Production monitoring gives you the ability to track, analyze, and improve every stage of manufacturing. You use product monitoring to collect real-time data from machines, sensors, and operators across the production floor. This approach delivers instant visibility, helping you detect issues and optimize production efficiency. Real-time monitoring enables predictive maintenance, immediate response to problems, and quality product monitoring. With advanced tools like FanRuan and FineReport, you streamline production, boost quality, and maintain control over every aspect of manufacturing.

When you set up production monitoring systems in your facility, you rely on several essential components to track and improve your manufacturing processes. These systems use a combination of hardware and software to give you a complete view of your production performance.

Tip: A robust production monitoring system adapts as your operations grow. You can scale up by adding more sensors or integrating with other platforms like MES or ERP.

Production monitoring systems depend on real-time data collection to provide accurate, up-to-date information about your manufacturing processes. Sensors and IoT devices play a critical role in this process. They gather data on temperature, vibration, pressure, humidity, and more. This information flows into your centralized monitoring system, where you can view it instantly.

You use several methods to collect and analyze production data:

For analysis, you apply both statistical and qualitative techniques:

Note: Secure storage, access control, and encryption protect your production data throughout its lifecycle.

Once your production monitoring system collects and analyzes data, you need to turn insights into action. Reporting tools present production metrics in clear dashboards and reports, making it easy for you to spot trends and respond quickly.

You take different actions based on the level of your organization:

| Organizational Level | Time Frame | Information Type | Common Actions Taken |

|---|---|---|---|

| Operational | Real-time to days | Detailed, granular | Operators respond to downtime, small stops, and quality issues in real time. |

| Tactical | Days to weeks | Comparative, trended | Managers launch improvement projects and coach staff to boost production performance. |

| Strategic | Weeks to months | Rolled-up, trended | Executives set objectives and allocate resources based on long-term production trends. |

You use these reports to:

Remember: The value of production monitoring systems comes from acting on the insights you gain. When you respond quickly to production data, you drive efficiency, improve quality, and support process optimization.

You can transform your manufacturing processes by adopting automated production monitoring. Traditional monitoring relies on manual data collection and delayed reporting, which often leads to operational blind spots and slow response times. Automated production monitoring uses direct equipment connectivity, IIoT sensors, and edge computing to provide immediate visibility into your production. This approach reduces manual intervention, as sensors and software handle data collection, analysis, and reporting. You receive instant alerts for anomalies, and predictive maintenance becomes possible. Automated systems also improve worker safety by limiting exposure to hazardous environments and reducing repetitive manual tasks. With these technologies, you shift from reactive to proactive management, allowing you to anticipate problems and make quick adjustments on the shop floor.

Real-time production monitoring delivers measurable benefits across your manufacturing operations:

Tip: Real-time monitoring empowers you to continuously optimize your production monitoring system, supporting ongoing improvements in efficiency and quality.

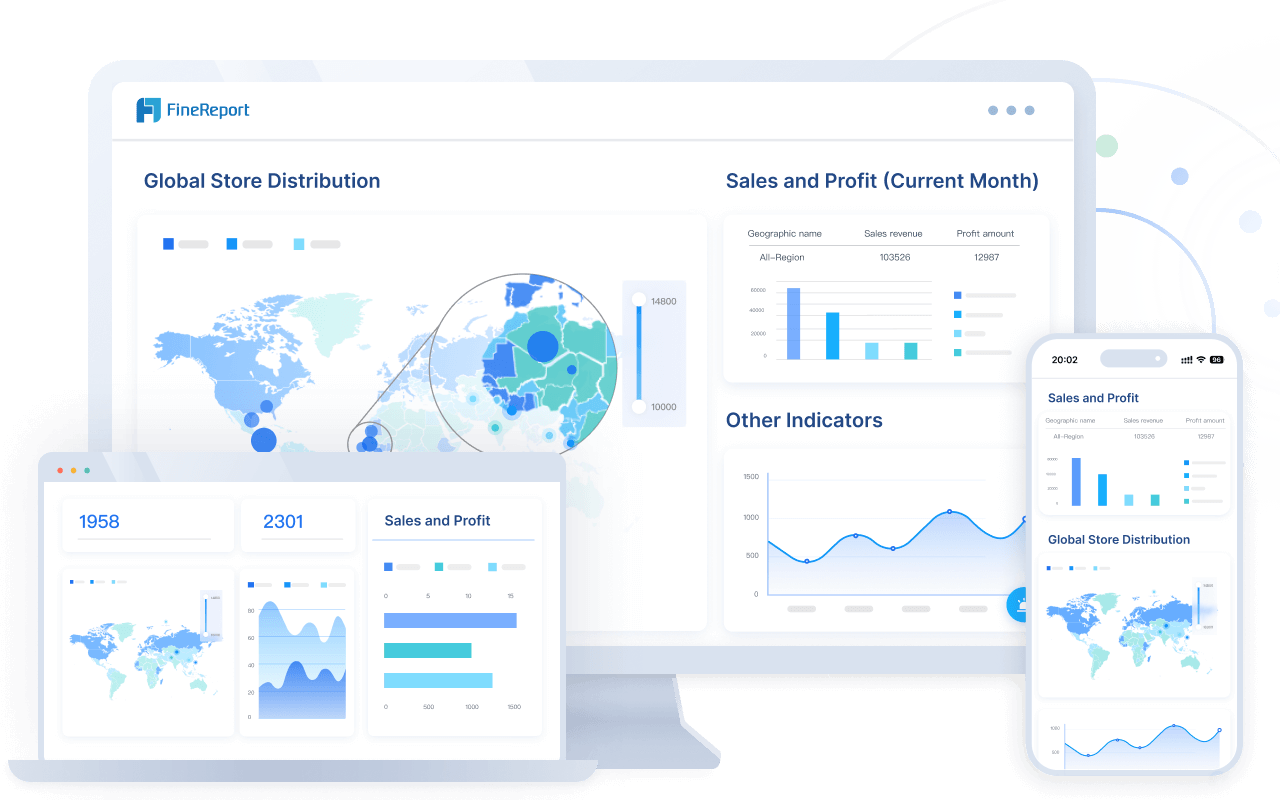

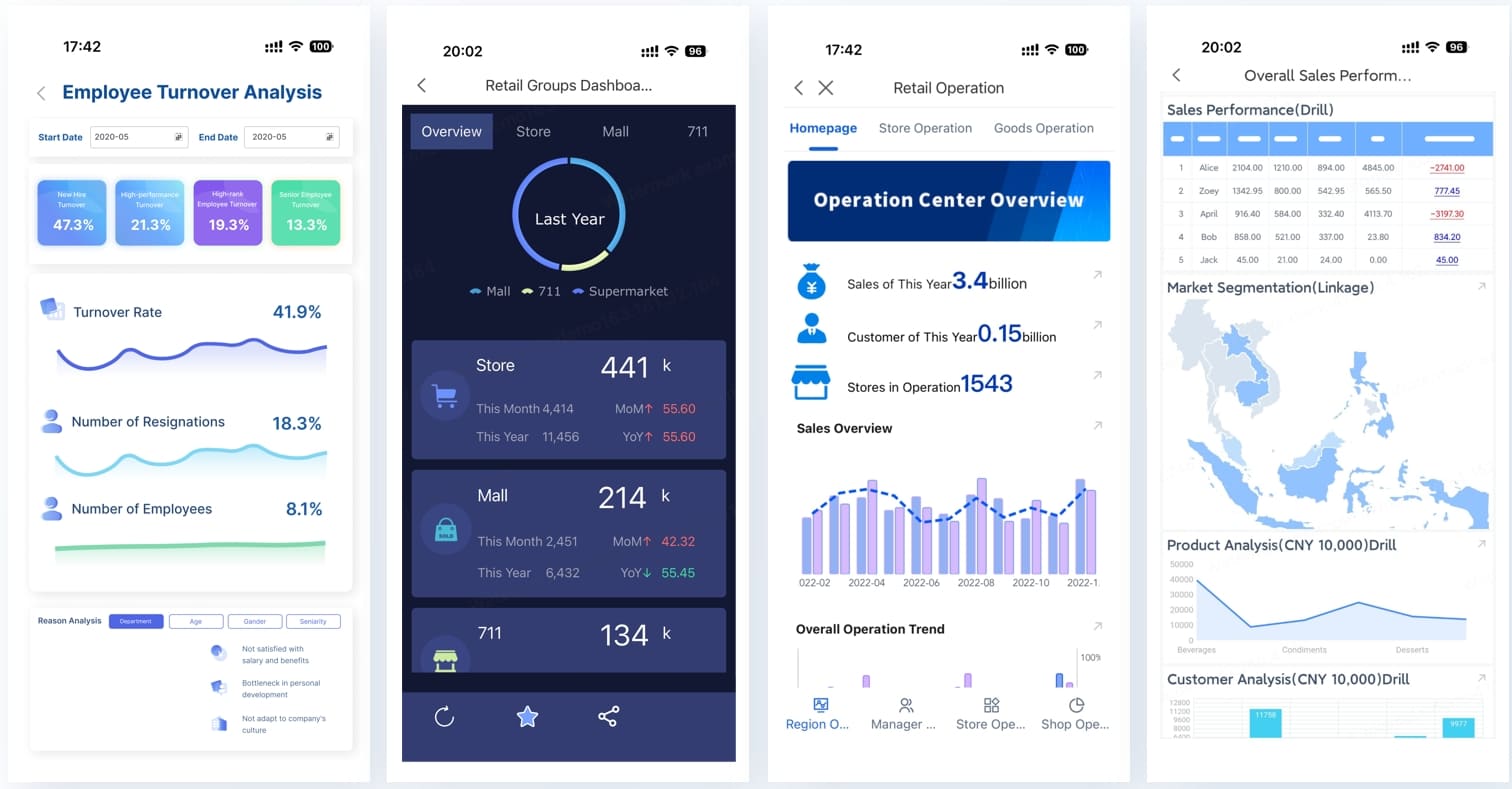

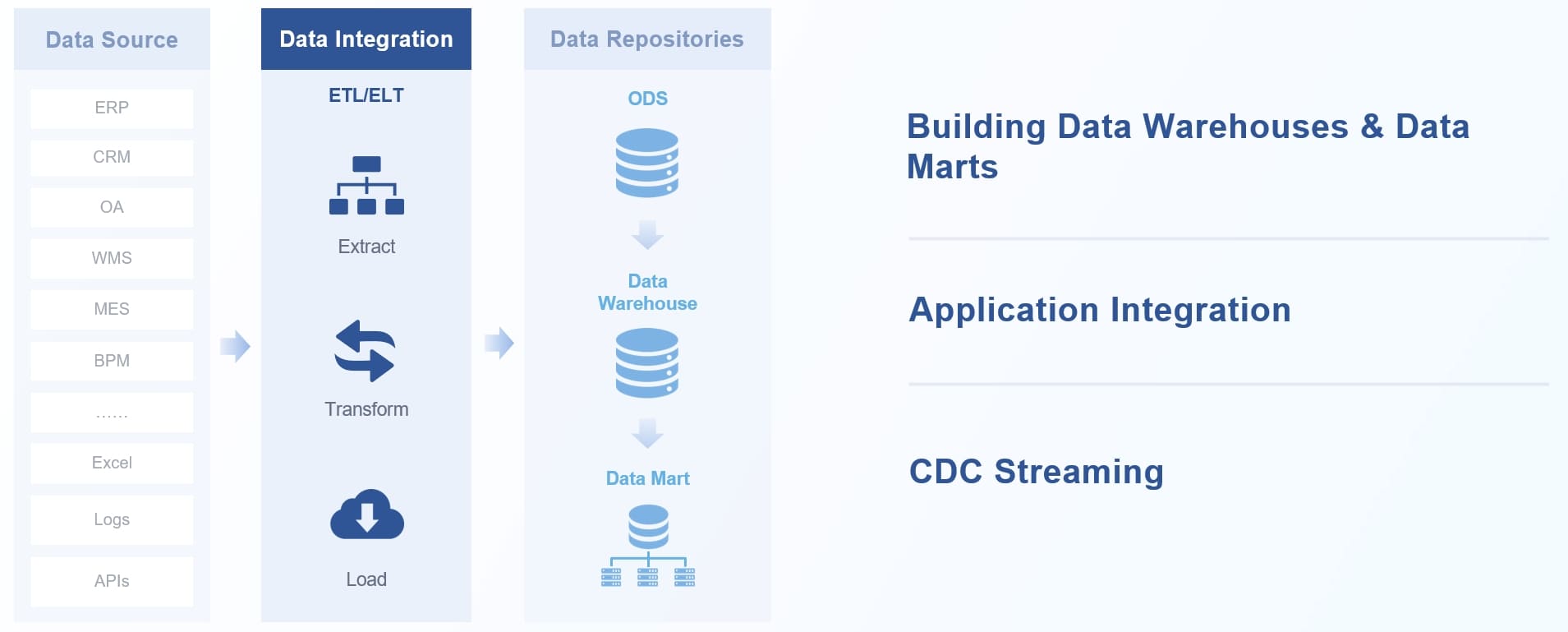

FanRuan and FineReport provide advanced solutions for real-time production monitoring in manufacturing. FineDataLink integrates data from multiple sources, breaking down silos and enabling unified data centers. FineReport connects directly to your databases and supports flexible report customization, including dashboards for desktops, mobile devices, and large screens. You can visualize live production metrics, track OEE, and monitor quality indicators in real time. The platform’s integration capabilities allow you to consolidate data from ERP, MES, and SRM systems, creating a single source of truth for your production monitoring system. Automated alerts, mobile access, and interactive dashboards ensure you stay informed and responsive, whether you are on the shop floor or offsite. With these tools, you can drive continuous improvement, maintain high production efficiency, and support agile manufacturing processes.

You will find several types of production monitoring systems in modern manufacturing. Each system focuses on different aspects of production, helping you track, analyze, and optimize your operations. Here is a quick overview:

| Type of System | Description |

|---|---|

| Overall Equipment Effectiveness (OEE) | Measures manufacturing productivity by monitoring machines to predict downtime and manage maintenance. |

| Manufacturing Execution System (MES) | Tracks and documents the transformation from raw materials to finished goods, focusing on process efficiency and quality. |

| Statistical Process Control (SPC) | Uses statistical tools to monitor production trends and detect deviations to prevent rejects. |

| Operational Historians | Collects and stores historical production data for analysis and optimization. |

Modern monitoring systems offer real-time data collection, modularity, scalability, and integration with IoT devices. You can customize these systems to fit your unique production needs and support automation, logistics, and sustainability goals.

You can elevate your production monitoring system by integrating it with FineReport and FanRuan. FineReport connects to multiple data sources, including MES, ERP, and PLCs, providing real-time dashboards and detailed reports. You gain instant visibility into production metrics, equipment status, and quality indicators. FanRuan’s FineDataLink enables seamless data integration, breaking down silos and supporting unified monitoring systems. With these tools, you can automate data collection, visualize trends, and receive real-time alerts, making your production monitoring systems more responsive and efficient.

Tip: Integration with advanced platforms like FineReport ensures your monitoring systems remain scalable and adaptable as your manufacturing operations grow.

To implement a production monitoring system effectively, follow these steps:

By following these steps, you ensure your production monitoring system delivers accurate, real-time insights and supports ongoing optimization in your manufacturing environment.

You gain instant visibility into your production environment with a production management dashboard. This tool consolidates data from multiple sources, giving you a centralized platform for monitoring key metrics. You can customize dashboards to fit the needs of different roles. Floor managers track production output, while quality control specialists focus on defect rates. Integration with ERP systems and data hubs ensures you see accurate, unified information. Real-time data visualization supports quick decisions and operational adjustments. You can set up alarms for anomalies, allowing you to respond before issues disrupt production. Secure, role-based access lets authorized personnel view dashboards on any device, maintaining data integrity.

Tip: Customization and integration capabilities allow each department to focus on the metrics that matter most, supporting cohesive operations and better strategies.

You drive continuous improvement by using comprehensive production analysis. Manual data collection slows you down and introduces errors. Automation and software platforms eliminate lag and human mistakes, giving you real-time analytics. You identify root causes faster and gain deeper insights into trends and patterns. Automated systems help you systemize improvements across your enterprise, preventing process drift. You use tools like OEE, value stream mapping, and statistical process control to reduce variation and defects. Lean tools such as error-proofing and quick changeovers improve equipment reliability and minimize downtime. You foster a culture of operational excellence by encouraging small, daily changes that add up to significant improvements.

| Tool Name | Key Features and Capabilities | Contribution to Production Analysis |

|---|---|---|

| Minitab | Statistical analysis, control charts, regression analysis | Data-driven decision-making and process improvement |

| SIMUL8 | Simulation, bottleneck identification, resource optimization | Scenario modeling for workflow optimization |

| Lucidchart | Collaborative process mapping and diagramming | Team collaboration and inefficiency identification |

| Microsoft Visio | Advanced diagramming, flowchart creation | Clarity in process visualization and workflow |

| Insight7 | Self-service platform for large data analysis | Actionable insights for operational excellence |

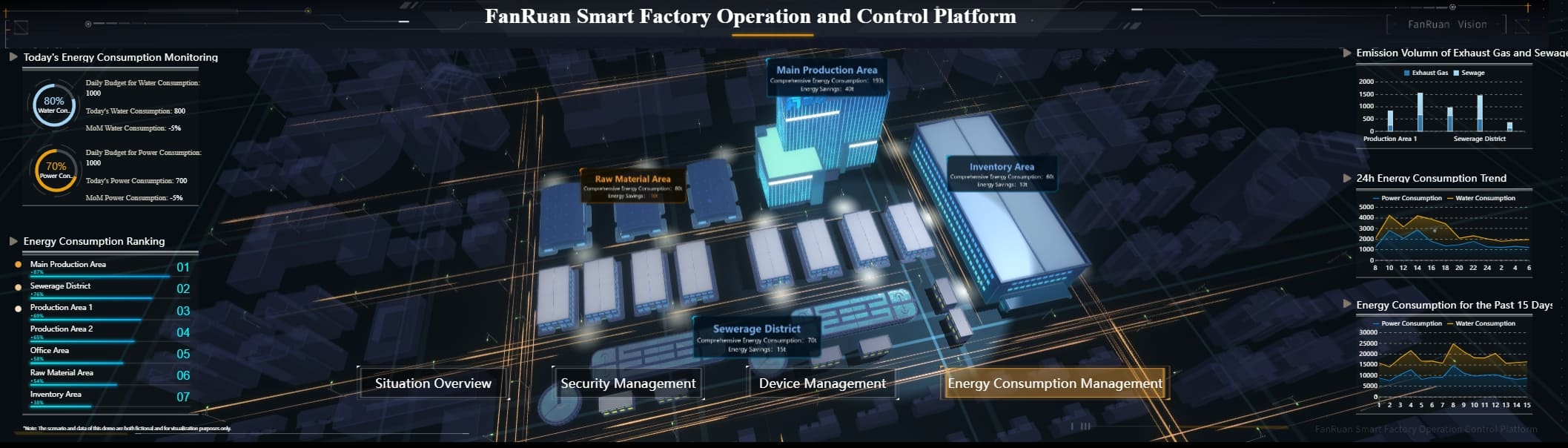

You implement a factory operation and control platform to unify your production monitoring efforts. This platform integrates data from machines, sensors, and business systems, providing a single source of truth for your production metrics. You monitor production performance, equipment status, and quality indicators in real time. The platform supports automated alerts, mobile access, and interactive dashboards, keeping you informed wherever you are. You optimize resource allocation, reduce downtime, and achieve improved product quality. You foster collaboration across departments by sharing relevant metrics and insights. With a robust control platform, you maintain agility and responsiveness, supporting ongoing production monitoring and continuous improvement.

Note: A unified control platform ensures you act on insights quickly, driving efficiency and supporting strategic goals in your manufacturing operations.

You will encounter several challenges when you implement production monitoring in your facility. Many manufacturers overestimate machine utilization rates. Monitoring systems often reveal that actual usage is lower than expected. Operators who manage multiple machines face divided attention and timing conflicts, which can increase errors. Small but frequent stoppages, such as jams or misfeeds, add up to significant productivity loss. Manual reporting captures opinions instead of facts, making it hard to set the right priorities. Bottlenecks often remain hidden without proper monitoring, which prevents targeted improvements. Housekeeping issues, like swarf management, can cause unexpected downtime. Sometimes, production output does not match the hours invested, and staffing miscalculations or skill gaps reduce efficiency.

| Issue | Description |

|---|---|

| Overestimating Utilisation | Actual machine use is often lower than believed. |

| Managing Multiple Machines per Operator | Divided attention and timing conflicts increase error risks. |

| Small but Frequent Stoppages | Minor stops accumulate to major productivity loss. |

| Reliance on Manual Reporting | Opinions replace facts, leading to misplaced priorities. |

| Bottleneck Blindness | True causes of slowdowns remain hidden. |

| Housekeeping Issues | Overlooked tasks cause unexpected downtime. |

| Output vs. Hours Misalignment | Production output does not match labor hours. |

| Staffing Miscalculations and Skill Gaps | Incorrect staffing reduces efficiency and increases downtime. |

You may also face data quality issues, integration difficulties with ERP or MES, and user adoption challenges. Address these by validating data, using standardized protocols, and providing ongoing training.

You can overcome production monitoring challenges by following proven strategies:

Tip: Involve your team in every step to boost adoption and drive quality improvement.

You can achieve significant returns by investing in production monitoring systems. Companies often see a 20% reduction in defect rates and a 25% increase in First Pass Yield when integrating AI with MES. Inventory turnover improves by 10-15%. A medium-sized manufacturer saved up to $22,646 monthly and achieved an ROI of 2276% by digitizing paper-based processes.

| Metric/Aspect | Details/Value |

|---|---|

| Monthly Savings | Up to $22,646 |

| ROI | 2276% |

| Key Cost Savings | Digitizing manual processes |

| Additional Benefits | Improved scheduling, lower maintenance costs, faster time to market |

You maximize ROI by reducing labor costs, minimizing downtime, speeding up changeovers, increasing throughput, and lowering defects. Use the formula (Gains – Costs) / Costs to measure your return. Focus on these areas to get the most from your monitoring investment.

You drive manufacturing success when you invest in production monitoring. Real-time monitoring transforms your operations by identifying bottlenecks, reducing downtime, and improving quality. Automated systems like FanRuan and FineReport help you optimize resource use and spot issues early. With these tools, you can:

Production monitoring empowers you to make smarter decisions and secure a competitive edge for the future.

Click the banner below to try FineReport for free and empower your enterprise to transform data into productivity!

What is Manufacturing Operations Management and Why It Matters

Best Manufacturing Management Software for Modern Factories

How to Create a Manufacturing Dashboard (Step-by-Step Guide)

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025