain analysis, you spot inefficiencies and improve your supply chain management. In manufacturing, analysis helps you respond quickly to changes and avoid costly disruptions. Digital transformation now drives supply chain analysis by enhancing data connectivity and supporting analytics for smarter decisions. You benefit from data-driven supply chain analysis through real-time insights and actionable analytics. Many manufacturers face challenges with analytics and data skills, but tools like FineReport make analysis accessible. FineReport enables you to base your supply chain management on data-driven decisions, so you stay competitive.

Supply chain analysis gives you a structured way to evaluate how your business moves products, information, and finances from suppliers to customers. You use supply chain analysis to study operations and processes, aiming for improvement at every stage. This approach involves both strategic and operational perspectives. You model processes and measure performance to see how well your supply chain works and how it affects your bottom line.

Supply chain analytics helps you understand the flow of goods and information. You use analytics to identify bottlenecks, reduce costs, and improve efficiency. When you apply supply chain analytics, you gain insights that support better decision-making and help you respond to changes in the market.

Global manufacturers now adopt supply chain analysis to address new challenges. You see trends like reshoring and nearshoring, which move operations closer to home to cut costs and avoid tariffs. Many organizations invest in generative AI for demand forecasting and risk management. Sustainability also becomes a major focus, with companies increasing efforts to make their supply chains more environmentally friendly.

You need to understand the key components of supply chain analytics to build a strong analysis framework. Academic literature identifies several essential elements that shape how supply chains operate and adapt to challenges.

The key components of supply chain analytics include integration, operational factors, strategic planning, and relational dynamics. These elements help you understand how supply chains respond to disruptions, such as the COVID-19 crisis.

Supply chain analysis frameworks also address risk management and mitigation. You follow a structured process:

You use supply chain analytics to identify risks, assess their impact, and implement strategies like diversification and redundancy. Continuous monitoring helps you adjust your approach as needed.

Different industries focus on unique aspects of supply chain analysis. The table below shows how retail and manufacturing prioritize their strategies:

| Industry | Key Focus Areas | Operational Strategies |

|---|---|---|

| Retail | Customer interaction, Inventory management | Emphasizes demand forecasting and order fulfillment |

| Manufacturing | Production efficiency, Supplier relationships | Focuses on procurement strategies and supplier collaboration |

You see that retail relies on demand forecasting, inventory management, marketing, and order fulfillment. Manufacturing emphasizes production efficiency and supplier relationships, using procurement strategies and collaboration to optimize performance.

Supply chain analytics gives you the tools to analyze these components. You use analytics to track performance, manage risks, and adapt to changing conditions. When you understand the key components of supply chain analytics, you build a resilient and efficient supply chain that supports your business goals.

You need a clear process to make supply chain analysis effective. Most supply chain management textbooks describe five main steps that guide your analysis. Each step helps you understand and improve your supply chain analytics.

Supply chain analysis uses these steps to break down complex operations. You apply supply chain analytics at each stage to identify bottlenecks, reduce costs, and boost efficiency. When you follow this process, you gain a structured approach to analysis and make better decisions.

Tip: Use supply chain analytics to monitor each step. You will spot issues early and respond quickly.

You measure the success of your supply chain analysis using performance metrics and benchmarking. Organizations rely on standardized metrics to evaluate supply chain analytics initiatives. You compare your results against best-in-class companies to find areas for improvement.

Common metrics in supply chain analysis include:

You collect data and use advanced analytics to turn information into actionable insights. Supply chain analytics help you track performance, set benchmarks, and drive continuous improvement. When you use analysis and analytics together, you build a resilient supply chain that adapts to change.

Note: Regular performance evaluation in supply chain analysis ensures your analytics stay relevant and effective.

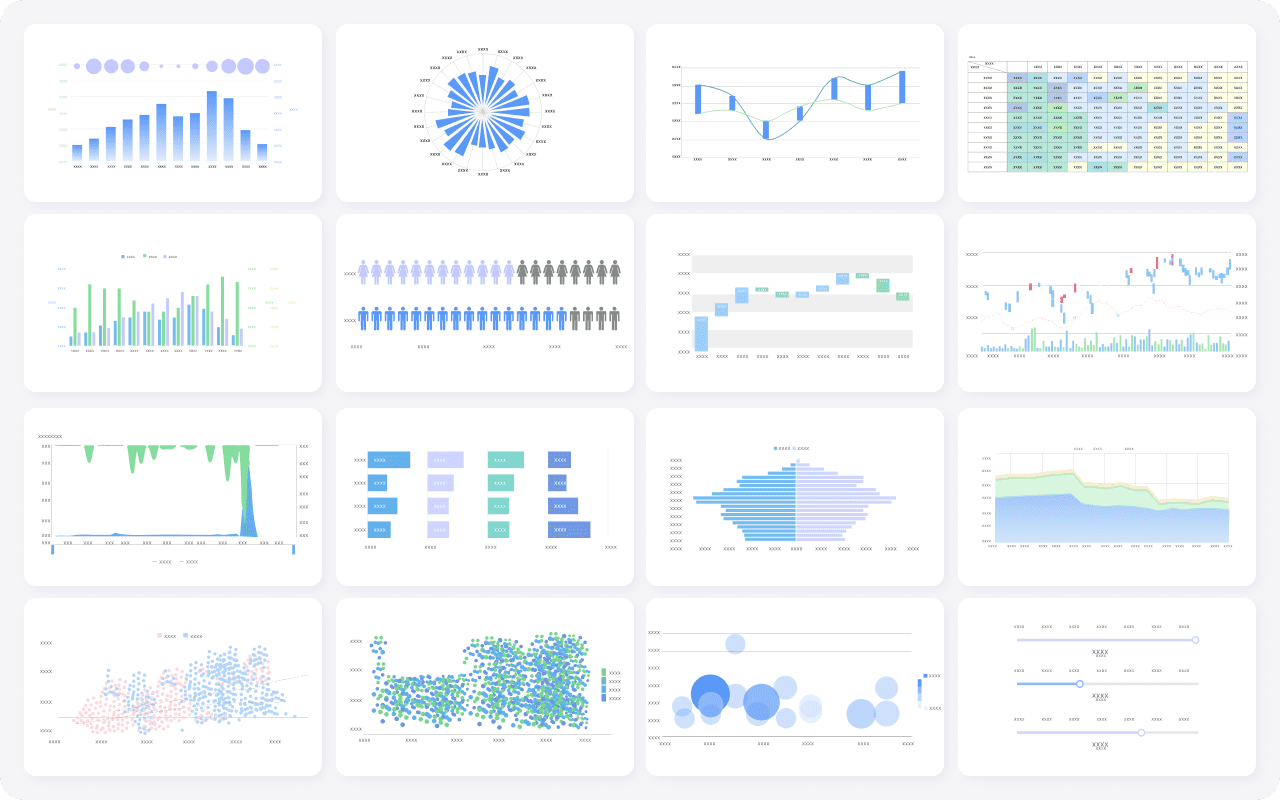

You have many options when choosing supply chain analytics tools for your business. Large enterprises rely on platforms that deliver real-time insights and support efficient supply chain management. Some of the leading supply chain analytics tools include:

Digital transformation drives the adoption of these tools. You benefit from improved efficiency, visibility, and data-driven decision-making. Advanced technologies like AI and IoT help you optimize inventory and forecast demand. Real-time tracking gives you immediate insights, which improves operational agility and profitability.

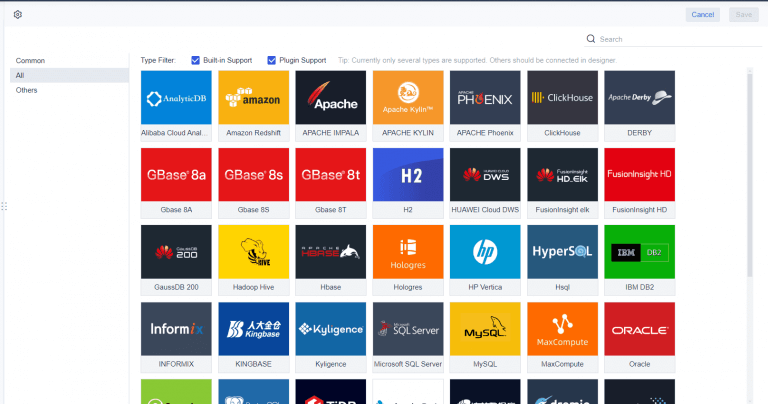

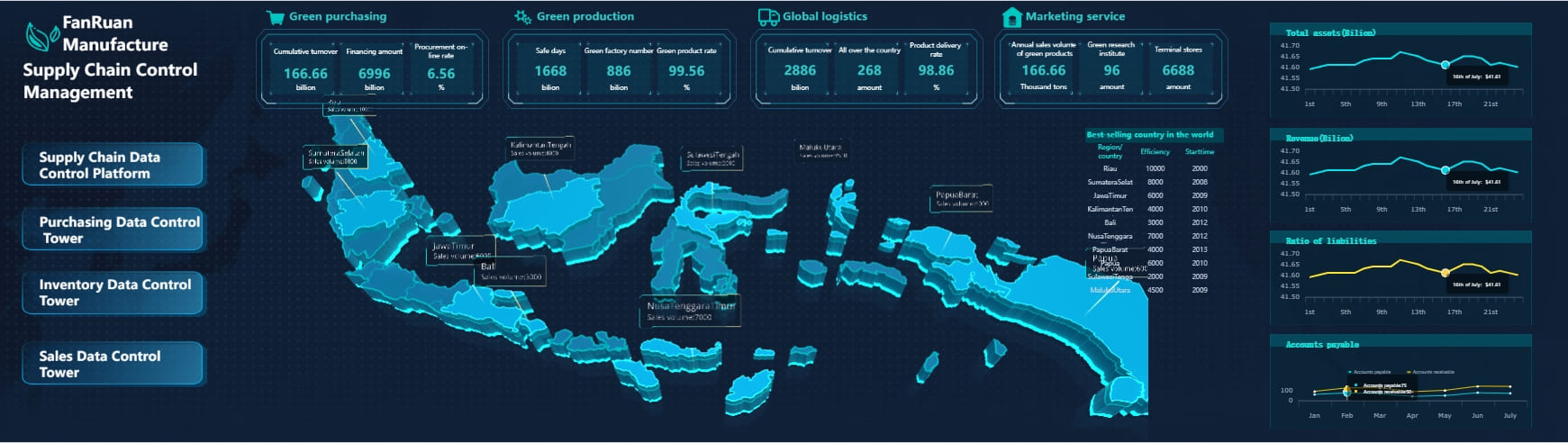

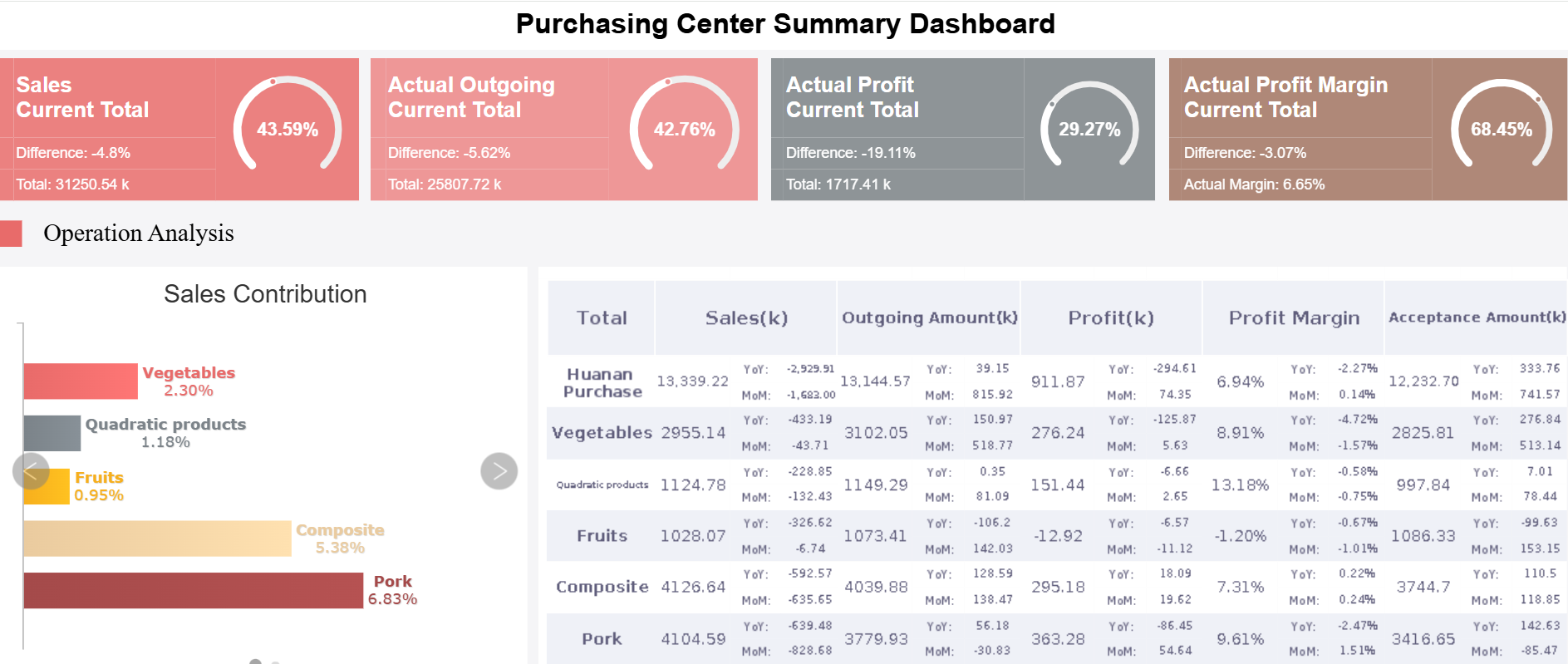

FineReport stands out as a supply chain analytics solution that supports your analysis needs. You use FineReport to connect diverse data sources, process information, and visualize results. FineReport enhances efficiency by at least 50% compared to traditional methods. You receive real-time feedback and validate outcomes instantly. FineReport integrates with platforms such as AWS, Google Cloud, Snowflake, and Databricks, making it a flexible choice for supply chain management.

You need strong data integration and visualization features to make supply chain analysis effective. Most supply chain analytics platforms connect to both internal and external data sources. You can see examples in the table below:

| Data Source Type | Examples |

|---|---|

| Internal Data Sources | POS, supplier, demand, production data |

| External Data Sources | Marketplaces, weather, demographics, competitive movements |

| Internal Systems | ERP, WMS, TMS, SCM, CRM |

| External Sources | Supplier databases, third-party logistics, IoT devices |

FineReport supports seamless integration with these sources. You use FineReport to unify data from ERP, CRM, and external systems, which improves your supply chain management analysis. FineReport provides interactive dashboards for real-time monitoring and analysis. You can drill through metrics for deeper insights and use component jumps for easy navigation. The table below highlights key visualization features:

| Feature | Description |

|---|---|

| Interactive Dashboards | Real-time monitoring and analysis of supply chain activities, integrating data from various sources. |

| Drill-Through | Click on metrics for detailed performance data and supplier information. |

| Component Jump | Navigate dashboards easily and access different data components. |

Self-service dashboards empower you to access and analyze data independently. You identify inefficiencies, optimize resources, and reduce costs. Real-time data improves visibility and transparency, helping you respond quickly to disruptions. You build a data-driven culture where employees at all levels make informed decisions using supply chain analytics.

You gain many advantages when you use supply chain analysis in your business. This approach helps you understand your supply chain performance and make better decisions. The benefits of supply chain analysis reach across cost, speed, and visibility. You can see the main benefits in the table below:

| Benefit | Description |

|---|---|

| Cost Reduction | You identify cost-saving opportunities by monitoring metrics like inventory turnover. |

| Improved Delivery Times | You use order cycle time and on-time delivery rates to find bottlenecks and increase speed. |

| Enhanced Visibility | You monitor KPIs regularly to get a full view of supply chain performance. |

| Operational Efficiency | You streamline operations, reduce delays, and achieve faster turnaround times. |

Supply chain analytics drive these improvements. Companies that invest in analytics often report cost reductions between 15% and 40%. Some manufacturers have cut inventory costs by as much as $1 billion. Retailers have saved up to 27% on shipping costs. You also see faster cash flow and lower emissions in some industries. These measurable results show the real benefits of supply chain analysis and analytics for your operations.

Note: Optimization through supply chain analysis supports better supply chain management and helps you stay competitive.

You may face several challenges when you implement supply chain analysis. These issues can slow down your progress and affect your supply chain management. The most common challenges include:

Supply chain analytics can help you address these challenges, but you need to prepare for them. Many organizations overcome these obstacles by automating processes, partnering with industry peers, and working to achieve end-to-end visibility. You should also involve all stakeholders, set clear goals, and provide training to ensure successful analysis and analytics adoption.

Tip: Regularly review your supply chain analysis process to identify new risks and keep your operations running smoothly.

You need a clear roadmap when you ask how to conduct a supply chain analysis. This process helps you understand your supply chain and make informed decisions. You can follow these practical steps to ensure your supply chain analysis delivers actionable results:

Tip: Prepare your data before starting supply chain analysis. Ensure you have enough data to reflect your operations accurately. Clean your data to remove errors and inconsistencies. Include all necessary components to avoid incomplete analysis.

FineReport supports each step of supply chain analysis. You connect to multiple data sources, including ERP, CRM, and external systems. FineReport helps you prepare and process data, create self-service datasets, and build interactive dashboards. You can collaborate with your team by sharing dashboards and reports securely.

You can improve your supply chain analysis by following proven strategies and best practices. These tips help you integrate supply chain analytics into your business and maximize results, especially in manufacturing.

| Best Practice | Description |

|---|---|

| Innovation is King | Use automation, AI, and machine learning to enhance supply chain analytics and processes. |

| Commitment to Reduction in Non-Value-Added Tasks | Automate tasks that do not add value using predictive analytics and AI. |

| Invest Only in Needed Inventory | Optimize inventory by implementing as-needed systems to avoid overstocking. |

| End-to-End Visibility Access | Integrate systems for full visibility across your supply chain, enabling quick decisions. |

You should foster collaboration when conducting supply chain analysis. Leverage technology to automate processes and improve data access. Enhance communication with suppliers to strengthen relationships and performance. Build strong partnerships by aligning goals and sharing insights.

You can use these strategies to integrate supply chain analytics into your existing processes:

FineReport makes supply chain analysis easier by providing tools for data preparation, dashboard creation, and team collaboration. You can connect to diverse data sources, clean and process your data, and visualize key metrics. FineReport's self-service dashboards empower you to analyze supply chain performance and share insights across your organization.

Note: Successful supply chain analysis depends on accurate data, strong collaboration, and continuous improvement. Use analytics to drive innovation and efficiency in your supply chain.

Supply chain analysis gives you the power to improve efficiency and boost competitiveness. You see real value when you optimize processes, reduce costs, and meet customer expectations.

Advanced analytics tools like FineReport help you turn data into actionable insights. You forecast demand, manage inventory, and identify risks before they become problems. Companies use these tools to achieve strategic value and operational improvement. Explore supply chain analytics to strengthen your decision-making and drive your business forward.

What is Supply Chain Risk Management Process and How It Work

Supply Chain Risk Explained and Why it Matters Now

What is Supply Chain Visibility and Why Does It Matter

Supply Chain Analytics Explained and Its Importance

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025