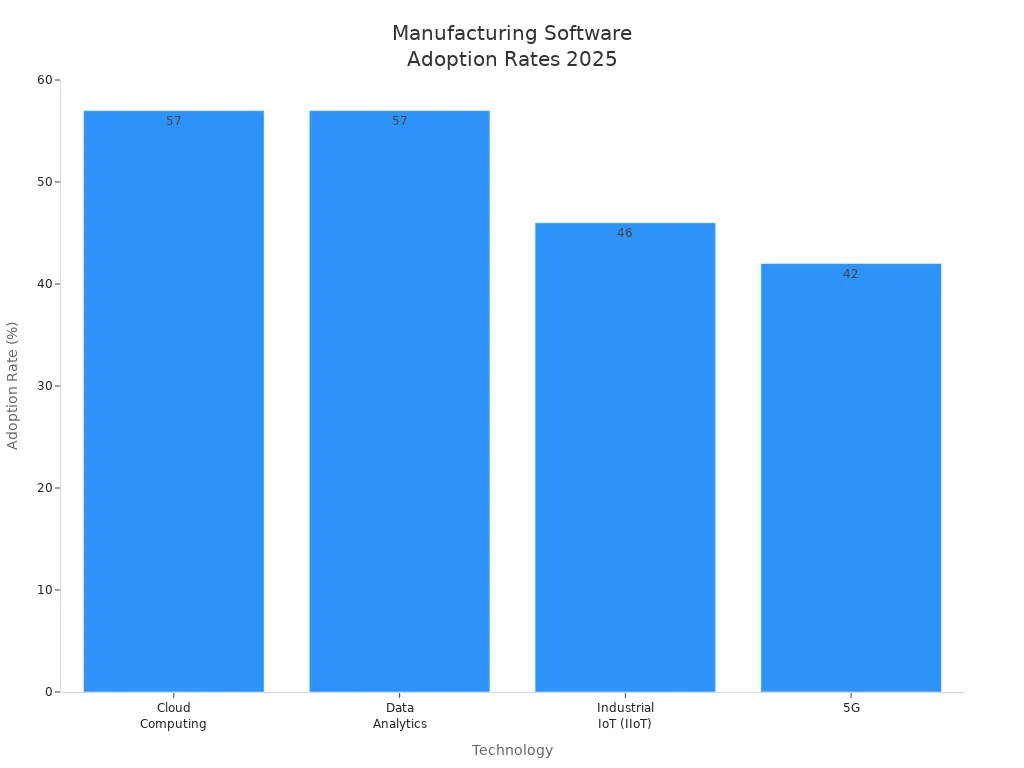

Looking for the best manufacturing software to boost your production in 2025? You’re not alone. Manufacturers everywhere want smarter tools that help them keep up with rapid changes. Digital transformation has completely changed the game. You now see factories using cloud computing, data analytics, and AI for real-time insights and faster decisions.

Check out the latest adoption rates:

| Technology | Adoption Rate (%) |

|---|---|

| Cloud Computing | 57 |

| Data Analytics | 57 |

| Industrial IoT | 46 |

| 5G | 42 |

Choosing the right erp software for the manufacturing industry means looking for innovation, seamless integration with MES, QMS, and SCM, scalability, and a great user experience. You’ll see how digital tools can make your manufacturing more efficient, cut costs, and help you stay ahead. Here are the 10 best manufacturing software platforms you can try:

You want a platform that covers all your bases. Microsoft Dynamics 365 Business Central gives you just that. This solution brings together production planning, inventory management, and shop floor control. You can connect it with Office 365 and Power BI, so reporting and analytics feel seamless. The platform adapts as your business grows, whether you run a small shop or a large plant. You get real-time data sharing and built-in security, which means your team stays connected and your information stays safe.

Website: https://www.microsoft.com/en-us/dynamics-365/products/business-central

Tip: If you already use Microsoft tools, you’ll find the integration smooth and familiar.

Key Features:

| Pros | Cons |

|---|---|

| Integration with Microsoft tools | Steep learning curve |

| Flexible deployment options | Challenges with non-Microsoft integrations |

| Broad features for various operations | Complexity of setup and implementation |

| Centralized data capabilities |

Best for: Manufacturers who want a flexible, scalable solution and already use Microsoft products.

Oracle NetSuite stands out as a cloud-based erp software that supports integration with ERP, MES, QMS, and SCM systems. You can track and monitor production operations in real time. The platform offers barcode scanner interfaces and tablet apps, making data entry quick and easy on the shop floor. You can configure it for different manufacturing environments, which helps you release work orders efficiently.

Website: https://www.oracle.com/corporate/contracts/cloud-services/netsuite/

| Feature | Description |

|---|---|

| MES Integration | Integrate your MES with NetSuite’s ERP—no need for a separate MES. |

| Manufacturing Module | Track, monitor, and collect production data. |

| Data Entry Interfaces | Use barcode scanners or tablets for fast, accurate data entry. |

| Use Case | Description |

|---|---|

| Advanced planning and scheduling | Plan and use shop floor resources to cut operating costs. |

| Discrete/assembly manufacturing | Use configurable work order logic and enhanced data collection for assembly. |

| Batch/process manufacturing | Get FIFO material issuance and batch lot tracking for quality control. |

| Mobile capability | Scan barcodes and use tablets for real-time MES reporting. |

| Extended setup criteria | Configure for different manufacturing environments to improve work order release. |

Best for: Companies needing strong integration and mobile capabilities for complex manufacturing.

Epicor ERP gives you global scalability and flexibility. You can run it in the cloud, on-premises, or as a hybrid. The platform comes with built-in features for complex manufacturing, so you don’t need a lot of third-party add-ons. Epicor uses Microsoft Azure for its cloud infrastructure, which means you get automatic updates and strong security.

Website: https://www.epicor.com/en-us/

| Feature | Epicor ERP | Other ERP Systems |

|---|---|---|

| Cloud Infrastructure | Microsoft Azure-backed | Varies by vendor |

| Scalability | Global scalability, auto updates | Limited scalability |

| Industry-Specific Design | Built-in for complex manufacturing | Often needs third-party add-ons |

| Implementation Time | Shorter, out-of-the-box | Longer, more customization |

| Last-Mile Capabilities | 90% out of the box | Needs more development |

| Flexibility | Cloud, Hybrid, On-Premises | Limited options |

Note: Some users struggle with training and system configuration. Make sure your team gets proper onboarding.

Best for: Large manufacturers with complex needs who want a flexible, scalable solution.

SAP Business One focuses on small and medium-sized manufacturers. You can improve cost estimates, shorten your quotation cycle, and get products to market faster. The platform helps you minimize cost overruns and improve your value-at-risk rate. You can collaborate across departments and use flexible manufacturing strategies.

Website: https://www.sap.com/products/erp/business-one.html

Key Benefits:

Best for: Small and mid-sized manufacturers who want to streamline operations and boost margins.

MRPeasy is a favorite among small manufacturers who want a simple, effective mrp solution. You can manage production, procurement, inventory, and sales in one place. The platform integrates with accounting systems like QuickBooks and Xero, so you can sync invoices and inventory movements automatically. You get real-time cash flow visibility and one-click invoice sending.

Website: https://www.mrpeasy.com/

Why You’ll Like It:

Best for: Small manufacturers who need a straightforward mrp and accounting integration.

Odoo Manufacturing brings smart factory features to your fingertips. You can automate quality checks at every stage of production. The analytics tools turn raw data into actionable insights, so you can generate custom reports easily. Odoo’s Work Centers centralize operations management and optimize resource allocation. Predictive maintenance helps you spot equipment issues before they become problems. The IoT Box connects your machines for real-time data collection, and PLM features keep engineering changes under control.

Website: https://www.odoo.com/app/manufacturing

Key Features:

Best for: Manufacturers looking for a flexible, all-in-one platform with smart factory and IoT capabilities.

Cetec ERP gives you real-time views of inventory, supply constraints, and open orders. You can test what-if scenarios to see how changes in labor or materials affect your production timeline. The live planning dashboards replace static spreadsheets, so you always see current operations. Cetec’s built-in business intelligence lets you create custom reports and visualize data for quick insights.

Website: https://cetecerp.com/

| Feature | Description |

|---|---|

| Real-time views | See inventory, supply, and orders instantly. |

| What-if scenarios | Test changes in labor/materials on timelines. |

| Live dashboards | Move from static spreadsheets to dynamic dashboards. |

Best for: Manufacturers who want real-time analytics and easy-to-build custom reports.

ERPNext is an open-source mrp and manufacturing erp software that puts you in control. You can automate material requests and stock orders, which prevents stockouts. The platform standardizes tasks to cut mistakes and boost predictability. Automatic checks ensure consistent product standards, and demand forecasting helps you avoid overproduction. You get real-time tracking and instant alerts, so your team can adapt quickly.

Website: https://frappe.io/erpnext

| Feature | Advantage |

|---|---|

| Smoother Workflows | Structured BOM saves time and improves planning. |

| Task Automation | Automatic material requests and stock orders prevent stockouts. |

| Reducing Human Intervention | Standardized tasks cut mistakes and boost predictability. |

| Minimizing Errors | Automatic checks ensure consistent product standards. |

| Preventing Overproduction | Demand forecasting aligns output with customer needs, reducing waste. |

Best for: Manufacturers who want open-source flexibility and deep automation.

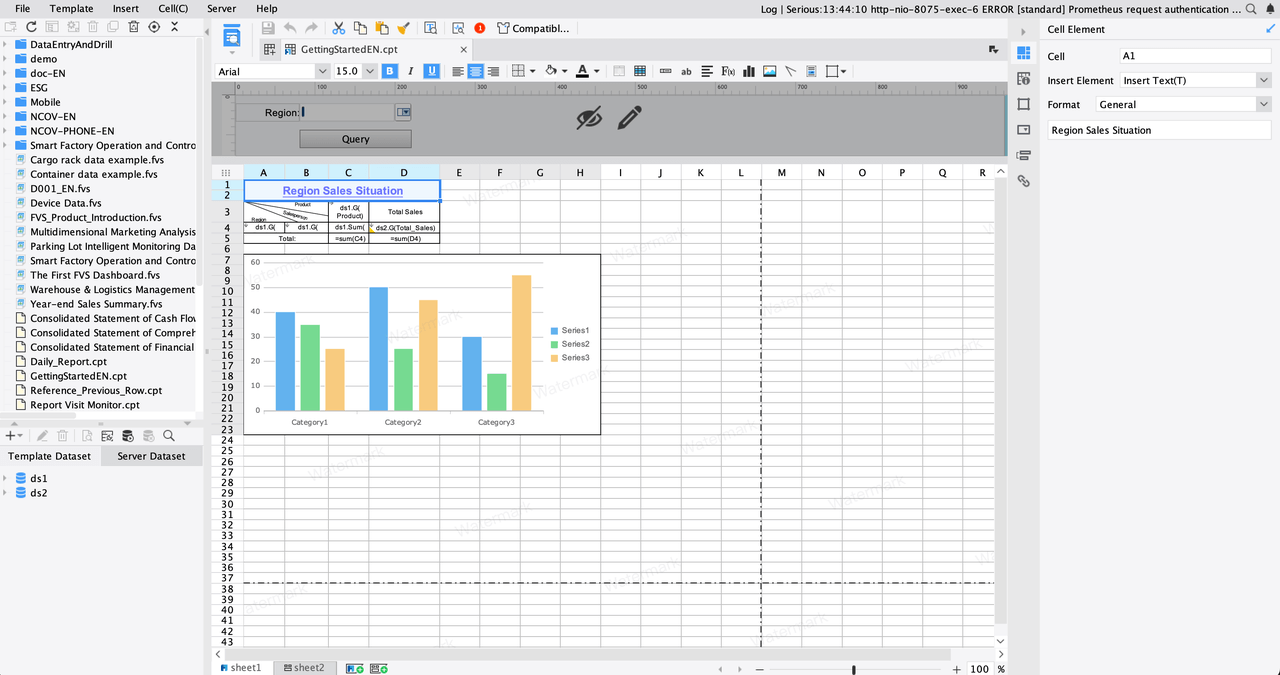

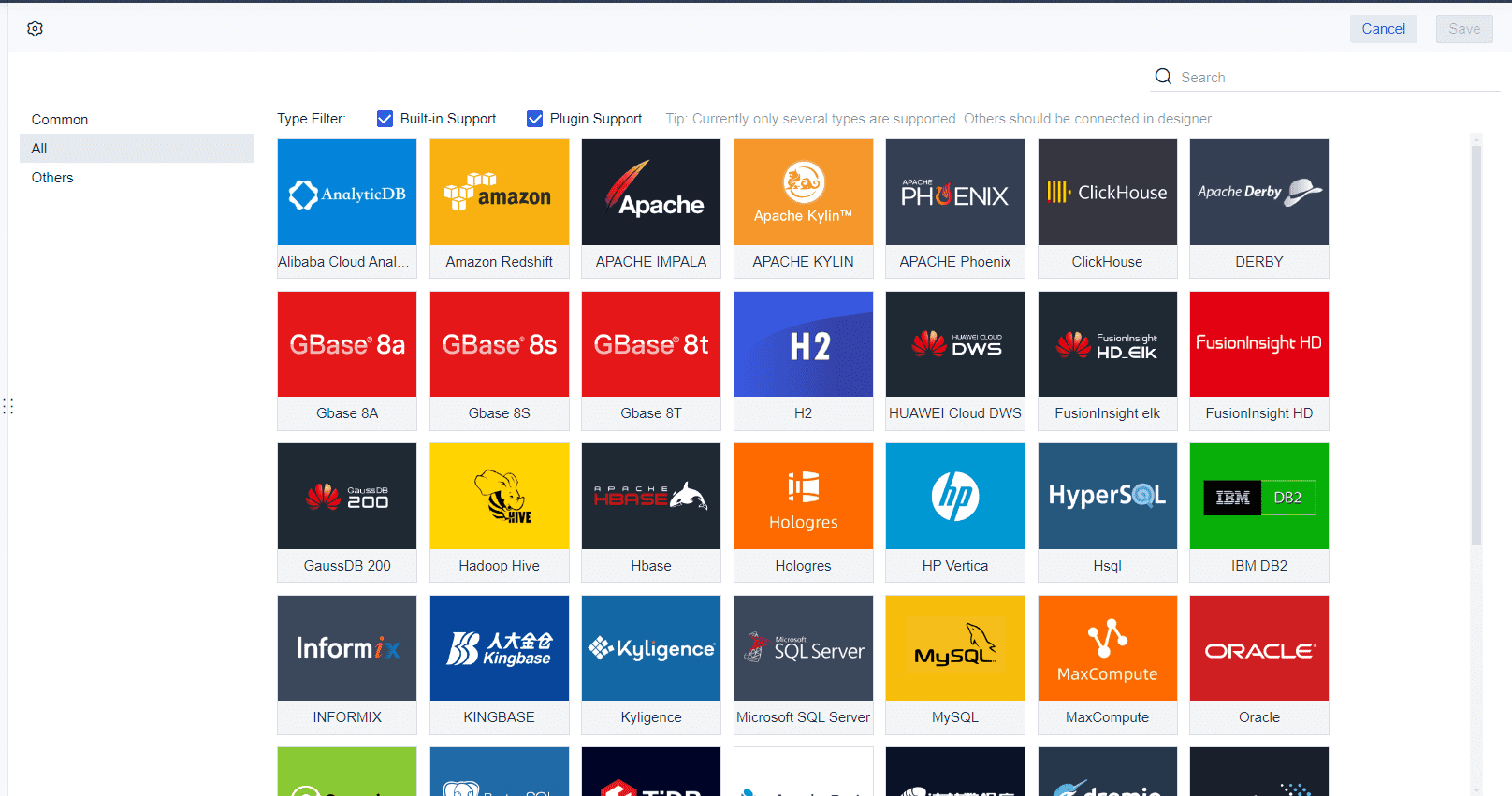

FineReport stands out as one of the top manufacturing erp software solutions for data integration, reporting, and smart factory transformation. You can connect to almost any data source, including mainstream databases, ERP, MES, and more. The drag-and-drop report designer makes it easy to create highly formatted reports and interactive dashboards. You get real-time data visualization with a wide range of chart styles, which helps you spot trends and make decisions faster.

Website: https://www.fanruan.com/en/finereport

Pro Tip: FineReport’s secure environment lets you manage reports and control access with ease.

| Feature | Description |

|---|---|

| Data Integration | Connect to various data sources for comprehensive analysis and reporting. |

| Report Design | Create pixel-perfect reports and dashboards quickly. |

| Real-time Visualization | Use dynamic charts to enhance data interpretation. |

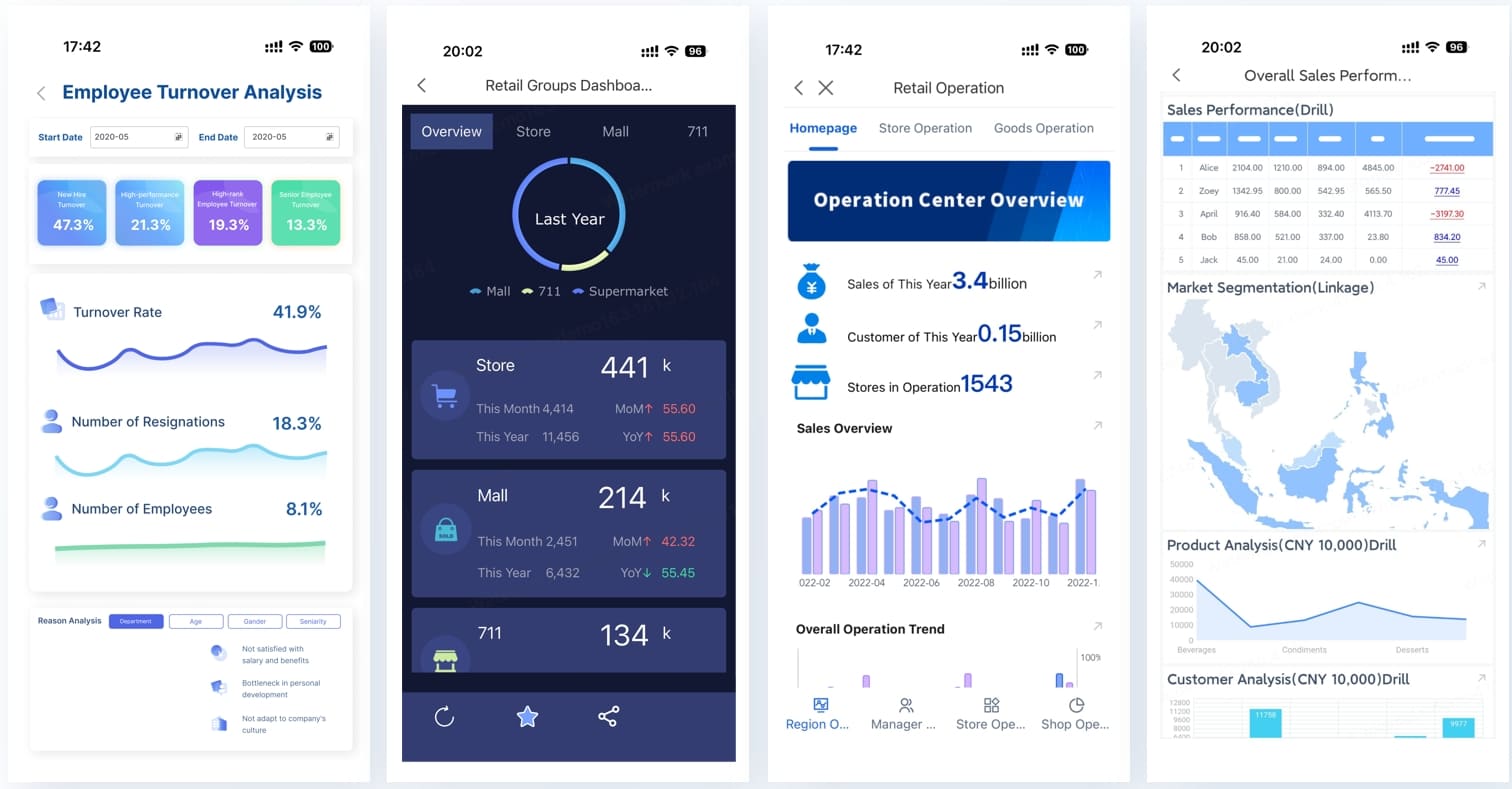

You can deploy FineReport independently or integrate it with your existing systems. The platform supports mobile access, so you can view reports and dashboards anywhere. If you want to build a smart factory, FineReport gives you the tools to unify your data, monitor production in real time, and drive continuous improvement.

Best for: Manufacturers who need advanced reporting, seamless data integration, and smart factory capabilities.

Infor CloudSuite Industrial is built for large-scale manufacturing. You get specialized functionality for engineer-to-order, make-to-order, and make-to-stock production. The platform offers advanced project management, so you can control resources, timelines, and costs for long-term projects. Multi-site coordination keeps you connected across global networks. Integrated financial management supports complex costing and global consolidation.

Website: https://www.infor.com/resources/infor-cloudsuite-industrial-brochure

| Key Differentiators | Description |

|---|---|

| Specialized Functionality | Tailored for complex manufacturing processes. |

| Advanced Project Management | Controls resources, timelines, and costs for long-term projects. |

| Multi-Site Coordination | Maintains visibility across global manufacturing networks. |

| Integrated Financial Management | Supports global financial consolidation and complex costing models. |

Best for: Large manufacturers with complex, multi-site operations and advanced project needs.

If you’re searching for the best manufacturing erp software, these top manufacturing erp solutions cover every need—from mrp and production erp software to cloud-based erp software for the manufacturing industry. Whether you want the best erp system for manufacturing or the best erp software for manufacturers, you’ll find a platform here that fits your business.

You want your manufacturing business to stay ahead. The best manufacturing erp software brings you the latest tech. These platforms use AI for predictive maintenance and quality control. IoT connects your machines for real-time monitoring. Digital twins let you test production changes before you make them on the floor. Cloud computing gives you flexibility and lower costs. Edge computing helps you process data right where the action happens. Here’s a quick look at the top technologies you’ll find in today’s manufacturing erp software:

| Technology | Description |

|---|---|

| AI | Predicts maintenance needs, forecasts demand, and automates quality checks. |

| IoT | Connects sensors for real-time monitoring and better efficiency. |

| Digital Twins | Lets you test production changes virtually before making them real. |

| Cloud Computing | Offers scalability and reduces maintenance costs. |

| Edge Computing | Processes data near production lines for faster decisions. |

You get smarter, faster, and more reliable production with these tools.

Your manufacturing needs change as you grow. The best manufacturing erp adapts with you. You can customize workflows to fit your unique processes. No-code solutions let you make changes without needing a developer. Cloud-based manufacturing erp software gives you real-time visibility and supports your growth. Seamless integration means you can connect with your existing systems. Rapid deployment gets you up and running fast. Here’s what sets these platforms apart:

You want software that feels easy to use. The best manufacturing erp software solutions focus on user-friendly dashboards and clear navigation. You get helpful support, training, and resources. This means your team spends less time learning and more time making things happen. Mobile access lets you check reports and dashboards anywhere, so you never miss a beat.

Every manufacturing business is different. The best erp system for manufacturing offers features for your industry, whether you run a small mrp shop or a global production line. You get specialized modules for mrp, supply chain, quality control, and more. These platforms help you manage everything from inventory to compliance. You can trust your manufacturing erp software to handle the details, so you can focus on growth.

Tip: Look for production erp software that matches your industry’s needs. You’ll save time and avoid headaches.

If you want the best manufacturing erp software for your business, choose a platform that brings innovation, flexibility, and industry know-how. You’ll see the difference in your daily operations.

You want your manufacturing business to run smoother and faster. The best manufacturing erp software uses automation and AI to make that happen. These tools handle repetitive tasks, spot problems early, and help you focus on what matters most. Check out some of the top AI features you’ll find:

| AI Feature | Application Description |

|---|---|

| Processing and reconciling invoices | Automates the handling of invoices, reducing manual effort and errors. |

| Managing inventory reorders | Automatically adjusts inventory levels based on usage patterns, ensuring optimal stock levels. |

| Providing early warning of business issues | Alerts users to potential problems before they escalate, allowing for proactive management. |

| Answering common procedural questions | Uses AI to provide quick responses to frequently asked questions, improving user efficiency. |

| Coordinating maintenance schedules | Automates the scheduling of maintenance tasks, ensuring equipment is serviced timely. |

| Identifying patterns in business data | Analyzes data to uncover trends and insights that can inform decision-making. |

You’ll see Oracle AI Apps, machine learning, and smart automation in action. These features help you get more done with less effort.

You need to know what’s happening on your shop floor right now. Manufacturing erp software gives you real-time visibility into every part of your operation. You can track mrp, production management, and inventory management without delay. This means you can make smart choices fast.

Implementing an ERP system enhances collaboration and communication within the organization. With a single source of truth, all stakeholders can access the same data in real time, improving coordination and reducing errors.

You get data-driven decision-making that keeps you ahead of the competition.

Managing your supply chain and inventory can get tricky. The best manufacturing erp software brings everything together. You can handle inventory and warehouse management, supply chain management, and mrp in one place. This helps you avoid stockouts and overproduction. You can also use inventory management software to keep track of every part and product.

You want your products to meet high standards. Manufacturing erp software includes quality management tools that help you monitor production, catch defects, and stay compliant with industry rules. Automated checks and real-time production monitoring make sure you deliver top-quality goods every time.

Every manufacturing business is unique. The best erp system for manufacturing lets you customize workflows and connect with other tools. You get seamless integration with cloud-based solutions, on-premises erp, and cloud erp software. This flexibility means you can grow and change without missing a beat. Production erp software adapts to your needs, whether you focus on mrp or full-scale production management.

When you look at manufacturing erp software, you see a mix of strengths and weaknesses. Some platforms shine with seamless integration and real-time visibility. Others may need extra customization for advanced mrp or production management. Here’s a quick table to help you compare:

| ERP System | Common Strengths | Common Weaknesses |

|---|---|---|

| NetSuite | Cloud-native, integrated business tools, auto updates | Basic manufacturing features compared to specialists |

| Acumatica | User-friendly, flexible licensing, good for growth | Limited advanced manufacturing for complex needs |

| QAD | Automotive expertise, strong supply chain management | Discrete manufacturing could be deeper |

| Kinetic | Modern interface, quick setup, fits standard processes | Struggles with complex discrete manufacturing |

| Dynamics 365 | Microsoft integration, familiar experience, unified processes | May need more customization for manufacturing |

| General | Great CAD integration, strong design-to-manufacturing | Needs more business management beyond execution |

You want to pick a solution that matches your needs. If you focus on mrp, supply chain management, or quality management, check if the platform covers those areas well.

Not every manufacturing erp software fits every business. You need to match the platform to your company’s size and goals.

| ERP System | Best Suited For | Notable Pros | Notable Cons |

|---|---|---|---|

| Acumatica Cloud ERP | Small to large manufacturers | Real-time data access, open architecture | Higher implementation costs, complexity |

| SAP Business One | Growing companies, complex inventory | Real-time synchronization, customer insights | Long implementation time, higher costs |

| Sage Intacct | Small/medium discrete manufacturers | Cloud-native, real-time insights | Escalating costs, limited features |

Manufacturers using these platforms have seen big improvements. Some report a 208% ROI with payback in just four months. That’s a huge win for your bottom line.

You want the best manufacturing erp for your industry. Automotive, electronics, and food production all have unique needs. Some platforms offer specialized modules for manufacturing resource planning, inventory management, and data-driven decision-making. Others focus on mrp and quality management for discrete or process manufacturing.

If you want manufacturing software that grows with you, look for manufacturing erp software solutions that match your industry and business size. You’ll get better results and smoother operations.

When you start looking for new manufacturing erp software, you want to make sure it checks all the right boxes. The right features help you run your manufacturing business smoothly and keep you ahead of the competition.

You need to know what matters most before you choose a platform. Here’s a quick checklist to guide you:

If you want to get the most out of your manufacturing erp software, start with these essentials.

Security should never be an afterthought. You handle sensitive data every day in manufacturing. The best manufacturing erp software protects your information and helps you stay compliant with laws and standards. Here’s what you should look for:

Modern platforms use continuous security monitoring, intrusion detection, and automated vulnerability scanning. You also get strict access controls and secure update mechanisms. These features keep your mrp and production management data safe.

Even the best manufacturing erp software won’t help if your team can’t use it. You want a platform that offers clear training and ongoing support. Look for:

A good vendor will help you get started and stay productive. With the right support, you can unlock the full power of your mrp and manufacturing software.

Tip: Don’t skip training. Well-trained teams make fewer mistakes and get more value from their software.

You want your manufacturing business to run smoother and faster. When you use manufacturing erp software solutions, you see real changes in how your team works. You can track every step of your mrp process, spot problems early, and fix them before they slow you down. With real-time data, you make better decisions and keep your production lines moving.

Here’s a quick look at what you can expect:

| Benefit | Description |

|---|---|

| Improved Inventory Management | ERP systems help monitor inventory levels, ensuring production meets market demand without excess. |

| Enhanced Collaboration | Centralized data access improves decision-making and reduces errors, leading to higher productivity. |

| Simplified Workflow | Streamlining processes helps identify inefficiencies, allowing for quicker resolutions and better output. |

| Lowering Costs | Cloud-based ERP solutions reduce operational costs compared to traditional systems. |

| Supporting a Mobile Workforce | Remote access to data enables employees to work efficiently from various locations, minimizing downtime. |

You get more done in less time. Your team spends less time searching for information and more time making products.

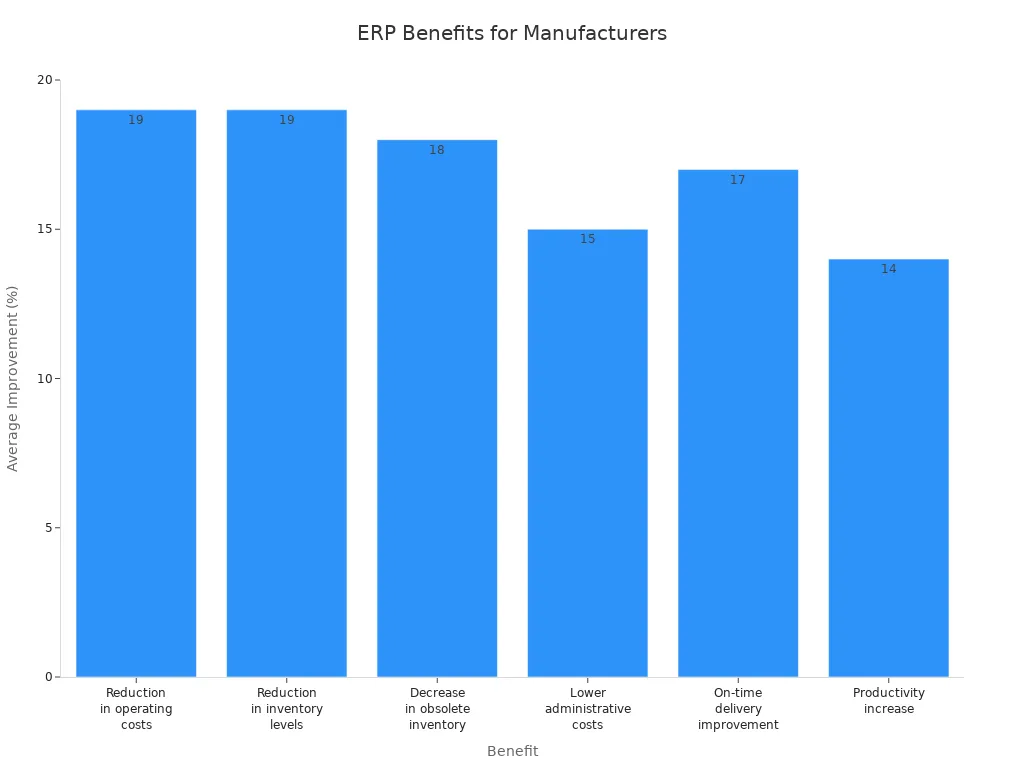

You want to save money and see a real return on your investment. Manufacturing erp software solutions help you cut costs in many ways. You can reduce waste, lower inventory, and avoid expensive mistakes in your mrp process. Many manufacturers report big improvements after switching to these systems.

Check out these average results:

You can see how these numbers add up to real savings and better production efficiency.

You need your team to work together, not in silos. Manufacturing erp software solutions bring everyone onto the same page. With one source of truth, your mrp, inventory, and production teams all see the same data. This means fewer mistakes and faster problem-solving.

You can share updates instantly. Managers and workers can check dashboards and reports from anywhere. Better communication leads to higher operational efficiency and a happier team. When everyone works together, your manufacturing business grows stronger.

You want your manufacturing business to run smoother and smarter. Start by looking at what you need most. Every company has different goals for mrp, production efficiency, and operational efficiency. Make a list of your must-have features. Do you need better inventory tracking? Are you looking for real-time mrp updates? Maybe you want to connect your shop floor with your office systems.

Here’s a quick table to help you focus on what matters:

| Criteria | Description |

|---|---|

| Functionality | The software must meet your specific business needs. |

| Integration | It should connect with your current systems for seamless operations. |

| Total Cost of Ownership | Look at all costs, not just the price tag. |

| Vendor Expertise | Choose a vendor who knows manufacturing and your industry. |

| Support | Make sure you get help after you go live. |

You can also use this checklist:

You want a partner you can trust. Research each vendor’s experience in manufacturing. Ask for case studies and customer stories from businesses like yours. Look for vendors who offer strong training and support. Good support means you solve problems faster and keep your mrp running smoothly.

Here’s what to check:

| Key Point | Description |

|---|---|

| Vendor Experience | Ask for examples from your industry and similar company sizes. |

| Support & Training | Look for hands-on help during setup and after you start using the system. |

| Vendor Credibility | Check reviews, market presence, and financial stability. |

Tip: A reliable vendor helps you get the most out of your erp software for the manufacturing industry.

Don’t just look at the sticker price. You need to count every cost. That means licenses, setup, training, updates, and support. Some systems cost more upfront but save you money later. Others seem cheap but add up over time. Make sure your choice fits your budget and helps you boost mrp and operational efficiency.

Think about where you want your manufacturing business to go. Will your mrp needs change as you grow? Pick a system that can scale with you. Look for flexible features and easy upgrades. You want software that supports new products, more users, and bigger goals. Planning ahead keeps your production efficiency high and your business ready for anything.

Adopting new software in manufacturing can feel overwhelming. You might worry about how your team will react or if your systems will work together. Let’s break down the biggest hurdles and see how you can tackle them.

Change can make people nervous. When you bring in new mrp software, some employees may resist. You need to show your team how the new system will help them. Talk about the benefits, like faster production and easier tracking. Prepare your staff before the switch. Give them time to ask questions. Set clear goals for your project team. Good communication helps everyone stay on the same page. If you keep expectations realistic, you avoid surprises.

You probably use different tools for manufacturing and mrp. Connecting new software with your old systems can be tricky. Data migration is a big deal. You want to keep your information safe and accurate. Work closely with your vendor. Make sure they understand your needs. Test the integration before you go live. If you spot problems early, you fix them faster. Open communication with your vendor helps you get support when you need it.

Getting everyone to use the new mrp software is key. Some people may not feel ready. You can help by offering training and support. Create onboarding plans that make learning easy. Appoint ‘super-users’ who can answer questions and help others. Use digital adoption platforms to guide your team through new features. If you keep productivity high during the transition, your manufacturing business stays strong.

Here are some common challenges you might face:

- Misaligned expectations between teams and vendors

- Data integrity issues during migration

- Lack of preparedness among project teams and employees

- Inadequate vendor support

- Weak training tools

- Declining productivity

You can overcome these challenges with strong planning, clear communication, and ongoing support. Your manufacturing business will run smoother, and your mrp process will get better results.

You want your manufacturing business to run smoothly. FineReport helps you connect all your data sources, from ERP to MES, so you can see everything in one place. You can pull in data from your mrp system, production lines, and even quality checks. This means you get real-time updates on every part of your process. You don’t have to wait for reports or dig through spreadsheets. FineReport lets you spot issues fast and fix them before they slow down your manufacturing. You can trust your numbers because the data comes straight from your mrp and other systems.

Tip: Real-time reporting helps you make quick decisions and keeps your team on track.

You need clear insights to keep your manufacturing business ahead. FineReport gives you visual dashboards that show your key metrics at a glance. You can track mrp, inventory, and production status with easy-to-read charts and graphs. These dashboards help you see trends and spot problems early. You can customize your view to focus on what matters most for your manufacturing goals. With FineReport, you don’t just get data—you get answers that help you make smart choices every day.

Let’s look at a real example. Yieh Phui Enterprise, a leader in steel coil manufacturing, wanted to improve their mrp and reporting. Their old system made it hard to get clear data. After switching to FineReport, they connected their ERP, MES, and other tools. Now, they create reports and dashboards in minutes, not days. Managers see real-time updates on production and mrp. They can react fast to any changes on the shop floor. Yieh Phui’s team spends less time on manual work and more time improving manufacturing results. Their story shows how FineReport can transform your mrp and help you build a smarter factory.

When you choose the right manufacturing software, you set your business up for smarter production. You get better control over mrp, faster decisions, and real-time insights. The best manufacturing tools help you solve problems before they slow you down. Always match your software to your manufacturing needs and future goals. Real-world examples, like FineReport, show how mrp and manufacturing can work together for success. Try a demo or trial to see how mrp software can transform your manufacturing process.

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025