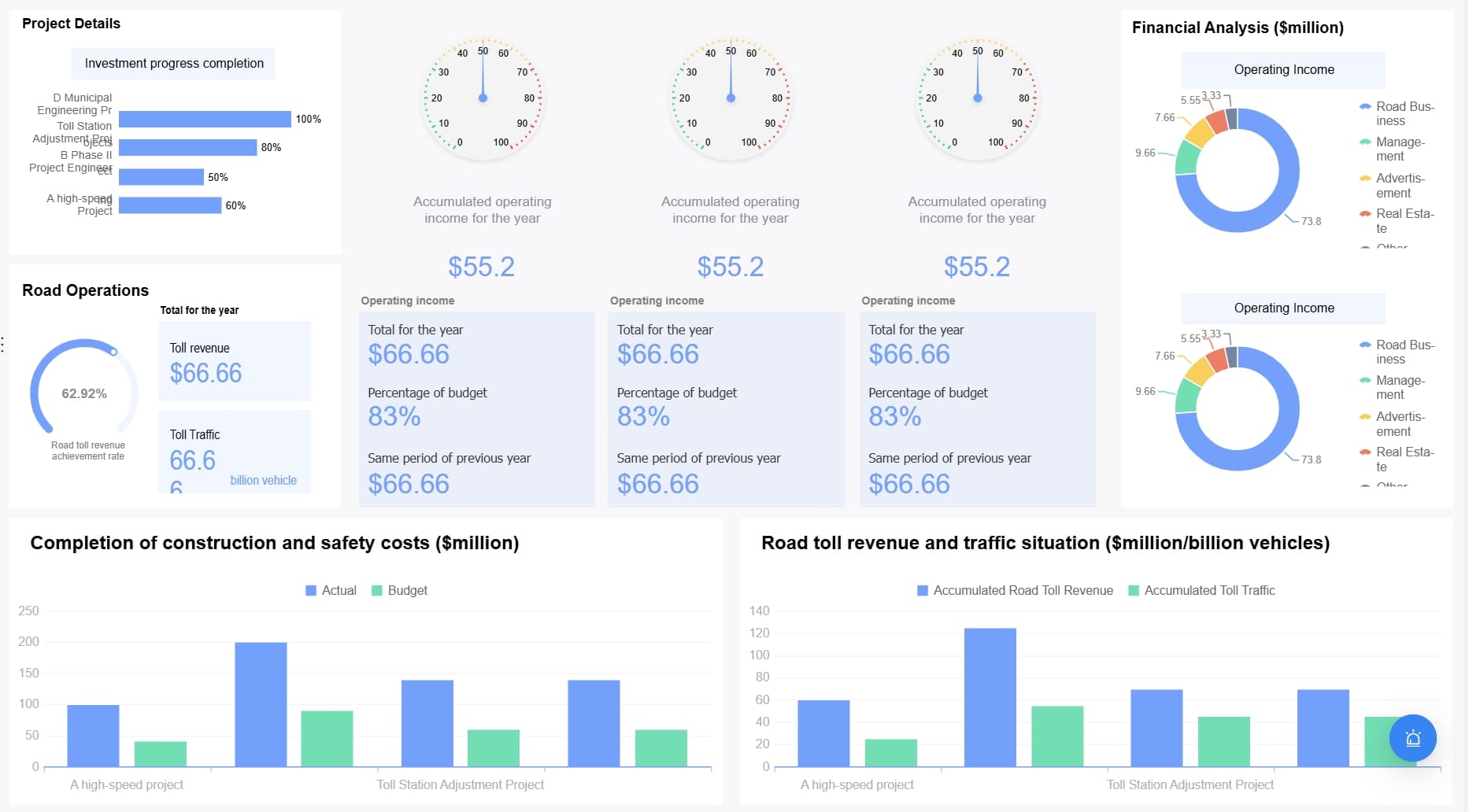

Manufacturers face urgent challenges, including labor shortages, rising costs, and complex supply chains. Smart strategies that boost manufacturing efficiency deliver measurable results. For example, Unilever increased Overall Equipment Effectiveness from 51% to 66% in one year, saving over €250,000. Companies that boost factory productivity can realize up to a 50% improvement in productivity. The table below shows recent gains achieved by global factories that focus on boosting efficiency and maximizing factory productivity.

| Metric/Aspect | Improvement/Result | Context/Details |

|---|---|---|

| Productivity boost | 26.4% increase within 90 days | Across 1,500 factories using frontline empowerment |

| Factory productivity (OEE) | Increased by 12 points (47% to 59%) | Measured across participating factories |

| Factory productivity savings | $679K to $3.2M | Improved uptime, reduced overtime, better utilization |

Manufacturing efficiency drives measurable improvements across every aspect of factory operations. Companies that focus on manufacturing productivity see gains in cost savings, quality, and agility. Smart factories use sensors and real-time data analytics to enable proactive maintenance, reduce operating costs, and improve process efficiency. Predictive maintenance powered by IoT sensors helps reduce unplanned downtime and material costs. Enhanced connectivity, such as 5G, supports faster data transmission and better equipment lifespan optimization.

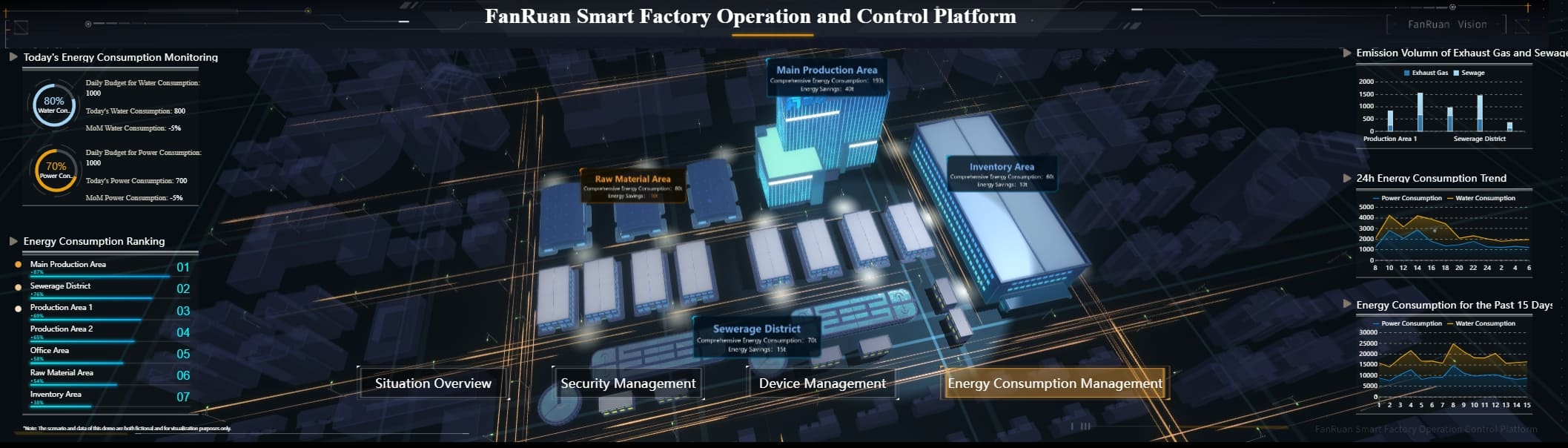

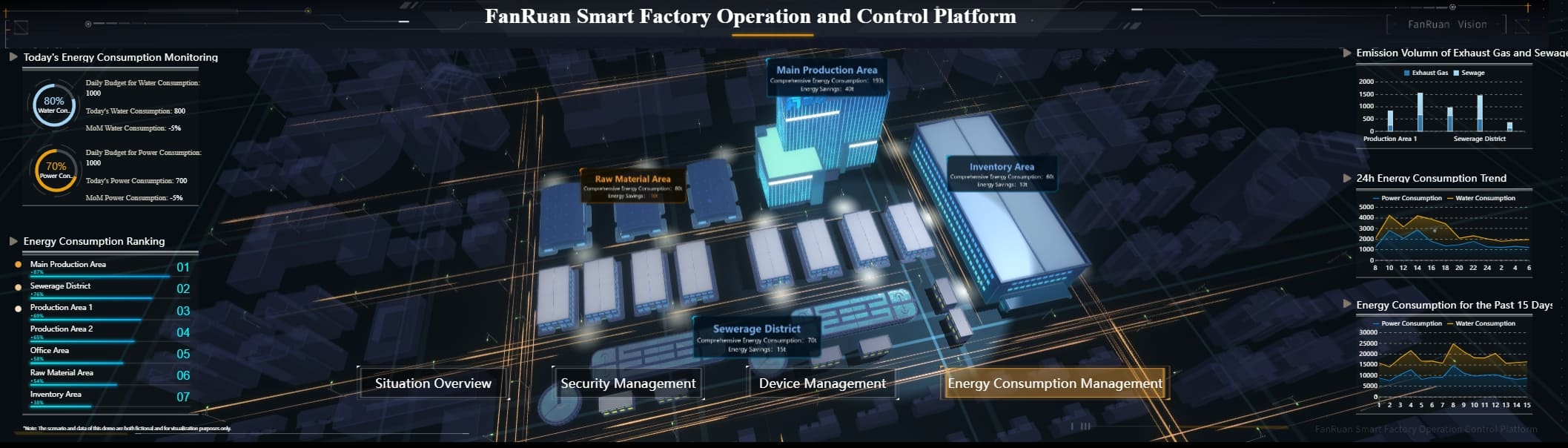

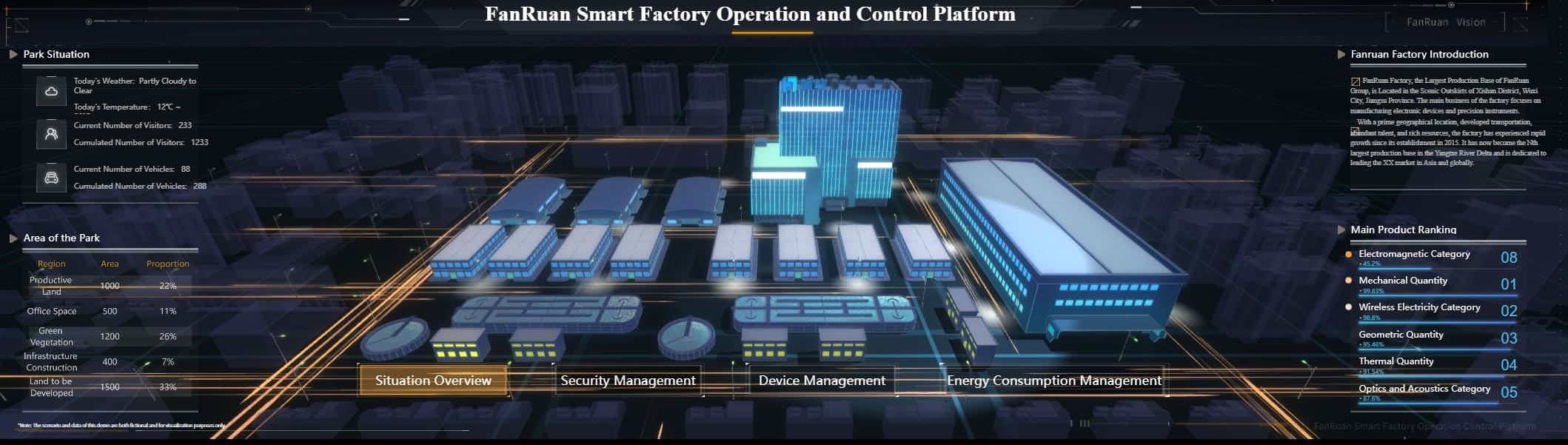

Below is a real-time factory facilities control dashboard by FineBI.

Quality management methods adapted from manufacturing, like Quality Improvement Collaboratives, have shown significant results. Seventy-three percent of these initiatives reported improvements in clinical practices, infection control, and prevention of adverse events. The Cost of Quality framework highlights that world-class manufacturers spend less than 5% of total sales on quality costs, while laggards spend over 20%. Managing and reducing poor quality costs leads to higher profit margins, improved customer trust, and better regulatory compliance.

Manufacturing efficiency also accelerates innovation. Automation allows workers to focus on priorities and complete projects faster. AI-driven automation reduces human error and increases productivity by automating routine tasks. Companies like BMW, Siemens, and GM have reported efficiency increases of 20%, 15%, and 30% reductions in material waste, respectively.

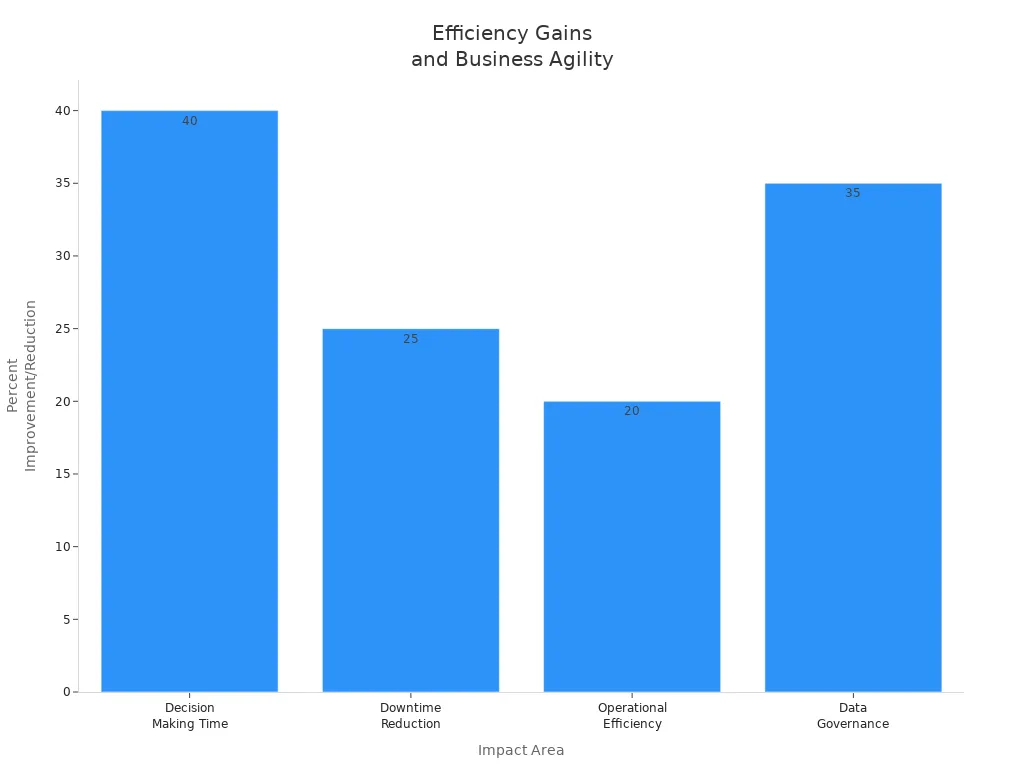

Tip: Real-time analytics and strong data governance support faster decision-making and operational efficiency, helping manufacturers boost factory productivity and adapt quickly to market changes.

| Impact Area | Evidence / Statistic | Explanation |

|---|---|---|

| Decision Making Time | 40% reduction in decision making time using real-time data systems | Faster, data-driven decisions enhance agility by enabling quicker responses to market changes. |

| Downtime Reduction | 25% reduction in downtime with real-time analytics | Less downtime improves operational responsiveness and agility. |

| Operational Efficiency | 20% improvement in operational efficiency with real-time analytics | Efficiency gains support faster adaptation and agility. |

| Data Governance | 35% reduction in time spent on data validation with strong data governance | Reliable data speeds up decision making and reduces errors, supporting agility. |

| Digital Transformation | Integration of ERP and advanced scheduling systems improves supply chain responsiveness | Digital tools build a foundation for agility by enabling swift adaptation to market conditions. |

| Continuous Improvement | Culture of innovation and experimentation fosters adaptability and efficiency | Encourages ongoing process optimization, critical for maintaining agility. |

Inefficient manufacturing processes expose companies to serious risks. Contamination from poor cleaning or storage leads to product defects and safety hazards. Process variability causes inconsistent product quality, often resulting from inconsistent machine performance or operator techniques. Overproduction, driven by inaccurate demand forecasting, creates excess stock and increases storage costs.

Common risks include:

Manufacturing productivity suffers when companies ignore these risks. Factories that fail to address inefficiency struggle to boost factory productivity and maintain competitiveness.

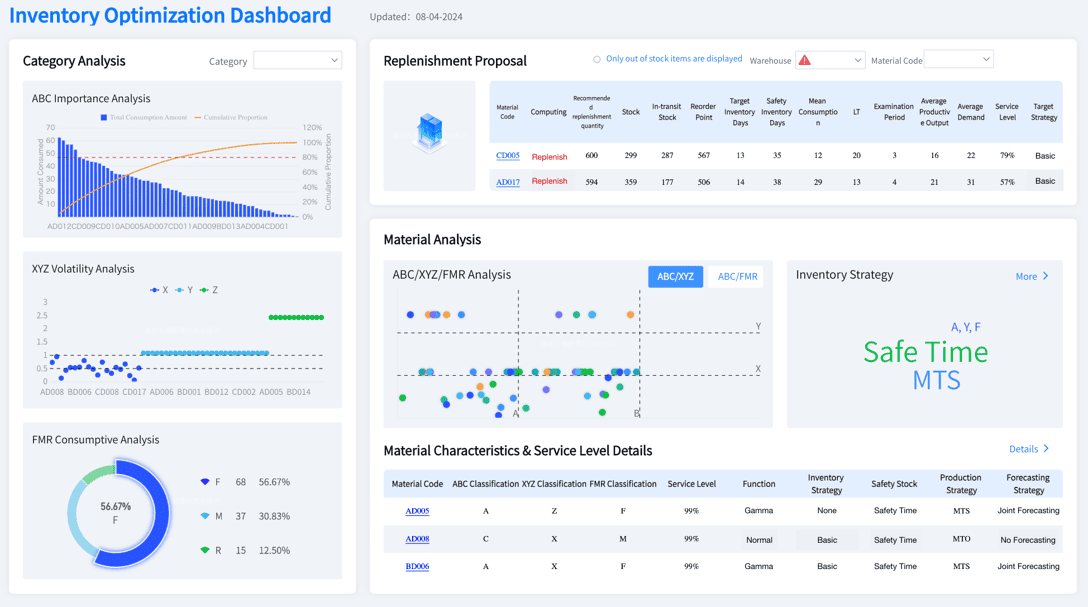

Below is a inventory optimization dashboard created by FineBI.

Manufacturing leaders recognize that process optimization is the foundation for sustainable gains in manufacturing productivity. Companies that focus on lean manufacturing principles, workflow design, and standardization consistently achieve higher operational efficiency, lower costs, and improved product quality. This section explores how these strategies help organizations improve manufacturing productivity and increase productivity in manufacturing.

Lean manufacturing principles drive continuous improvement and waste elimination across the manufacturing process. Organizations identify value by removing non-value-added activities such as overproduction, waiting, unnecessary transport, excess inventory, and defects. These efforts streamline processes and reduce lead times.

Key lean manufacturing principles include:

Real-world examples highlight the impact of lean manufacturing principles:

Toyota exemplifies lean manufacturing principles through its Toyota Production System. The company integrates lean principles into every department, emphasizing continuous improvement and employee involvement. This approach makes lean a core organizational value.

Lean manufacturing principles deliver measurable results:

Optimizing workflow design is essential for manufacturing productivity. Companies that optimize workflows achieve faster production cycles, higher output, and lower costs. Workflow design focuses on streamlining operations, reducing waste, minimizing errors, and improving resource utilization.

Key strategies to optimize workflows include:

Actionable steps for improving workflow design:

| Actionable Step / Technique | Description | Ideal Manufacturing Process Types |

|---|---|---|

| Process Standardization | Establish clear SOPs and work instructions to ensure consistent quality and reduce errors. | Repetitive manufacturing, Discrete manufacturing |

| Automation and System Integration | Use machines and Industry 4.0 tech to automate tasks and optimize workflows. | Repetitive manufacturing, Continuous manufacturing |

| Ergonomics and Workstation Design | Design workspaces to reduce fatigue and accidents, improving productivity. | Batch manufacturing, Job shop manufacturing |

| Production Flow Management | Optimize material and information flow using Kanban and Just-in-Time. | Batch manufacturing, Discrete manufacturing |

| Improvement by Design | Simplify product design to reduce components and streamline manufacturing. | Discrete manufacturing, Job shop manufacturing |

| Preventive and Predictive Maintenance | Use data-driven maintenance to prevent machine breakdowns. | All process types |

| Process Mapping and Data Collection | Use visual tools to identify inefficiencies and guide improvements. | All process types |

Manufacturers monitor workflow performance by tracking KPIs such as task completion times, error rates, and compliance. Regular reviews and adjustments maintain efficiency and relevance. Clear communication and collaboration among workflow participants reduce errors and misunderstandings. Thorough documentation of workflow steps ensures consistency. Workflow management software automates compliance checks and supports data-driven decision-making.

Organizations applying data-driven process improvement report productivity gains of 20-30% across operations. Defect rates can be reduced by up to 40%, leading to higher customer satisfaction and loyalty. These statistics demonstrate measurable productivity improvements following process optimization.

Standardization is a powerful strategy to improve manufacturing productivity. Companies that standardize processes achieve consistent quality, reduce errors, and increase operational efficiency. Standardization involves establishing clear procedures, work instructions, and best practices for every manufacturing process.

Evidence supports the effectiveness of standardization:

| Evidence Type | Description | Impact/Result |

|---|---|---|

| Defect Rate Reduction | Manufacturing company standardized assembly line processes | Over 30% reduction in defect rates |

| Inventory Accuracy | Retail chain standardized inventory management and training | 25% reduction in stock discrepancies |

| Process Variability | Standardization reduces variability, directly increasing process efficiency | Efficiency ∝ 1/Variability (inverse relation) |

| Regulatory Compliance | Standardized procedures ensure compliance with industry standards | Improved audit outcomes and market reputation |

| KPIs for Monitoring | Use of KPIs such as cycle time, error rates, productivity, and customer satisfaction scores | Quantifiable continuous improvement |

Effective standardization requires robust, sustainable processes reinforced by a culture of continuous improvement. Supervisors engage directly with operators through Gemba walks and real-time feedback to ensure standards are known, applied, and effective. Continuous feedback loops and training maintain and improve standardized processes over time.

Manufacturers benefit from standardization through improved margins, productivity, cost reduction, streamlined operations, and an empowered workforce. Standardization also supports regulatory compliance and enhances market reputation.

Process optimization strategies such as lean manufacturing, Six Sigma, automation, and real-time data utilization help leading manufacturers reduce costs, improve product quality, and increase productivity. Facility layout optimization further improves workflow and reduces unnecessary movement, contributing to faster turnaround times.

Organizations that optimize workflows and standardize processes consistently achieve higher manufacturing efficiency. These strategies help companies improve manufacturing productivity, increase productivity in manufacturing, and maintain a competitive edge.

Digitalization, automation, and advanced analytics have transformed manufacturing productivity. Companies now rely on smart technologies to boost factory productivity, streamline operations, and achieve higher levels of efficiency. This section explores how automation, real-time data integration, and analytics drive manufacturing efficiency and support sustainable growth.

Manufacturers deploy automation and robotics to increase factory productivity and reduce costs. Robots perform repetitive and dangerous tasks, allowing workers to focus on higher-value activities. Automation ensures consistent quality and precision, operating continuously without fatigue.

Recent advancements in robotics include:

| Impact Aspect | Evidence Summary |

|---|---|

| Labor Cost Reduction | Robotics reduce labor hours drastically (e.g., 300 hours vs. 1,600 hours per aircraft), lowering labor costs and injuries. |

| Production Speed | Robots operate continuously without fatigue, speeding up production and reducing lead times. |

| Scalability | Robots enable quick scaling of production up or down, adapting to demand changes efficiently. |

| Productivity & Efficiency | Robots work nonstop with consistent quality, increasing output and reducing errors. |

| Benefit Category | Evidence Summary |

|---|---|

| Lowered Operating Costs | Robots replace multiple workers, reducing labor expenses and energy costs. |

| Reduced Lead Times | Automation keeps processes in-house and continuous, shortening production lead times. |

| Increased Production Output | Robots work 24/7 at constant speed, enabling higher production volumes. |

| Increased Productivity | Automation allows one worker to manage multiple machines, boosting overall efficiency. |

Robotics integration leads to higher manufacturing productivity. Robots adapt quickly to changing production demands, accelerating production speed and reducing costs. Companies that invest in automation see measurable improvements in factory productivity, safety, and scalability.

Note: Automation and robotics not only boost factory productivity but also support safer workplaces and flexible production strategies.

Real-time data integration has become essential for manufacturing efficiency. Manufacturers use platforms like FanRuan to connect diverse data sources, synchronize information, and eliminate data silos. FineDataLink, a core solution from FanRuan, enables real-time incremental data synchronization, ETL/ELT processes, and API publishing.

| Benefit | Explanation |

|---|---|

| Predictive Maintenance | Real-time sensor data and algorithms predict equipment failures, preventing breakdowns and reducing repair costs. |

| Improved Product Quality | Continuous monitoring and immediate alerts enable quick corrections, ensuring consistent quality and fewer defects. |

| Increased Operational Efficiency | Real-time monitoring reduces downtime and optimizes resource use by detecting anomalies early. |

| Cost Savings | Predictive maintenance and waste reduction lower maintenance expenses and material costs. |

| Benefit | Explanation |

|---|---|

| Faster Time to Market | Real-time data enables better collaboration and up-to-date information sharing, accelerating product development and reducing disruptions. |

| Optimized Inventory Management | Real-time data allows accurate demand forecasting and responsive inventory control, reducing excess stock and overproduction. |

| Enhanced Compliance & Accuracy | Automated data collection and real-time machine health monitoring improve regulatory compliance and data reliability. |

| Reduced Operational Costs | Automation and improved collaboration lower manual errors and optimize resource allocation, cutting production costs. |

FineDataLink connects efficiently to ERP, MES, and SRM systems, supporting real-time insights on a unified platform. Low-code functionality simplifies integration and eliminates data silos. Manufacturers consolidate data into interactive dashboards for comprehensive visualization and analysis. These capabilities transform raw manufacturing data into actionable insights, supporting timely decision-making and cross-departmental alignment.

| Feature/Workflow | Description |

|---|---|

| FineDataLink Core Functionality | Connects efficiently to diverse data sources, supports real-time incremental data synchronization from entire databases or multiple tables, and breaks data silos through ETL/ELT processes and Data Service API publishing. |

| Integration with FineBI | IT staff use FineDataLink to clean and integrate data, outputting business-wide tables for analysis and dashboard creation in FineBI, reducing redundancy and shortening data update times. |

| Integration with FineReport | FineDataLink processes complex SQL and cross-database data, outputs results to application databases, simplifying report development and accelerating dashboard display in FineReport. |

Manufacturers that leverage real-time data integration platforms achieve faster decision-making, improved customer experience, and increased operational efficiency. Unified data views break down silos, foster collaboration, and support comprehensive insights. Scalability and flexibility allow companies to handle growing data volumes and integrate new sources, supporting business growth and higher profitability.

Advanced analytics play a critical role in improving manufacturing decision-making. FineBI, a self-service business intelligence platform from FanRuan, empowers manufacturers to transform raw data into actionable insights. Managers use analytics to identify bottlenecks, forecast trends, and optimize processes.

Analytics enables real-time monitoring and analysis of production processes, helping identify inefficiencies and bottlenecks to optimize workflows and reduce downtime. Predictive maintenance uses sensor data to forecast equipment failures, allowing proactive interventions that minimize disruptions and costs. Quality control is enhanced by detecting anomalies and tracing defects to root causes, improving product consistency and reducing waste.

FineBI supports manufacturing analytics by enabling scheduled task email notifications, such as sending daily sales analysis dashboards to decision-makers. This feature ensures that key stakeholders receive up-to-date performance data automatically, facilitating timely and informed decisions. FineBI also provides matrix correlation analysis methods that help decision-makers prioritize and address primary issues before secondary ones. This approach improves work efficiency by guiding resource allocation to departments or tasks with the greatest potential impact.

Manufacturers use analytics to optimize supply chains, improve inventory management, and reduce costs. Data-driven decision-making provides comprehensive insights into operations, market trends, and customer preferences, aligning decisions with business goals. Analytics supports innovation by analyzing market trends and customer feedback to develop competitive products and optimize designs.

Tip: Companies that invest in analytics platforms like FineBI consistently achieve higher manufacturing productivity, reduce downtime, and improve product quality.

Digitalization, automation, and analytics collectively boost factory productivity and support sustainable industrial upgrading. Manufacturers that embrace these technologies gain a competitive edge, improve quality, and achieve measurable gains in factory productivity.

Manufacturers rely on precise metrics to evaluate and improve operational efficiency. Overall Equipment Effectiveness (OEE) stands as a primary indicator. OEE combines performance, quality, and availability to show how well equipment produces first-quality products during scheduled time. Performance measures actual machine run time against downtime. Quality tracks the percentage of units produced without defects. Rate compares actual speed to the ideal standard.

Other important metrics include:

| Metric | What It Measures | Why It Matters |

|---|---|---|

| OEE | Productive time (performance, quality, availability) | Identifies bottlenecks and losses |

| Production Volume | Total units produced | Benchmarks output |

| Downtime | Non-operating time | Highlights process interruptions |

| Production Costs | Labor, materials, overhead | Guides cost reduction strategies |

| First Time Right | Correct products without rework | Indicates process stability |

Accurate data collection and standardized definitions ensure meaningful measurement. These key performance indicators help manufacturers track resource utilization, production goals, and output quality.

Continuous improvement drives lasting gains in manufacturing. Manufacturers adopt a culture of frequent, small changes that add up to major progress. This approach encourages experimentation, reduces waste, and improves product quality. Teams collaborate across departments, sharing ideas and innovations.

Programs such as PDCA, Six Sigma, Kaizen, and Lean methodologies guide iterative problem-solving. Companies identify areas for improvement, set measurable goals, engage employees, and leverage digital tools. Training supports skill development, while KPIs measure progress.

General Electric applied digital lean manufacturing and achieved up to 35% cost reductions on parts in ten months. This example shows how continuous improvement accelerates operational efficiency and delivers rapid results.

Successful programs use robust measurement systems. Metrics focus on quality, time, cost, and employee engagement. Real-time monitoring and root cause analysis help teams address issues quickly. Continuous improvement reduces defects, lowers costs, and increases innovation. Employees feel more engaged, and customers benefit from higher quality products.

Tip: Structured continuous improvement programs help manufacturers sustain efficiency gains and adapt to changing market demands.

Manufacturing leaders achieve lasting efficiency by adopting proven strategies and embracing digital transformation. Key approaches include:

To move forward, manufacturers can:

By taking these steps, organizations position themselves for greater efficiency and data-driven growth. Explore FineBI to unlock new levels of manufacturing productivity.

Data Analytics Meaning Explained for Modern Businesses

What is Manufacturing Engineering and Why is it Essential in Malaysia

Use Diagnostic Analytics for Smarter Business Decisions in Malaysia

Unlocking Business Growth with Retail Analytics

The Author

Lewis

Senior Data Analyst at FanRuan