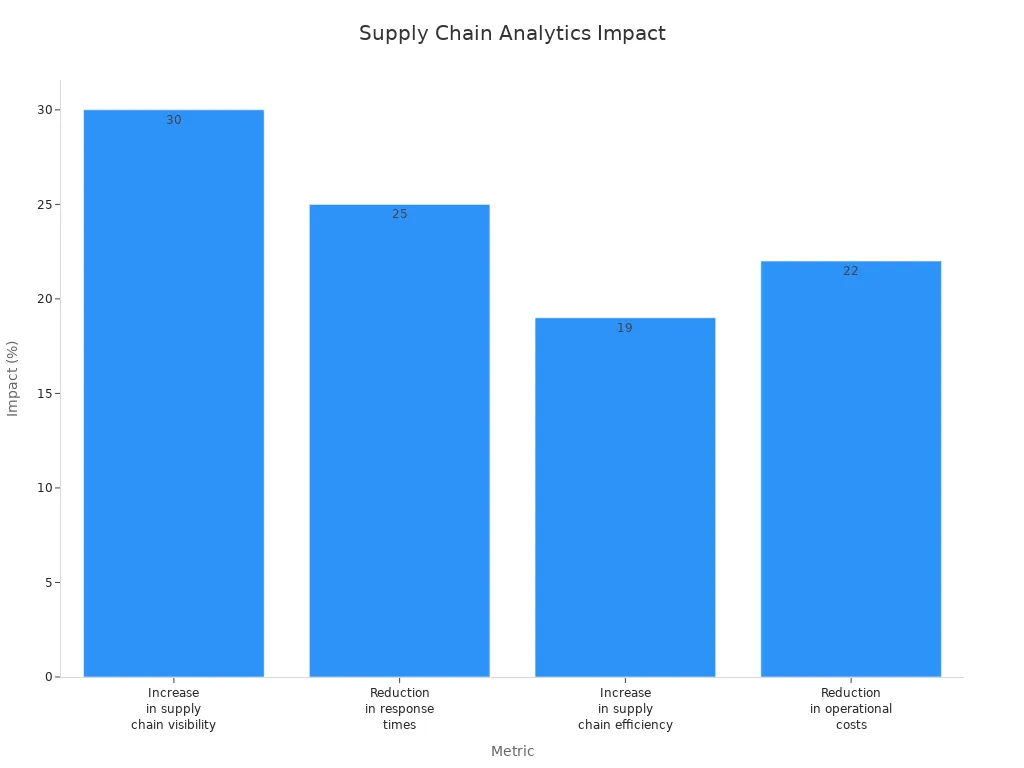

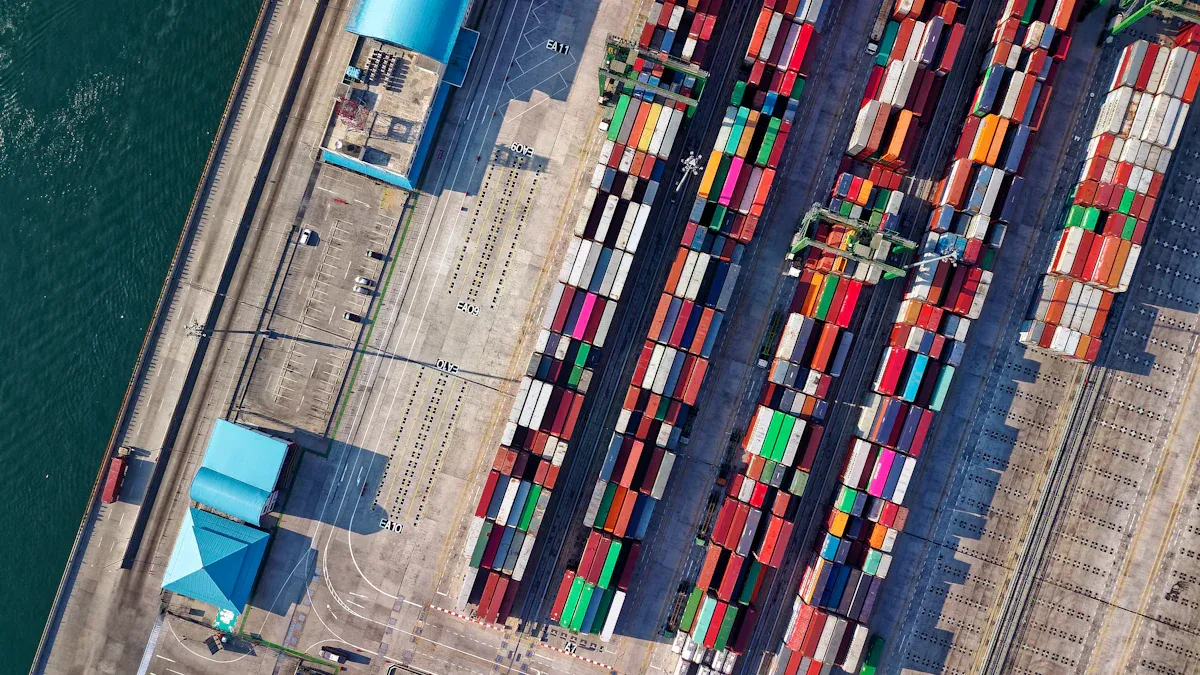

Supply chain analytics gives you the power to make data-driven decisions that boost efficiency and resilience. Businesses worldwide now see real results from this approach.

Companies using these tools report a 22% drop in operational costs and a 19% rise in efficiency.

You encounter supply chain analytics every time you see a company improve its delivery speed or reduce costs. Supply chain analytics refers to the processes organizations use to extract insights and value from large volumes of data related to procurement, processing, and distribution of goods. It stands as a core part of supply chain management.

Supply chain data analytics relies on several key components:

You need to integrate and manage data from many sources, such as procurement and distribution. Advanced analytical techniques, including machine learning and predictive analytics, help you optimize operations. Real-time monitoring and reporting allow you to track key performance indicators and respond quickly to disruptions.

Supply chain data analytics plays a vital role in helping you make better decisions. You use data analytics to improve planning and forecasting. By analyzing large data sets, you gain valuable insights that guide your choices. Predictive analytics lets you anticipate demand and adjust your supply chain accordingly. Accurate forecasts help you avoid stockouts and overstocking, making your supply chain more agile.

You can identify areas for cost reduction through supply chain data analytics. This leads to significant savings and lower operational expenses. Early detection of risks and disruptions allows you to create contingency plans, boosting your supply chain’s resilience.

You have access to a wealth of existing data. Supply chain analytics enables you to optimize inventory and transportation costs. High-quality data must be accurate, complete, timely, consistent, and synchronized.

You cannot ignore the importance of supply chain analytics if you want to succeed in today’s competitive market. Supply chain analytics helps you make faster and smarter decisions about your operations. It delivers lasting value for your business.

Ultimately, supply chain analytics plays an important role in helping inventory-based businesses navigate the uncertainties of today’s business landscape, where disruptions can occur at any time.

Metrics from supply chain analytics help you meet customer expectations. Any disruption in the supply chain can hurt the customer experience and drive them to competitors. You use supply chain analysis to monitor performance and ensure smooth operations.

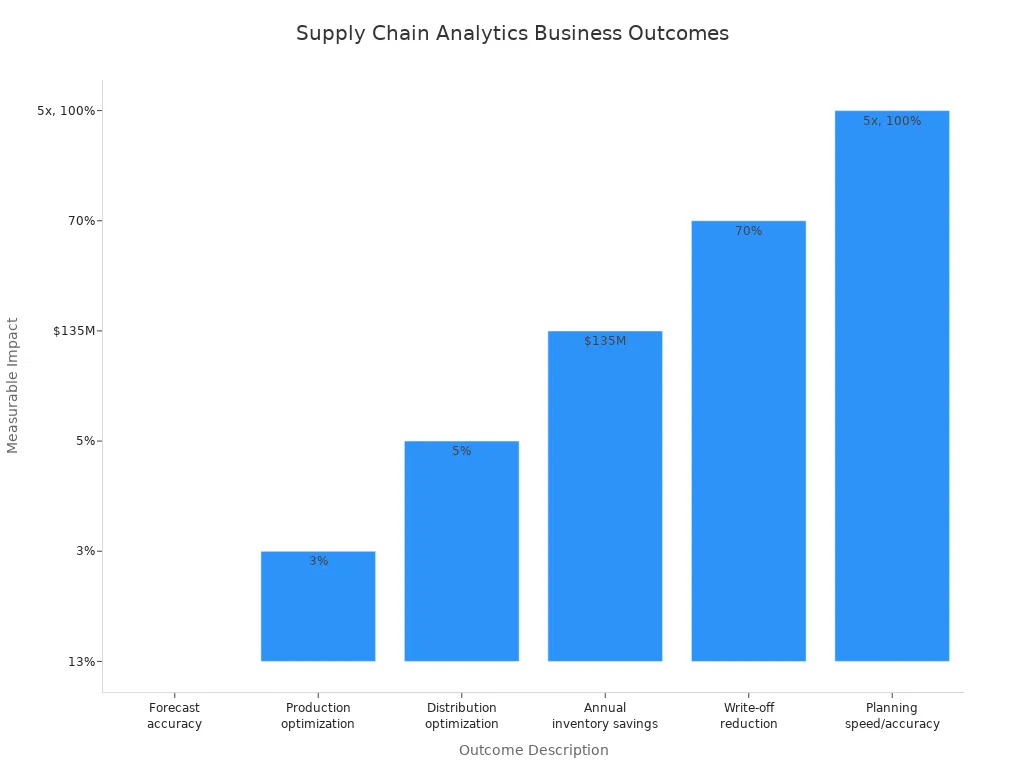

The measurable outcomes of supply chain analytics speak for themselves:

| Outcome Description | Measurable Impact |

|---|---|

| Increased forecast accuracy for key SKUs | Up by 13% |

| Savings in production optimization | 3% savings |

| Savings in distribution optimization | 5% savings |

| Recurring annual inventory savings | $135 million |

| Reduction in write-offs | 70% reduction |

| Speed and accuracy of planning-related tasks | 5 times faster, 100% accuracy |

You see real improvements in forecast accuracy, cost savings, and planning speed. Supply chain data analytics helps you meet customer needs and stay ahead of competitors. The importance of supply chain analytics continues to grow as businesses face new challenges and opportunities.

Supply chain analytics includes several types that help you understand, diagnose, and forecast supply chain performance. You use these analytics to make better decisions and improve your operations. Each type serves a unique purpose and provides different insights.

| Type of Analytics | Description | Examples |

|---|---|---|

| Descriptive analytics | Understand what has happened in the supply chain. | Inventory levels over time, order fulfillment rates. |

| Diagnostic analytics | Understand why something happened. | Root-cause analysis of delivery delays, identifying bottlenecks. |

| Predictive analytics | Forecast what's likely to happen. | Demand forecasting, predicting stockouts. |

You start with descriptive analytics to answer the question, "What happened?" This type helps you analyze historical data from your supply chain. You can track inventory levels, order accuracy, and delivery times over months or years. Descriptive analytics lets you spot trends and seasonal changes in customer behavior. You also identify bottlenecks and inefficiencies by reviewing supplier performance and transportation data. When you use descriptive analytics, you gain a clear picture of your supply chain’s past performance.

Tip: Descriptive analytics provides the foundation for deeper analysis. You need accurate historical data to move forward with more advanced techniques.

After you know what happened, you use diagnostic analytics to find out why it happened. This type helps you identify the reasons behind operational issues and inefficiencies. You can analyze the causes of low inventory levels or slow supplier deliveries. Diagnostic analytics lets you pinpoint the origin of problems, such as delays caused by external events like severe flooding. You use this analysis to understand disruptions and develop solutions to prevent them in the future. By examining errors and delays, you improve your supply chain processes.

Predictive analytics helps you look ahead and anticipate what might happen in your supply chain. You use predictive models to forecast demand, predict stockouts, and identify potential risks. These models rely on historical data and machine learning to spot patterns and trends. Predictive analytics enables you to optimize inventory by analyzing market trends and maintaining the right stock levels. You also improve supplier risk management by identifying vendors at risk of non-compliance or delays. Predictive models enhance transportation logistics by forecasting disruptions and allowing smarter planning.

Predictive analytics gives you the power to anticipate problems before they occur. You can develop strategies to mitigate risks and keep your supply chain running smoothly.

Prescriptive analytics takes supply chain analytics to the next level. You do not just predict what might happen—you receive recommendations on what actions to take. Prescriptive analytics uses advanced algorithms and optimization models to suggest the best decisions for your supply chain. You can simulate different scenarios and choose the most effective strategy.

You often use prescriptive analytics in several key areas of supply chain analytics. The table below shows common applications and their benefits:

| Application | Description | Benefits |

|---|---|---|

| Supply Chain Network Design | Determines the supply chain’s footprint and product flow. | Cost savings up to 30%, improved resilience and agility, better service levels. |

| Sales & Operations Planning | Aligns supply and demand, resulting in sales, production, and inventory plans. | 10-40% improvement in on-time delivery, lower transport costs, up to 70% lower inventory. |

| Sales & Operations Execution | Focuses on more frequent planning for rapid response. | More resilient planning, better handling of unexpected events, higher customer satisfaction. |

| Inventory Optimization | Balances demand and supply uncertainty while maximizing service and minimizing costs. | 20% reduction in out-of-stock occurrences, lower costs, improved planning efficiency. |

| Warehouse Optimization | Addresses the complexities of running a warehouse, especially with last-minute changes. | Enhanced operational efficiency through mathematical optimization tools. |

With prescriptive analytics, you can optimize your supply chain network, improve planning, and reduce costs. You gain the ability to make decisions that increase efficiency and customer satisfaction. Supply chain analytics becomes a powerful tool for continuous improvement.

Cognitive analytics represents the most advanced stage of supply chain analytics. You use artificial intelligence and machine learning to analyze complex data and make decisions in real time. Cognitive analytics learns from new data and adapts to changing conditions.

You see cognitive analytics in action across leading companies:

According to industry research, supply chains that use cognitive analytics improve demand forecasting accuracy by 35% and reduce supply disruptions by 50%. Companies investing in AI-driven supply chain analytics also see a 35% boost in operational efficiency and a 50% reduction in order processing time. You gain a smarter, more agile supply chain that adapts quickly to new challenges.

You gain a major advantage when you use supply chain analytics for forecasting and planning. Advanced analytics tools help you achieve better forecasting accuracy and supply chain visibility. You see patterns in historical data and predict future trends. This process supports effective planning and helps you avoid costly mistakes.

Supply chain optimization relies on accurate forecasts. You can plan production schedules, manage inventory, and meet customer expectations with confidence.

Supply chain analytics drives cost reduction and efficiency gains across your operations. You use digital tools and optimization software to configure logistics and streamline processes.

Companies like Walmart have used supply chain analytics to identify inefficiencies and optimize inventory management. By predicting customer demand, Walmart improved product availability and reduced stockouts. You can follow a structured approach:

Supply chain optimization helps you cut costs and boost productivity. You see faster order fulfillment and lower operational expenses.

You strengthen risk management when you apply supply chain analytics. The use of advanced technologies increases supply chain visibility and resilience. You monitor operations in real time with IoT devices. AI and machine learning algorithms analyze data to predict risks and optimize your supply chain. Automation reduces human error and operates safely in hazardous conditions. Regular risk assessments help you adapt to market changes and identify new threats.

| Improvement Type | Description |

|---|---|

| Advanced Technologies | New methods to enhance supply chain analytics and visibility. |

| Real-time Monitoring | Use of IoT devices for tracking and monitoring throughout the supply chain. |

| Predictive Analytics | AI and ML algorithms analyze data to predict risks and optimize operations. |

| Automation | Reduces human error and operates in hazardous conditions, lowering risk. |

| Regular Risk Assessments | Frequent evaluations to identify new risks and adapt to market changes. |

You build a resilient supply chain that can handle disruptions and protect your business.

You want your customers to feel satisfied every time they interact with your business. Supply chain analytics helps you achieve this goal by giving you deeper insights into what your customers want and need. When you understand customer preferences, you can deliver better service and meet expectations more consistently.

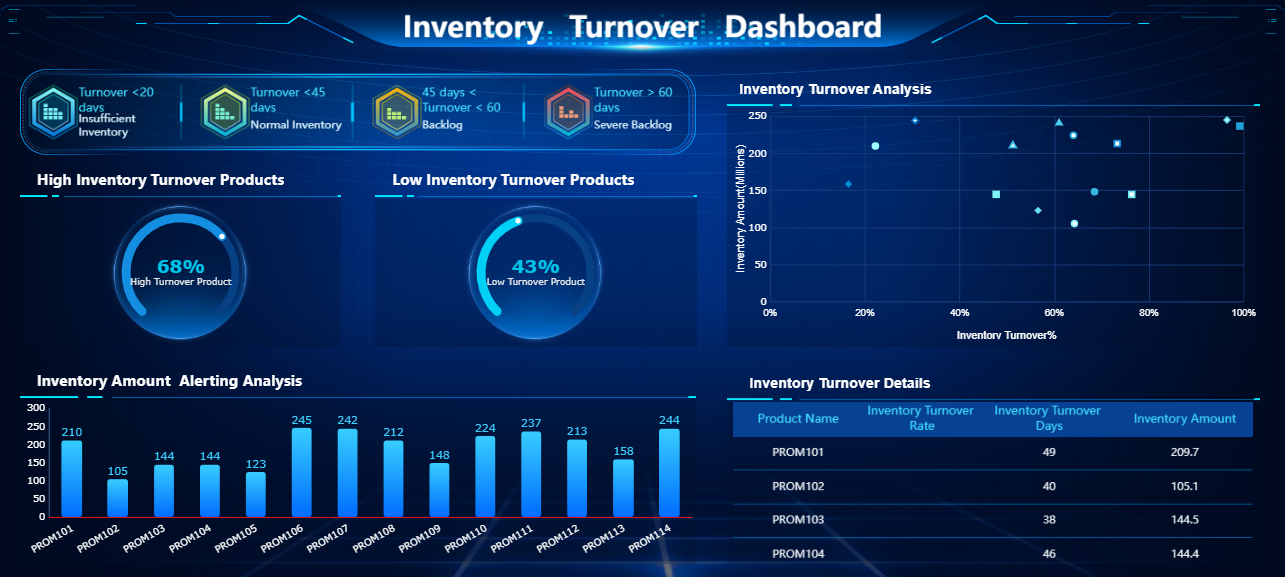

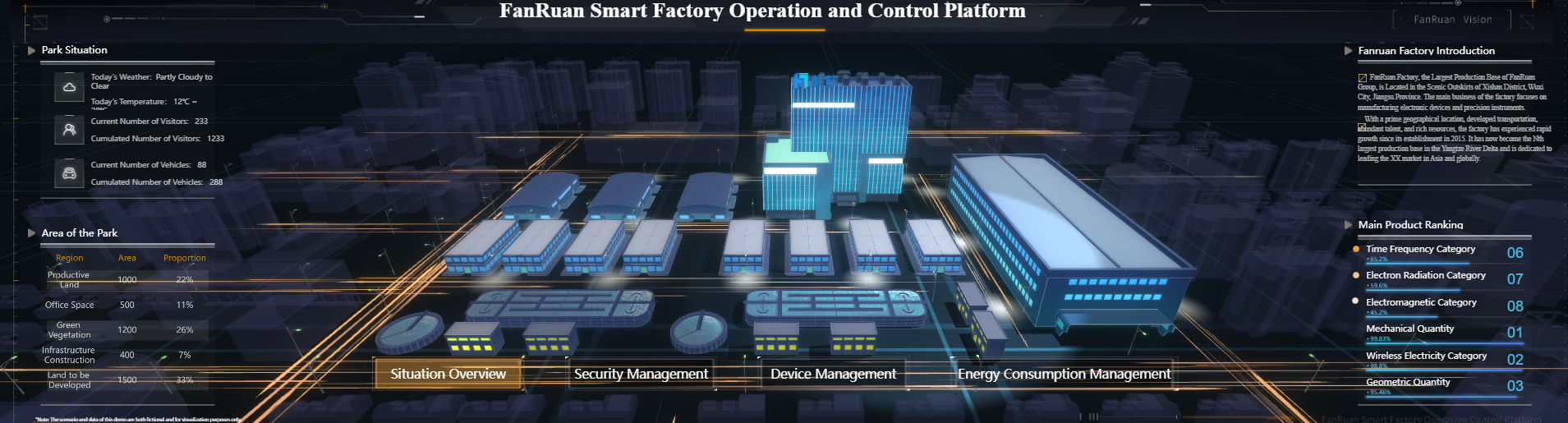

Real-time dashboards play a key role in improving customer experience. You can monitor orders, shipments, and inventory as they happen. This visibility helps you solve problems before they affect your customers. When you use real-time dashboards, you keep your team informed and ready to act. Your customers benefit from faster deliveries and fewer mistakes.

Supply chain analytics also helps you reduce delays and prevent stockouts. You can track every step of the process, from supplier to customer. This level of control leads to higher satisfaction scores and stronger loyalty. When you use data to guide your decisions, you build a reputation for reliability and quality.

You can see the power of supply chain analytics in action with FineReport. FineReport gives you the tools to connect, analyze, and visualize your supply chain data from multiple sources. You can create real-time dashboards that show key performance indicators, inventory levels, and supplier performance all in one place.

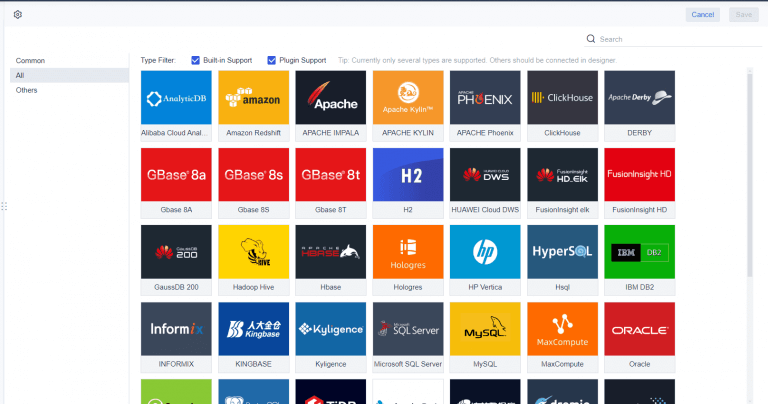

With FineReport, you do not need advanced technical skills. The drag-and-drop interface lets you build custom dashboards quickly. You can track shipments, monitor supplier reliability, and spot potential disruptions before they become problems. FineReport supports over 60 data connectors, so you can bring together information from databases, cloud platforms, and APIs.

FineReport's real-time dashboards help you make faster decisions. You can share insights across your team, set up alerts for critical issues, and ensure everyone stays informed. This leads to better planning, fewer errors, and a smoother customer experience. FineReport empowers you to turn raw data into actionable insights, making your supply chain more agile and responsive.

You see a clear contrast between traditional supply chains and those powered by supply chain analytics. Traditional methods often rely on guesswork and manual tracking. You might use spreadsheets to monitor suppliers and react to problems only after they occur. Analytics-driven supply chains use data to predict needs and optimize every step. You gain real-time insights and can spot disruptions before they affect your business.

Here is a table that highlights the main differences:

| Traditional Method | Analytics-Driven Method |

|---|---|

| Relying on guesswork for order timing | Using data to predict when parts will be needed, preventing shortages |

| Tracking suppliers manually | Analyzing supplier performance in real-time, optimizing procurement decisions |

| Limited visibility of supply chain status | Real-time insights on supply chain performance, identifying potential disruptions early |

| No optimization of procurement process | Data-driven insights help adjust procurement strategies, improving cost efficiency and reducing waste |

| Reactive approach to problems | Proactive problem-solving by identifying trends and potential issues before they happen |

The shift to analytics-driven supply chain management changes your strategy. You move from reacting to problems to anticipating and preventing them.

When you integrate supply chain analytics, you add measurable value to your operations. You can anticipate demand and plan resources more effectively. Data analysis helps you maintain optimal inventory levels, which reduces costs from overstocking or running out of stock. You identify risks early and take action to minimize disruptions. Analytics tools turn fragmented data into clear insights, making your decisions faster and more accurate.

| Benefit of Analytics | Description |

|---|---|

| Anticipate Demand | Predictive analytics helps companies forecast demand fluctuations, allowing for better planning and resource allocation. |

| Optimize Inventory | By analyzing data, companies can maintain optimal inventory levels, reducing costs associated with overstocking or understocking. |

| Mitigate Risks | Early identification of potential risks enables proactive measures, minimizing disruptions in the supply chain. |

| Improve Efficiency | Analytics tools convert fragmented data into actionable insights, enhancing decision-making processes. |

You see improvements in planning, efficiency, and risk management when you use supply chain analytics.

Countries with advanced analytics capabilities, such as China, Germany, Japan, Korea, and the USA, show better performance in predicting supply chain relationships. Local models that use large datasets outperform those that rely on shared information. For example, China and Japan excel in predicting relationships like supplies_to and made_by. These results demonstrate how analytics-driven supply chains deliver stronger outcomes than traditional approaches.

You can achieve similar results by adopting analytics tools like FineReport. FineReport helps you connect data sources, analyze supplier performance, and visualize your supply chain in real time. This empowers you to make smarter decisions and stay ahead in a competitive market.

You may face several obstacles when you try to adopt supply chain analytics. Many organizations struggle with lengthy ROI processes and stakeholder resistance. You might see a need for comprehensive training and limited supply chain analytics skills among your team. Data integration challenges often slow progress. Some businesses still rely on Excel, which limits advanced analysis. Data quality issues can affect your results. High costs for analytics tools also present a hurdle.

You can overcome these barriers by identifying all relevant stakeholders, setting a clear timeline, and communicating the project’s value and goals. Be upfront about costs and resources, explain how the investment will provide ROI, define stakeholder investment, and solicit feedback to improve your plan.

You can address these challenges with proven strategies. Start by collecting and integrating data from various sources into a centralized system. Invest in advanced analytics tools and technologies to unlock the full potential of your supply chain data. Staff training is essential; equip your team with the skills needed for effective analytics use.

You should focus on data accuracy and quality. Integration issues require careful planning. Resistance to change can be managed by building a data-first culture and showing quick wins. Cloud-based analytics platforms help you manage costs, letting you pay only for what you use. Regular monitoring and collaboration among stakeholders ensure your analytics models stay relevant. Design your solutions to scale as your business grows.

You can begin your supply chain analytics journey with FineReport in a few simple steps. First, create an analysis subject that matches your business needs. Next, upload your supply chain data from different sources. FineReport supports real-time analytics, so you can analyze up-to-date information and spot trends quickly. Use the platform to explore and visualize your data. Share your findings and collaborate with your team to drive better decisions.

FineReport makes it easy for you to connect, process, and visualize supply chain data. You gain the ability to make informed decisions and improve your supply chain performance.

You need supply chain analytics to succeed in 2025 and beyond. You gain smarter decisions, greater agility, and a stronger competitive edge. The future will focus on resilience, advanced technology, and sustainability:

| Trend | Description |

|---|---|

| Resilience | Companies will diversify suppliers and adopt risk management strategies. |

| Advanced Tech | AI will improve forecasting and inventory management. |

| Sustainability | Eco-friendly practices will shape supply chain strategies. |

Start using advanced tools like FineReport to unlock real-time insights, automate data quality, and support your digital transformation.

What is Supply Chain Risk Management Process and How It Work

Supply Chain Risk Explained and Why it Matters Now

What is Supply Chain Visibility and Why Does It Matter

What is Predictive Analytics in Supply Chain Management

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025