Sustainable manufacturing means creating products through processes that support the economy and protect the environment. The EPA defines it as making goods in ways that conserve energy, use natural resources wisely, and reduce harmful impacts.

In 2025, you face new rules and rising expectations.

- The Eco-design for Sustainable Products Regulation and EU Deforestation Regulation demand better product design and transparent sourcing.

- Firms now set more ESG targets, invest in renewable energy, and focus on waste reduction to stay competitive.

By adopting sustainable manufacturing, you can improve efficiency, meet regulations, and show leadership in protecting the planet.

Sustainable Manufacturing Explained

Key principles

You need to understand what sets sustainable manufacturing apart from traditional approaches. Sustainable manufacturing means you design, produce, and manage products with a focus on long-term impact. You do not just look at profit or speed. You consider how your choices affect the environment, your employees, and the community.

Here are the key principles that define sustainable manufacturing:

- Holistic approach: You integrate environmental, social, and economic factors into every step of your process.

- Energy and waste: You optimize how you use resources, reduce waste, and adopt energy-efficient technologies.

- Eco-friendly considerations: You choose sustainable materials, assess the full life cycle of your products, and source responsibly.

- Social responsibility: You support fair labor practices and invest in the wellbeing of your employees and local communities.

You can see the differences between sustainable manufacturing and traditional manufacturing in the table below:

| Principle | Sustainable Manufacturing | Traditional Manufacturing |

|---|---|---|

| Resource Efficiency | Focuses on optimizing materials, energy, and water usage. | Often prioritizes cost and speed. |

| Waste Reduction | Emphasizes recycling and closed-loop systems. | Waste is often not minimized. |

| Renewable Energy | Shifts to renewable sources like solar and wind. | Relies on fossil fuels. |

| Social Responsibility | Prioritizes worker safety and inclusivity. | Less focus on social impacts. |

Sustainable manufacturing creates a closed-loop system. You repurpose waste as raw material, use renewable energy, and design products for reuse or remanufacturing. This approach reduces emissions and pollution. You save costs over time by using fewer resources. You also meet government standards more easily.

Tip: When you adopt sustainable manufacturing, you help your business become more resilient and future-ready.

2025 relevance

In 2025, sustainable manufacturing is more important than ever. You see companies shifting their priorities toward energy and water efficiency. Manufacturers now use advanced digital technologies to boost efficiency and sustainability. Global supply chains are changing because of new tariffs and demands for transparency. You must innovate in how you source materials and refine your processes.

Sustainable manufacturing is no longer a niche idea. It is now a central pillar for long-term competitiveness. The global market for sustainable manufacturing is projected to grow from USD 233.56 billion in 2025 to USD 367.18 billion by 2029. This growth comes from increased awareness of environmental issues and stronger regulations. New technologies in renewable energy and recycling make manufacturing more efficient.

You need to pay attention to these trends:

- Companies focus on energy and water efficiency as a strategic goal.

- Digital tools and automation improve sustainability and transparency.

- Supply chains adapt to new tariffs and stricter reporting requirements.

- Manufacturers see sustainable manufacturing as essential for staying competitive.

If you want your business to thrive, you must embrace sustainable manufacturing. You will reduce your ecological footprint, promote resource efficiency, and ensure ethical working conditions. You will also contribute to your community and meet the expectations of customers and regulators.

Why Sustainable Manufacturing Matters

Environmental impact

You play a key role in shaping the environment through your manufacturing choices. Industrial production often leads to negative effects on the planet. It contributes to climate change, harms ecosystems, and affects biodiversity and human health. The manufacturing industry uses 54% of global energy resources, which results in high fossil fuel consumption, especially in energy-intensive sectors. This heavy use of energy increases carbon emissions and accelerates climate change.

Many Americans recognize the urgency of this issue. About 70% believe human activity contributes to climate change, and 56% think we should act now to address it. By adopting sustainable manufacturing, you can help reduce your company’s carbon footprint. Switching to renewable energy sources and improving energy efficiency are crucial steps. These actions lower emissions and help protect the environment for future generations.

You can also make a difference by tracking and managing carbon emissions. For example, some manufacturers use advanced analytics to monitor carbon intensity in real time. This approach leads to ongoing carbon reduction and better energy management. Setting clear metrics for emissions performance allows you to measure progress and improve your sustainability efforts.

Economic and social value

Sustainable manufacturing offers more than environmental benefits. You gain real economic advantages by optimizing energy use, reducing waste, and improving resource efficiency. The table below shows some of the main financial benefits:

| Financial Benefit | Description |

|---|---|

| Lower Resource and Production Costs | Save money by using less energy and materials. |

| Lower Regulatory Compliance Costs | Stay ahead of regulations and avoid penalties. |

| Improved Sales and Brand Recognition | Attract customers who value sustainability. |

| Greater Access to Financing and Capital | Qualify for green bonds and investment opportunities. |

| Easier Employee Hiring and Retention | Attract and keep employees who care about sustainability. |

You also support your community and workforce. Sustainable manufacturing creates safer workplaces and supports local economies. It promotes job opportunities and improves well-being for employees and residents. By choosing this approach, you help build a healthier, more resilient society.

Sustainable Manufacturing Benefits For Manufacturers

Efficiency and cost savings

You can achieve significant efficiency gains and cost savings by adopting sustainable manufacturing practices. When you invest in energy-efficient machinery, you reduce your energy consumption and lower your utility bills. Using renewable energy sources, such as solar or wind, can cut your energy costs and may even provide financial incentives like tax credits. Waste reduction and recycling help you use resources more efficiently, which lowers disposal costs and improves your profit margins. Sustainable manufacturing methods also reduce your carbon footprint and operational costs, making your business more attractive to customers and investors.

Here is a table that shows how different strategies lead to real benefits:

| Strategy | Benefits |

|---|---|

| Energy-efficient machinery | Reduces manufacturing costs through optimized energy consumption and long-term savings. |

| Renewable energy sources | Cuts energy costs significantly and provides financial advantages like tax credits. |

| Waste reduction and recycling | Lowers disposal costs and improves profit margins through efficient resource utilization. |

| Sustainable manufacturing methods | Reduces carbon footprint and operational costs while enhancing market appeal. |

Many companies have already seen measurable results. For example, Coca-Cola reduced water usage and improved recycling, which saved resources and enhanced its corporate image. Adidas focused on sustainable products and supply chain initiatives, attracting environmentally conscious consumers. Ford invested in electric vehicles and sustainable practices, which improved its competitiveness and profitability. These examples show that sustainable manufacturing is not just good for the planet—it is also good for your bottom line.

Compliance and reputation

You face increasing pressure to meet new compliance requirements in 2025. Regulations like the EU's Corporate Sustainability Reporting Directive (CSRD) require you to disclose your environmental, social, and governance (ESG) impacts. California's SB261 expands sustainability disclosures, making it necessary to provide transparent information about your practices. Extended Producer Responsibility (EPR) programs hold you accountable for the entire life cycle of your products, including recycling and disposal.

| Compliance Requirement | Description |

|---|---|

| EU's Corporate Sustainability Reporting Directive (CSRD) | Mandates comprehensive disclosures on ESG factors, requiring companies to assess their impacts on people and the environment. |

| California's SB261 | Expands sustainability disclosures, requiring manufacturers to provide transparent information about their environmental practices. |

| Extended Producer Responsibility (EPR) Programs | Holds manufacturers accountable for the environmental impacts of their products throughout their life cycles, including recycling and disposal. |

You may also need to align with global standards such as the Global Reporting Initiative (GRI) and the Task Force on Climate-related Financial Disclosures (TCFD). Meeting these requirements helps you avoid penalties and builds trust with regulators and stakeholders.

Sustainable manufacturing also improves your reputation. Customers and partners look for companies that show leadership in sustainability. When you emphasize responsible practices, you attract environmentally conscious customers and build loyalty. Customer participation in sustainable programs encourages you to adopt even more responsible practices. This approach influences purchasing preferences and supports strategies like remanufacturing. By positioning your brand as a leader in corporate responsibility, you gain a competitive edge and strengthen your relationships with stakeholders.

Sustainable Manufacturing Implementation Strategies

To achieve success in sustainable manufacturing, you need clear strategies that address resource use, data-driven decision-making, and supply chain improvements. Each area plays a vital role in helping your organization meet environmental goals and regulatory requirements.

Resource and energy management

Resource and energy management forms the foundation of sustainable manufacturing. You can adopt several practical strategies to reduce waste, lower costs, and improve efficiency:

- Install renewable energy systems, such as solar panels, to generate clean electricity on-site. For example, a mid-sized furniture manufacturer in California installed a 2-megawatt solar array on its factory roof. This system now powers 80% of the facility’s energy needs during peak production hours, reducing reliance on the grid and lowering operating costs.

- Implement waste heat recovery systems. A large brewery in Colorado captures thermal energy from its brewing process and uses it to preheat water for the next cycle. This approach reduced natural gas consumption by 20%.

- Use advanced energy management systems. A leading aerospace manufacturer adopted an IIoT-enabled energy management system, which led to a 10% reduction in energy costs and a 15% improvement in overall equipment effectiveness.

You can see the impact of these strategies in the table below:

| Energy Efficiency Improvement | Source |

|---|---|

| 165% | Austrian energy efficiency policy program |

These examples show that investing in resource and energy management not only supports sustainable manufacturing but also delivers measurable financial and operational benefits.

Tip: Start with a detailed audit of your facility’s energy and resource use. Identify areas where you can implement renewable energy, recover waste heat, or automate energy management.

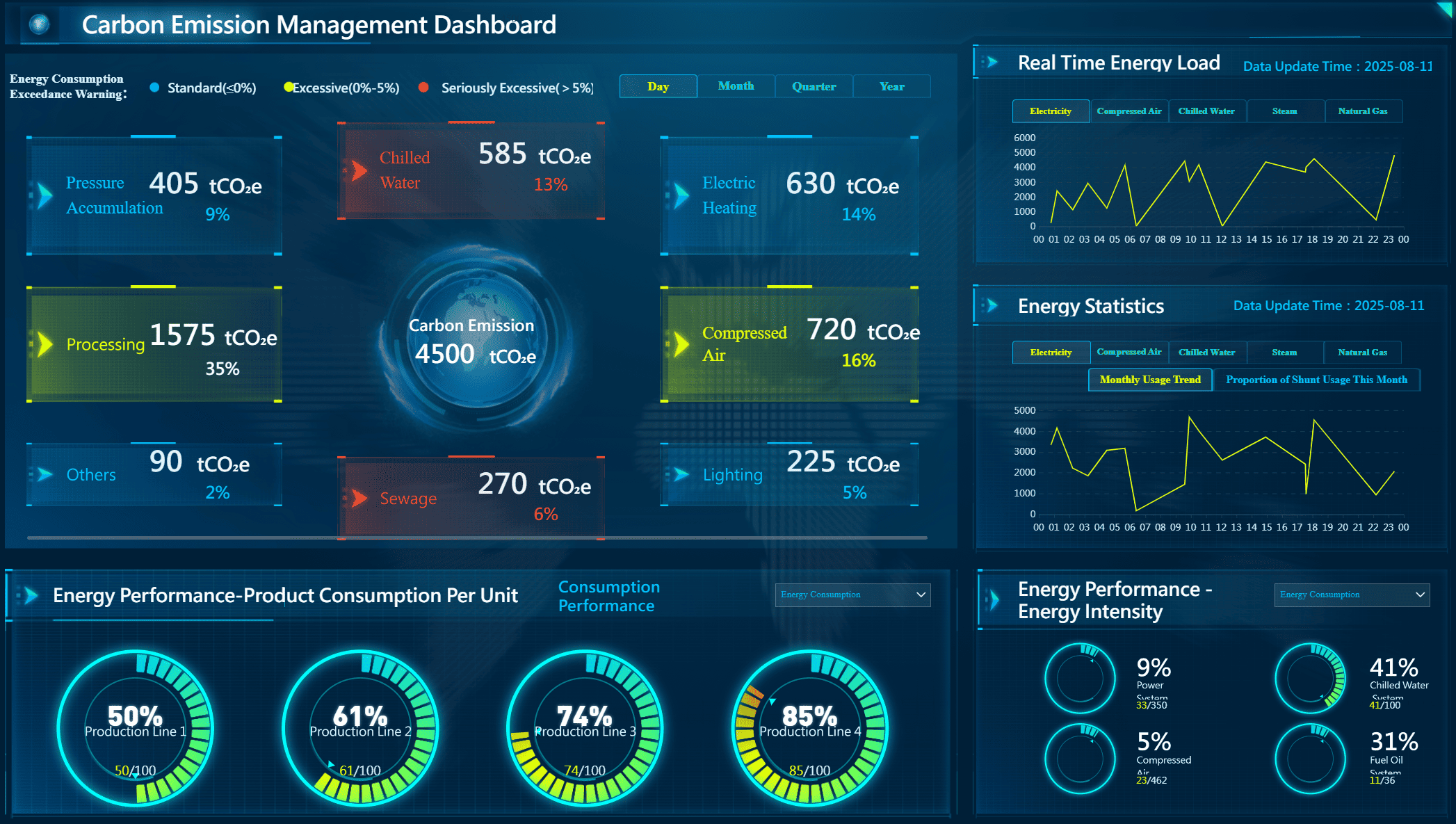

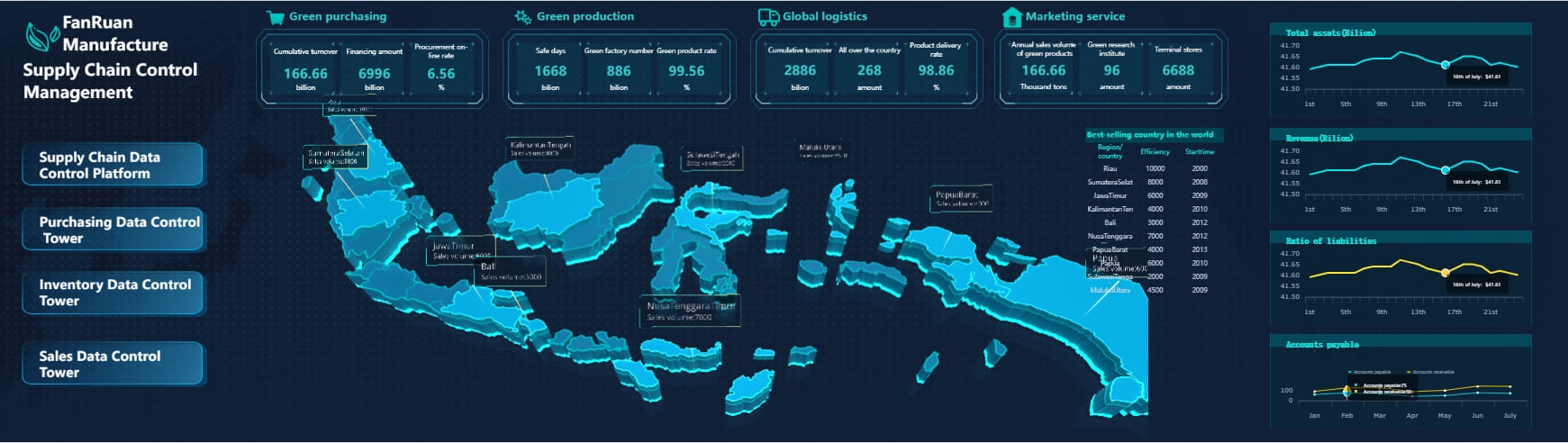

Data-driven decisions with FineReport

Data-driven decision-making is essential for sustainable manufacturing. You need accurate, real-time information to monitor performance, track progress, and ensure compliance. FineReport empowers you to collect, analyze, and visualize data from multiple sources, supporting smarter decisions at every level.

FineReport enables you to:

- Integrate data from various systems, including ERP, CRM, and production equipment, into a single platform.

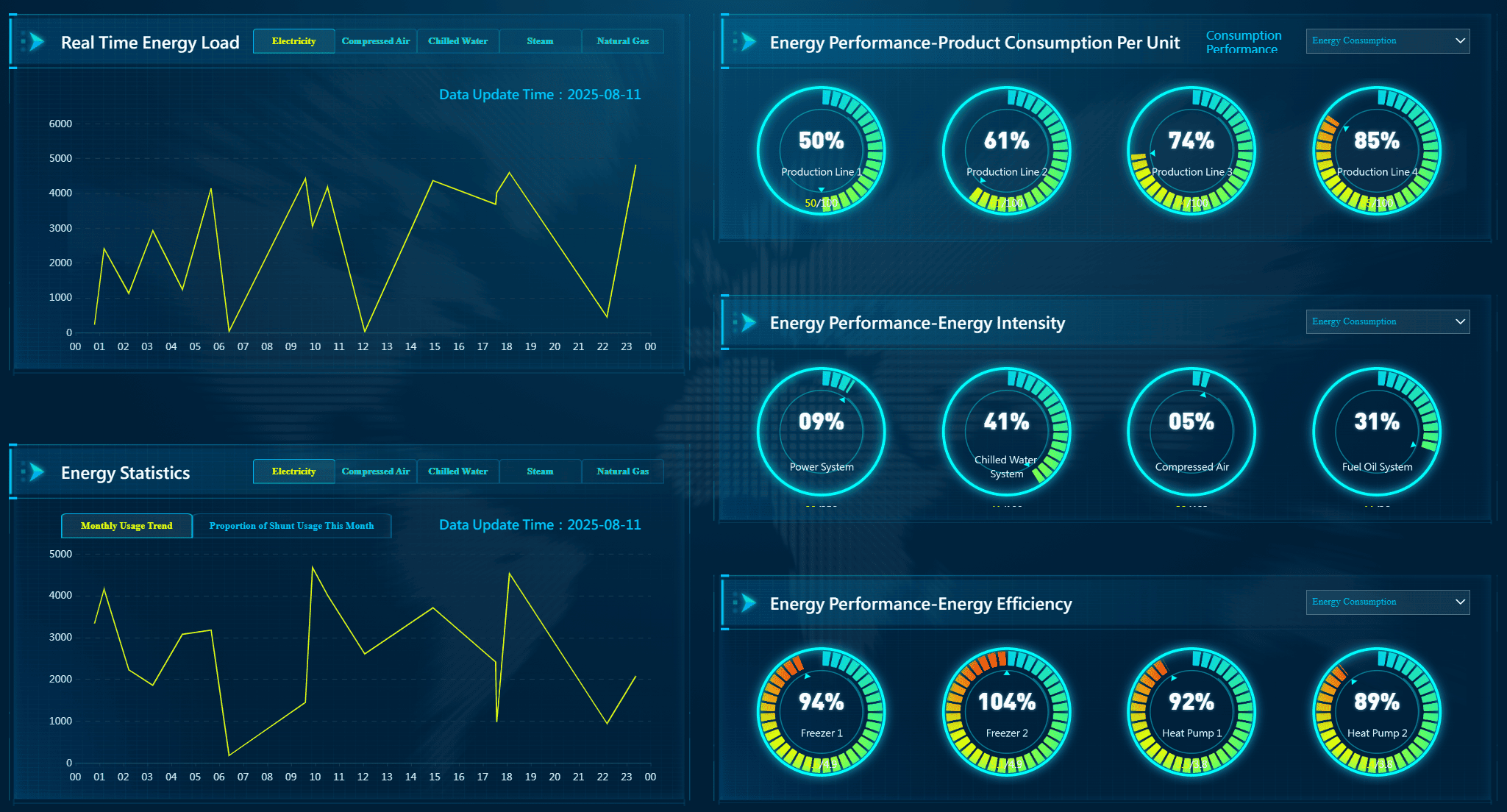

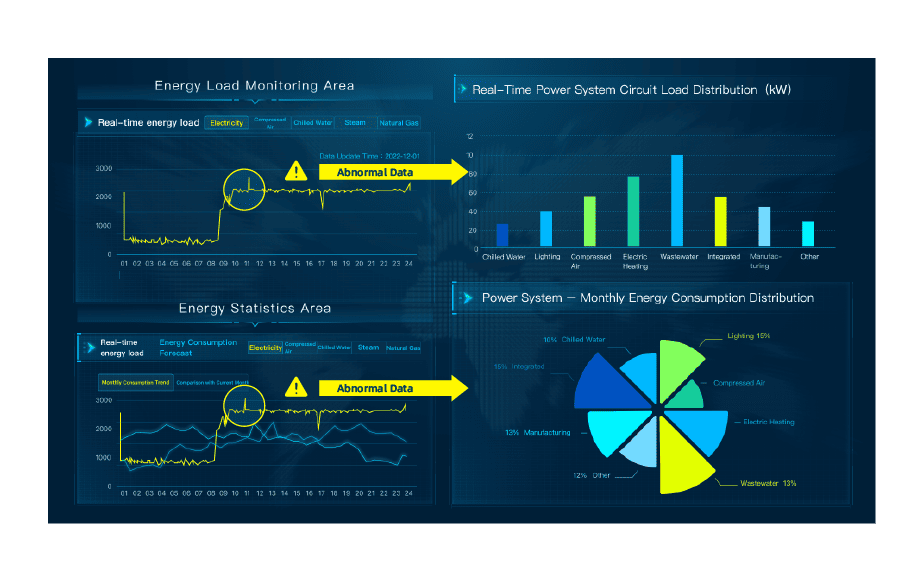

- Create dynamic dashboards and reports that display key performance indicators (KPIs) for energy use, emissions, and production efficiency.

- Automate compliance reporting, reducing manual work and minimizing the risk of errors.

- Monitor real-time metrics on mobile devices, allowing you to respond quickly to issues on the shop floor or in the field.

The table below highlights how FineReport compares to other reporting tools:

| Feature | FineReport | InetSoft |

|---|---|---|

| Reporting Type | Static reports | Dynamic dashboards |

| Data Integration | Limited, manual data combination | Robust, automated data mashup |

| Real-time Tracking | No real-time updates | Interactive dashboards with real-time metrics |

| Financial Reporting | Standard expenditure reports | Integrated financial and project outcome dashboards |

| Compliance Reporting | Manual data compilation | Automated compliance risk flags |

With FineReport, you can enhance real-time tracking of safety standards and environmental restoration phases. You also improve financial oversight by linking expenditures to project outcomes, which builds trust with stakeholders. Automated compliance reporting helps you identify risks early and maintain proactive safety measures.

FanRuan’s ESG solution further strengthens your sustainable manufacturing efforts. It provides real-time energy monitoring, carbon emission tracking, and anomaly detection. You can visualize operations in 3D, receive mobile alerts, and ensure compliance with global standards like ISO 50001 and ISO 14064-1. These tools help you optimize processes, reduce costs, and achieve your sustainability goals.

Note: Data-driven platforms like FineReport and FanRuan’s ESG solution give you the visibility and control needed to drive continuous improvement in sustainable manufacturing.

Supply chain improvements

Supply chain improvements are critical for sustainable manufacturing. You must look beyond your own operations and consider the entire lifecycle of your products, from raw materials to final disposal.

Key strategies include:

- Keeping inventory-to-sales ratios lean. This approach minimizes excess stock, reduces waste, and conserves resources.

- Evaluating supplier performance based on timeliness, quality, and cost. This fosters a more eco-friendly supply chain.

- Collaborating with suppliers to set shared sustainability targets and reduce carbon output. Standardizing emissions reporting and launching joint initiatives can help you achieve these goals.

The table below summarizes the most important supply chain improvements:

| Improvement Type | Description |

|---|---|

| Inventory Management | Keep inventory-to-sales ratio lean to minimize excess stock, reducing waste and resource use. |

| Supplier Performance | Evaluate suppliers on timeliness, quality, and cost to foster a more eco-friendly supply chain. |

| Collaboration with Suppliers | Work directly with suppliers to set shared sustainability targets and reduce carbon output. |

Sustainable supply chain management integrates environmental, social, and financial considerations into sourcing, production, and distribution. This approach reduces greenhouse gas emissions, improves working conditions, and promotes eco-friendly practices throughout the supply chain.

Sustainable supply chain management reduces emissions, enhances employee well-being, and encourages responsible practices at every stage.

By focusing on resource and energy management, leveraging data-driven tools like FineReport, and improving your supply chain, you can build a strong foundation for sustainable manufacturing. These strategies help you meet regulatory requirements, reduce costs, and position your business as a leader in sustainability.

Overcoming Challenges in Sustainable Manufacturing

Common barriers

You may encounter several obstacles when you transition to sustainable manufacturing. These barriers can slow progress and make it difficult to achieve your goals. The most common challenges include:

- Uncertainties in the markets.

- Switching from fossil fuels to renewable energy sources.

- Transport barriers.

- Supply chain complexities.

- Technological barriers.

You also face high initial investment costs for green technology and infrastructure. Many manufacturing plants have outdated systems that require upgrades. Complex supply chains add another layer of difficulty. You may struggle with a lack of standardized metrics for measuring sustainability. Balancing sustainability with profitability often requires careful planning.

| Barrier Type | Description |

|---|---|

| Internal | Low top management commitment, lack of leadership and technical expertise, lack of sustainable manufacturing resources and infrastructure, lack of awareness, training, education, and rewards systems for employees, technological risk, lack of updated information and difficulty in the evaluation of system performance throughout the life cycle. |

| External | Existing institutional and legal environment, financial constraints. |

You need to recognize these barriers early. This awareness helps you plan effective strategies for sustainable manufacturing.

Practical solutions

You can overcome these challenges by taking practical steps. Start with a comprehensive resource audit to identify and reduce waste. Use digital tools, such as resource management software, to improve efficiency. Strategic partnerships can help you share resources and develop innovative solutions.

- Conduct a resource audit to pinpoint areas for improvement.

- Leverage technology to track energy use and emissions.

- Develop partnerships with expert organizations for carbon footprint measurement and reduction.

- Use transparent reporting to showcase your environmental impact.

Easy-to-use tools for calculating and tracking carbon emissions make it simpler to monitor progress. Expert partners can guide you in reducing your carbon footprint. Transparent reporting builds trust with stakeholders.

Successful companies show that these solutions work. Patagonia implemented renewable energy and fair labor practices, which reduced its carbon footprint and earned sustainability awards. Toyota adopted lean manufacturing and waste reduction, leading to higher efficiency and lower emissions. Interface launched "Mission Zero," achieving carbon neutrality and reducing greenhouse gas emissions by 97%.

You can follow these examples to make sustainable manufacturing a reality in your organization. Focus on practical steps and continuous improvement.

Real-world Examples of Sustainable Manufacturing

Danfoss and FineReport

You can see the impact of digital transformation on sustainable manufacturing by looking at Danfoss. Danfoss, a global leader in energy efficiency, used FineReport to connect data from its machining workshop. The company faced challenges with data silos, high maintenance costs, and manual processes. By adopting FineReport, Danfoss enabled real-time monitoring, paperless operations, and streamlined workflows.

The results speak for themselves. Danfoss achieved significant reductions in energy consumption and improved operational efficiency. The table below shows the measurable outcomes:

| Outcome Description | Percentage Reduction |

|---|---|

| Equipment energy consumption reduction | 33% |

| Potential savings on standby power consumption | up to 77% |

You can use FineReport to visualize key performance indicators, track energy use, and automate compliance reporting. Danfoss’s experience shows that digital tools help you reduce emissions, save costs, and meet sustainability goals.

Industry best practices

You can follow industry best practices to strengthen your sustainable manufacturing efforts. Leading companies focus on these strategies:

| Best Practice | Description |

|---|---|

| Energy Efficiency | Use energy-efficient technologies and renewable energy to minimize consumption. |

| Waste Reduction | Apply lean manufacturing and circular economy principles to reduce waste. |

| Eco-friendly Materials | Choose recycled and bio-based materials to lower environmental impact. |

| Product Lifecycle Sustainability | Consider sustainability at every stage of the product lifecycle. |

| Integration of Advanced Technologies | Use AI and automation to optimize processes and reduce resource use. |

Many companies now scale transformative solutions instead of isolated projects. You see a shift toward circular business models that align profit with environmental impact. More organizations integrate sustainability into their core strategies.

You also benefit from ESG integration and data-driven management. About 80% of global institutional investors consider ESG factors when making investment decisions. Companies with strong ESG initiatives attract eco-conscious consumers and form valuable partnerships. Decision-support frameworks, such as those using advanced analytics, help you rank ESG performance and make better choices.

By learning from these examples and best practices, you can drive real progress in sustainable manufacturing.

You face urgent challenges and new opportunities in 2025. By adopting sustainable manufacturing, you help your business stay competitive and protect the environment. Data and technology, including solutions like FineReport, give you the tools to track progress and meet your goals. Start now by exploring best practices and using digital tools to drive real change.

Continue Reading About Sustainable Manufacturing

FAQ

The Author

Lewis

Senior Data Analyst at FanRuan

Related Articles

9 Best Supply Chain Tools for Smarter Management in 2026

Find the best supply chain tools for 2025 to boost efficiency, gain real-time insights, and achieve smarter management for your business.

Lewis

Dec 18, 2025

Top 10 Supply Chain Tracking Software for 2026

Compare the top supply chain tracking software for 2026 to boost visibility, automate workflows, and leverage AI analytics for smarter decisions.

Lewis

Dec 18, 2025

Top 10 Supply Chain Management Software for Small Businesses

See the top 10 supply chain management software comparison for small businesses in 2026. Compare features, pricing, and scalability to find your best fit.

Lewis

Dec 18, 2025